High-temperature-resistant methanation catalyst and preparation method thereof

A methanation catalyst, high temperature resistant technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Large-scale production, consumption of large organometallic solvents, etc., to achieve the effect of weakening the surface tension of the liquid, small grain size, and improving the anti-carbon performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

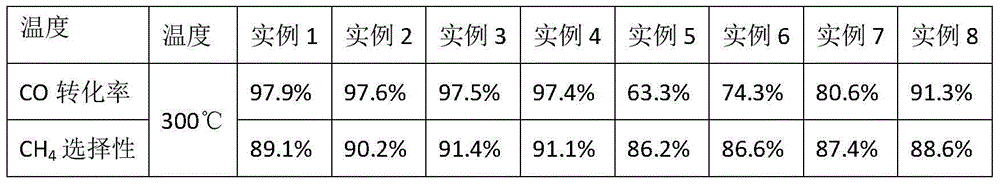

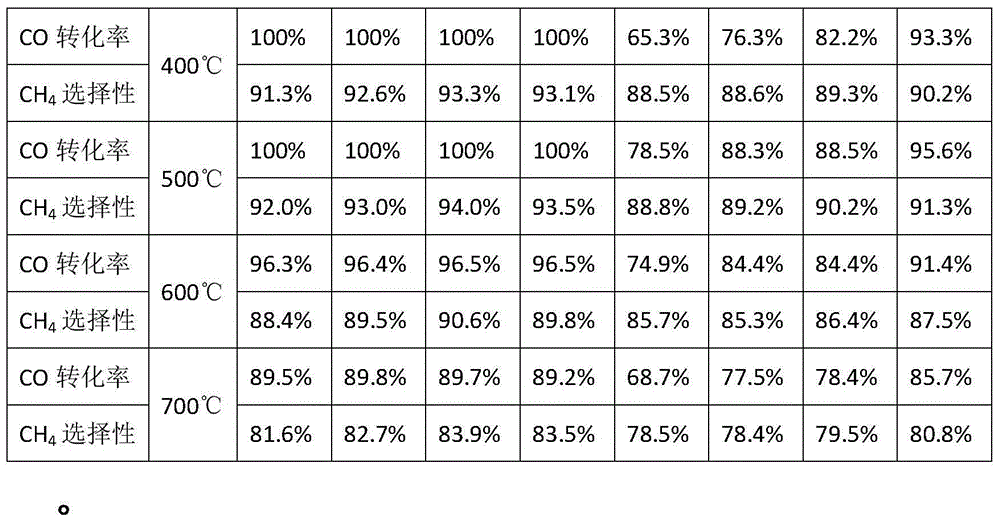

Examples

Embodiment 1

[0021] This embodiment includes the following steps:

[0022] A. Preparation of barium hexaaluminate carrier:

[0023] 90.03gAl(NO 3 ) 3 9H 2 O and 5.23g Ba(NO 3 ) 2 Dissolved in 400ml deionized water to form salt solution I, 30.7g (NH 4 ) 2 CO 3 Dissolve in 400ml ice-water bath to form alkali solution II, control 200ml mother liquor constant temperature water bath at 70°C, gradually add salt solution I and alkali solution II to the constantly stirring mother liquor for co-precipitation reaction, and maintain the mother liquor pH value at 7.5; after the precipitation reaction, age at 90°C for 2 hours under microwave conditions, wash the precursor solution with deionized water to remove excess ammonium salt; after suction filtration, dry the filter cake at 80°C for 1 hour under microwave radiation conditions, and roast at 450°C 4h, roast at 1300°C for 4h, cool to room temperature for later use. B. Introduction of active components:

[0024] 341.93Ni(NO) 3 ·6H 2 O an...

Embodiment 2

[0034] This embodiment includes the following steps:

[0035] A. Preparation of barium hexaaluminate carrier:

[0036] 90.03g Al(NO 3 ) 3 9H 2 O and 7.84g Ba(NO 3 ) 2 Dissolved in 400ml deionized water to form salt solution I, 32.67g (NH 4 ) 2 CO 3 Dissolve in 400ml ice-water bath to form alkaline solution II, control 200ml mother liquor constant temperature water bath at 80°C, gradually add salt solution I and alkali solution II to the constantly stirring mother liquor for co-precipitation reaction, and maintain the pH value of the mother liquor at 7.5; after the precipitation reaction, age at 90°C for 2h under microwave conditions, wash the precursor solution with deionized water to remove excess ammonium salt; after suction filtration, dry the filter cake at 80°C for 2h under microwave radiation, and roast at 500°C for 4h , 1300 ° C roasting 4h, cooled to room temperature for later use.

[0037] B. Introduction of active components:

[0038] 372.02gNi(NO) 3 ·6H ...

Embodiment 3

[0048] This embodiment includes the following steps:

[0049] A. Preparation of barium hexaaluminate carrier:

[0050] 90.03g Al(NO 3 ) 3 9H 2 O and 10.45g Ba(NO 3 ) 2 Dissolved in 400ml deionized water to form salt solution Ⅰ, 27.82g NH 4 HCO 3 Dissolve in 400ml ice-water bath to form alkali solution II, control 200ml mother liquor constant temperature water bath at 70°C, gradually add salt solution I and alkali solution II to the constantly stirring mother liquor for co-precipitation reaction, and maintain the mother liquor pH value at 7.5; after the precipitation reaction, age at 90°C for 2 hours under microwave conditions, wash the precursor solution with deionized water to remove excess ammonium salt; after suction filtration, dry the filter cake at 80°C for 2h under microwave radiation conditions, and roast at 600°C 2h, roast at 1200°C for 2h, cool to room temperature for later use.

[0051] B. Introduction of active components:

[0052] 402.11gNi(NO) 3 ·6H 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com