Method for preparing green-light and transparent ceramic phosphor applied to high-photosynthetic-efficiency LED

A technology of transparent ceramics and phosphors, which is applied in the field of preparation of green light transparent ceramic phosphors, can solve problems such as poor thermal stability, achieve the effects of maintaining uniformity, high control precision, and broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Press (Ce 0.1% Lu 99.9% ) 3 al 5 o 12 Chemical composition weighing α-Al 2o 3 Powder, Lu 2 o 3 Powder, CeO 2 The powder raw material is 25g in total, add 0.1200g of TEOS, 1.1000g of fish oil into a high-purity agate ball mill jar, add 80g of high-purity alumina balls, 5g of absolute ethanol, 10g of xylene, and ball mill for 20h; then add poly Vinyl butyral 1.7g, fatty acid 1.7g, ball milled for 20h; after ball milling, pour it into a defoaming machine to defoam for 20min, and then cast it through a casting machine to obtain a cast layer of 600 microns; prepare ten layers (see figure 1 , where N=10) (Ce 0.1% Lu 99.9% ) 3 al 5 o 12 The cast layers are stacked to form a ceramic cast sheet, put into a dry press mold at 110°C for 10 hours, pressurize in one direction with a pressure axis of 20Mpa to form a non-layered integral ceramic block, and cold isostatically press at 200Mpa; cast The green body is degreased in an oxygen atmosphere at a heating rate of 1.5...

Embodiment 2

[0046] Press (Ce 0.5% Lu 99.5% ) 3 al 5 o 12 Chemical composition weighing α-Al 2 o 3 Powder, Lu 2 o 3 Powder, CeO 2 The powder raw material is 25g in total, the balls are 75g of zirconia balls, 8g of ethanol, 8g of xylene, 0.2500g of sintering aid MgO, 1.5g of dispersant oleic acid, the two ball milling times are 24h and 12h respectively; the dry pressure is 25MPa, The cast body was degreased in an oxygen atmosphere, the heating rate was 2°C / min, the temperature was raised to 800°C and kept for 30 hours, and the sintering time was 15 hours. Other conditions were the same as in Example 1, and a green transparent ceramic phosphor was obtained. The visible light transmittance 80.2%, quantum efficiency: 97.5%.

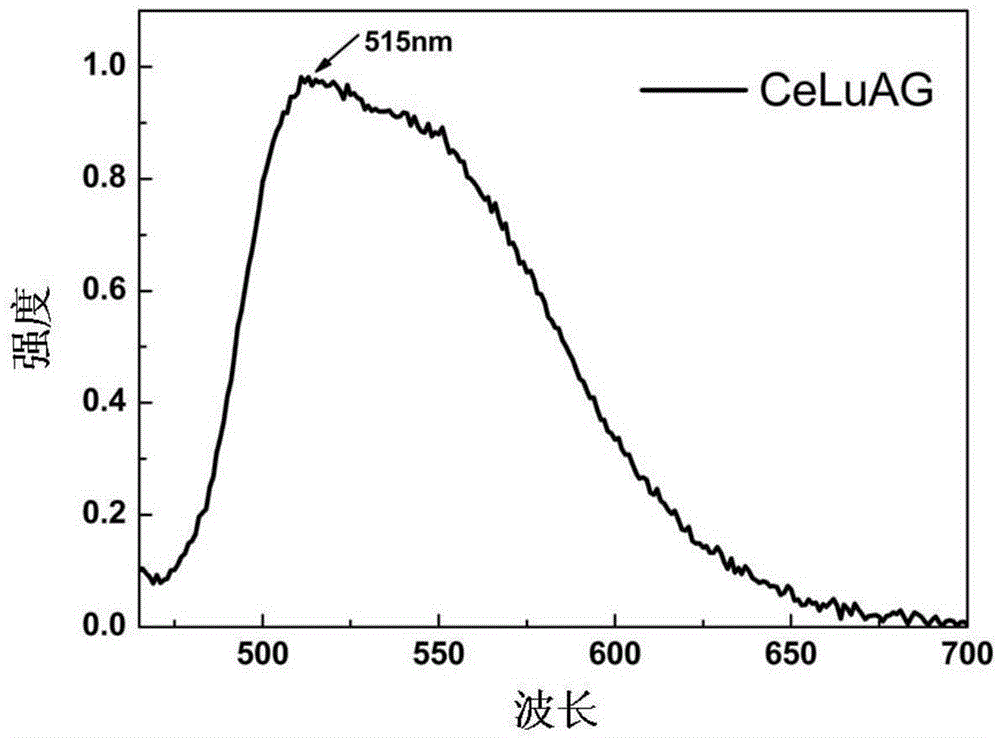

[0047] The green light transparent ceramic phosphor prepared in this embodiment is driven by a constant current of 20mA, and the performance indicators obtained by the 460nm blue light chip excitation test are as follows (see figure 2 ):

[0048] Light effect:...

Embodiment 3

[0053] Press (Ce 1% Lu 99% ) 3 al 5 o 12 Chemical composition weighing α-Al 2 o 3 Powder, Lu 2 o 3 Powder, CeO 2 A total of 25g of powder raw materials, 75g of alumina balls, alumina cans, 10g of ethanol, 6g of xylene, 0.1200g of TEOS and 0.0500g of MgO are used as sintering aids. The two ball milling times are 24h and 8h respectively; The conditions were the same as in Example 1, and a green light transparent ceramic phosphor was obtained, the visible light transmittance was 78.9%, and the quantum efficiency was 96.9%.

[0054] The green light transparent ceramic phosphor prepared in this example is driven by a constant current of 20mA, and the performance index obtained by the excitation test of a 460nm blue light chip is as follows:

[0055] Light effect: 157lm / W

[0056] Color coordinates: (0.3891, 0.5639)

[0057] Emission peak: 543nm.

[0058] It can be seen that the white light LED described in the present invention has high luminous efficiency, which is suf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com