Nanometer titanium dioxide preparation method

A technology of nano-titanium dioxide and ammonium fluorotitanate, applied in the field of nano-materials, can solve problems such as the toxicity of chromium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The embodiment of the present invention discloses a preparation method of nano-titanium dioxide, comprising the following steps: mixing 20-50 parts by weight of absolute ethanol and 30-50 parts by weight of deionized water, adding boric acid and silver nitrate in sequence, and adding titanium fluoride after stirring ammonium acid, adjust the pH value between 2 and 4, and obtain the first solution after stirring; add a mixed solution of 20 to 30 parts by weight of butyl titanate and 30 to 70 parts by weight of absolute ethanol into the first solution, The second solution is obtained after stirring; add 4-12 parts by weight of titanate coupling agent and 2-5 parts by weight of polystyrene to the second solution, stir after ultrasonic dispersion, heat to 70-90°C, and continue stirring reaction and centrifugation to obtain nanometer titanium dioxide.

[0020] In the above technical scheme, the chemical formula of the ammonium fluorotitanate is (NH 4 ) 2 TiF 6 , the co-do...

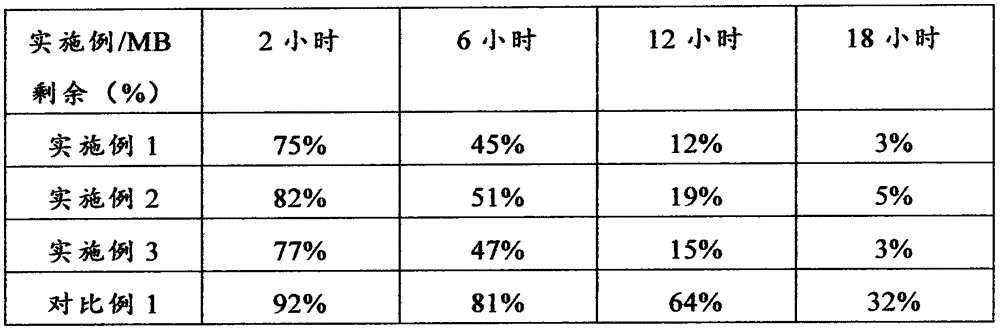

Embodiment 1

[0045] 1): Mix 50 parts of absolute ethanol and 40 parts of deionized water in parts by mass at room temperature. Add boric acid to make the concentration in the above solution about 0.3mol / L, add silver nitrate solution to make the concentration of silver nitrate in the above solution about 0.3mol / L, and stir for 3min.

[0046] 2): Add ammonium fluotitanate to the above mixed solution so that the concentration in the above solution is about 0.2mol / L, and adjust the pH between 2-4, and continue to stir for 15 minutes. This mixed solution is recorded as the first solution.

[0047] 3): Prepare mixed solution B, which is a mixed solution of 20 parts of butyl titanate and 40 parts of absolute ethanol. Add the mixed solution B into the first solution, control the addition rate to 1 mL / min, and stir for 1 h to obtain the second solution.

[0048] 4): Add 8 parts of titanate coupling agent and 4 parts of polystyrene to the second solution, ultrasonically disperse for 20 minutes, s...

Embodiment 2

[0052] 1): Mix 45 parts of absolute ethanol and 35 parts of deionized water in parts by mass at room temperature. Add boric acid so that its concentration in the above solution is about 0.35mol / L, add silver nitrate solution so that the concentration of silver nitrate in the above solution is about 0.2mol / L, and stir for 2 minutes.

[0053] 2): Add ammonium fluotitanate to the above mixed solution so that the concentration in the above solution is about 0.15mol / L, and adjust the pH between 2-4, and continue to stir for 20min. This mixed solution is recorded as the first solution.

[0054] 3): Prepare mixed solution B, which is a mixed solution of 30 parts of butyl titanate and 60 parts of absolute ethanol. Add the mixed solution B into the first solution, control the addition rate to 1.5 mL / min, stir for 1.5 h, and obtain the second solution.

[0055] 4): Add 4-12 parts of titanate coupling agent and 2-5 parts of polystyrene to the second solution, sonicate for 30 minutes, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com