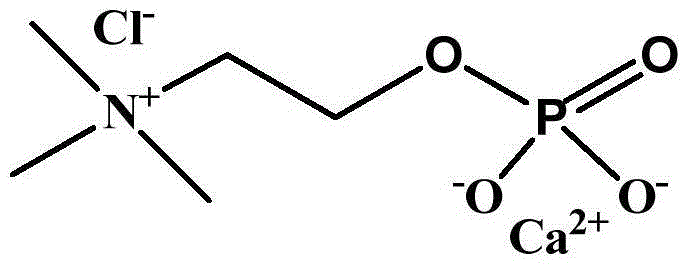

Method for preparing phosphocholine chloride calcium salt tetrahydrate

A technology for phosphoryl choline chloride calcium salt and phosphoryl choline chloride is applied in the field of preparation of phosphoryl choline chloride calcium salt tetrahydrate, can solve problems such as environmental pollution, and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a preparation method of phosphorylcholine chloride calcium salt tetrahydrate, the preparation method comprising:

[0019] 1) Phosphorylating the crude choline chloride product with a phosphorylating reagent to obtain a phosphorylcholine chloride mixture;

[0020] 2) performing a metathesis reaction on the phosphorylcholine chloride mixture and the calcium source aqueous solution to obtain a metathesis mixture;

[0021] 3) The metathesis mixture is subjected to vacuum distillation to separate out a solid to obtain a solid-liquid mixture;

[0022] 4) crystallizing, filtering and drying the solid-liquid mixture at -10°C to -1°C to obtain phosphorylcholine chloride calcium salt tetrahydrate;

[0023] Wherein, the phosphorylation reagent is selected from phosphoric acid and / or polyphosphoric acid; the calcium source aqueous solution is selected from one or more of calcium chloride aqueous solution, calcium carbonate aqueous solution, calcium hydroxide...

Embodiment 1

[0037] 1) At 25°C and -0.09MPa, slowly add 140g of phosphoric acid dropwise (the drop rate is 10 drops / s) to 100g of choline chloride crude product (containing 70% choline chloride), after the dropwise addition is completed The temperature was raised to 70°C for vacuum distillation until there was no distilled water, then the temperature was raised to 120°C and the pressure was controlled at -0.09MPa to react for 6h, and then 50g of water was added to terminate the reaction to obtain a phosphorylcholine chloride mixture;

[0038] 2) At 25° C., mix 100 g of the above-mentioned phosphorylcholine chloride mixture with 3000 g of calcium hydroxide aqueous solution (the mass fraction of calcium hydroxide is 15%) for 40 min until the pH of the system reaches 8 to obtain a metathesis mixture;

[0039] 3) At 25°C and 35Pa, the above-mentioned metathesis mixture was subjected to vacuum distillation until the solid was precipitated to obtain a solid-liquid mixture;

[0040] 4) Cool the a...

Embodiment 2

[0044] Carry out according to the method for implementing 1, change phosphoric acid into polyphosphoric acid when different.

[0045] The parameters of the infrared spectrum of the phosphorylcholine chloride calcium salt tetrahydrate are consistent with the standard infrared spectrum of the phosphorylcholine chloride calcium salt tetrahydrate; the elemental analysis results are consistent with the theoretical value.

[0046] In the present embodiment, the productive rate is 68%; wherein, step 4) obtains 100.2g phosphorylcholine chloride calcium salt tetrahydrate (purity is 100%); step 5) obtains 9.8g phosphorylcholine chloride calcium salt Salt tetrahydrate (99.5% pure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com