Cellulose/polyaniline nano-porous composite microspheres as well as preparation method and application thereof

A composite microsphere and nanoporous technology, which is applied in the field of polymer material science and technology, can solve the problems of high electrochemical performance and cycle stability, which cannot be satisfied, and achieves good rate capability, simple operation and high cycle stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

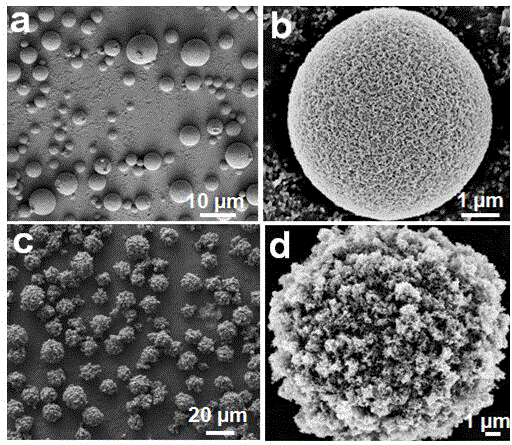

[0022] Dissolve 4.2g of cellulose cotton linters in 100g of LiOH / urea aqueous solution (the mass ratio of LiOH to urea is 4.6:15) precooled to -12.6°C to obtain a 4wt% cellulose solution, and centrifuge at 5°C at 7000rpm Degassing to obtain a transparent cellulose solution, then add 3ml of epichlorohydrin to 100g of cellulose solution in an ice-water bath at 0°C and stir for 2 hours to disperse the epichlorohydrin evenly, and finally in an ice-water bath at 0°C, Add 60g Span 80 to a 500ml three-neck flask, stir 300ml isooctane at a speed of 500r / min for 30min to disperse the emulsifier evenly, then stir at a speed of 1000r / min, add the above 60g 4wt% cellulose solution and stir for 30min, remove the ice bath and continue stirring After 2 hours, obtain pure cellulose balls with a maximum size distribution of 2um. After washing with deionized water and ethanol, soak 1g of cellulose balls in 100ml of 0.1mol / L aniline 10wt% phytic acid solution in an ice-water bath at 0°C 30min, t...

Embodiment 2

[0024] Dissolve 4.2g of cellulose cotton linters in 100g of LiOH / urea aqueous solution (the mass ratio of LiOH to urea is 4.6:15) precooled to -12.6°C to obtain a 4wt% cellulose solution, and centrifuge at 5°C at 7000rpm Degassing to obtain a transparent cellulose solution, then add 3ml of epichlorohydrin to 100g of cellulose solution in an ice-water bath at 0°C and stir for 2 hours to disperse the epichlorohydrin evenly, and finally in an ice-water bath at 0°C, Add 30g Span 80 to a 500ml three-neck flask, stir 300ml isooctane at a speed of 500r / min for 30min to disperse the emulsifier evenly, then stir at a speed of 1000r / min, add the above 60g 4wt% cellulose solution and stir for 30min, remove the ice bath and continue stirring After 2 hours, obtain pure cellulose balls with a maximum size distribution of 6um. After washing with deionized water and ethanol, soak 1g of cellulose balls in 100ml of 0.1mol / L aniline 10wt% phytic acid solution in an ice-water bath at 0°C 30min, t...

Embodiment 3

[0026] Dissolve 4.2g of cellulose cotton linters in 100g of LiOH / urea aqueous solution (the mass ratio of LiOH to urea is 4.6:15) precooled to -12.6°C to obtain a 4wt% cellulose solution, and centrifuge at 5°C at 7000rpm Degassing to obtain a transparent cellulose solution, then add 3ml of epichlorohydrin to 100g of cellulose solution in an ice-water bath at 0°C and stir for 2 hours to disperse the epichlorohydrin evenly, and finally in an ice-water bath at 0°C, Add 20g Span 80 to a 500ml three-neck flask, stir 300ml isooctane at a speed of 500r / min for 30min to disperse the emulsifier evenly, then stir at a speed of 1000r / min, add the above 60g 4wt% cellulose solution and stir for 30min, remove the ice bath and continue stirring After 2 hours, obtain pure cellulose balls with a maximum size distribution of 8um. After washing with deionized water and ethanol, soak 1g of cellulose balls in 100ml of 0.1mol / L aniline 10wt% phytic acid solution in an ice-water bath at 0°C 30min, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com