Porous-ceramic with uniformly through ducts as well as preparation method and use of porous-ceramic

A technology of porous ceramics and channels, which is applied in the field of porous ceramics to achieve high filtration efficiency, good recycling ability, and easy to wash off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

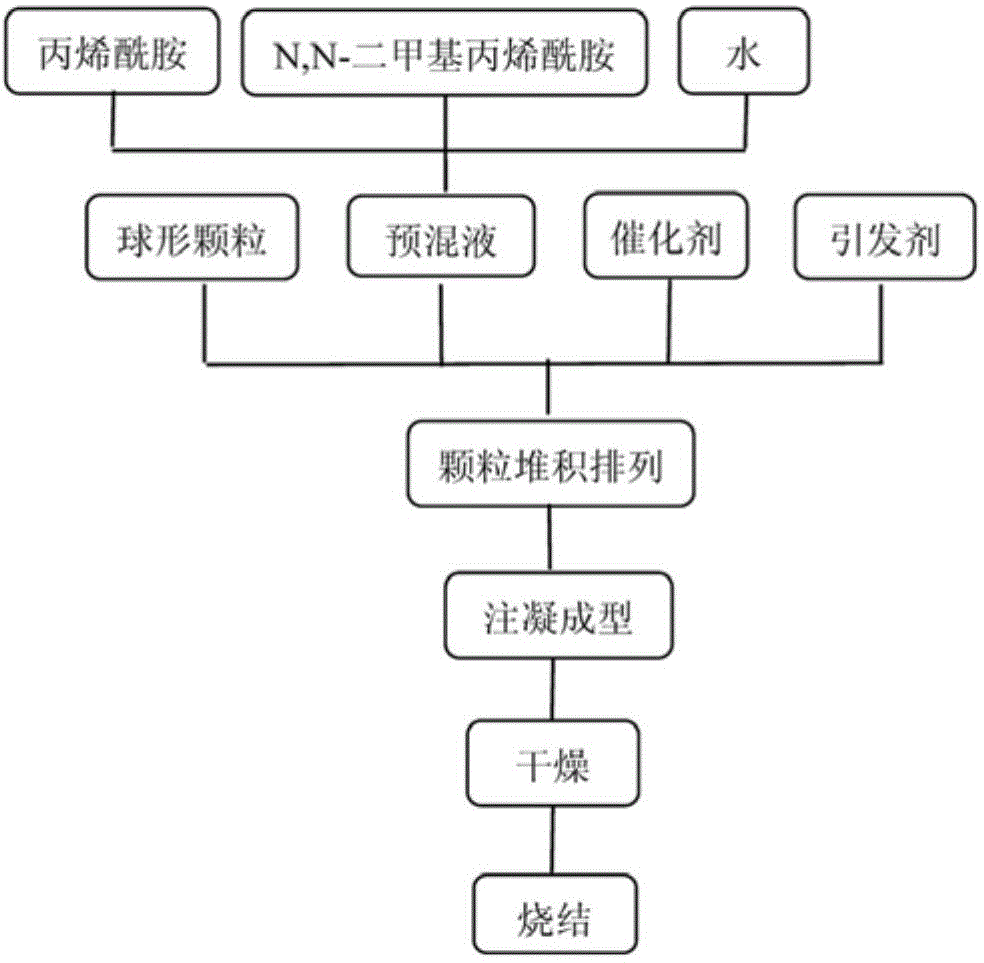

[0036] combined withfigure 1 The preparation process of the present invention is further described.

[0037] The flow chart of the preparation of porous ceramics with uniform pore size and three-dimensional penetration is shown in the attached figure 1 Shown:

[0038] (1) Dense spherical particles with low sintering activity refer to spherical particles whose specific surface area is close to the theoretical value, and these particles can be obtained by melting, especially by thermal plasma spheroidizing and melting.

[0039] (2) Preparation of the premix: prepare the premix according to 2-20 wt.% of the organic monomer, and the mass ratio of MBAM to the organic monomer is 1:30-1:10.

[0040] (3) Pour the premix into spherical particles, add catalyst and initiator, mix well, and use a specific method to achieve close packing of spherical particles. Of which (NH 4 ) 2 S 2 o 4 Occupying 3-10% of the mass fraction of organic monomers, (NH 4 ) 2 S 2 o 4 The mass ratio to...

Embodiment 1

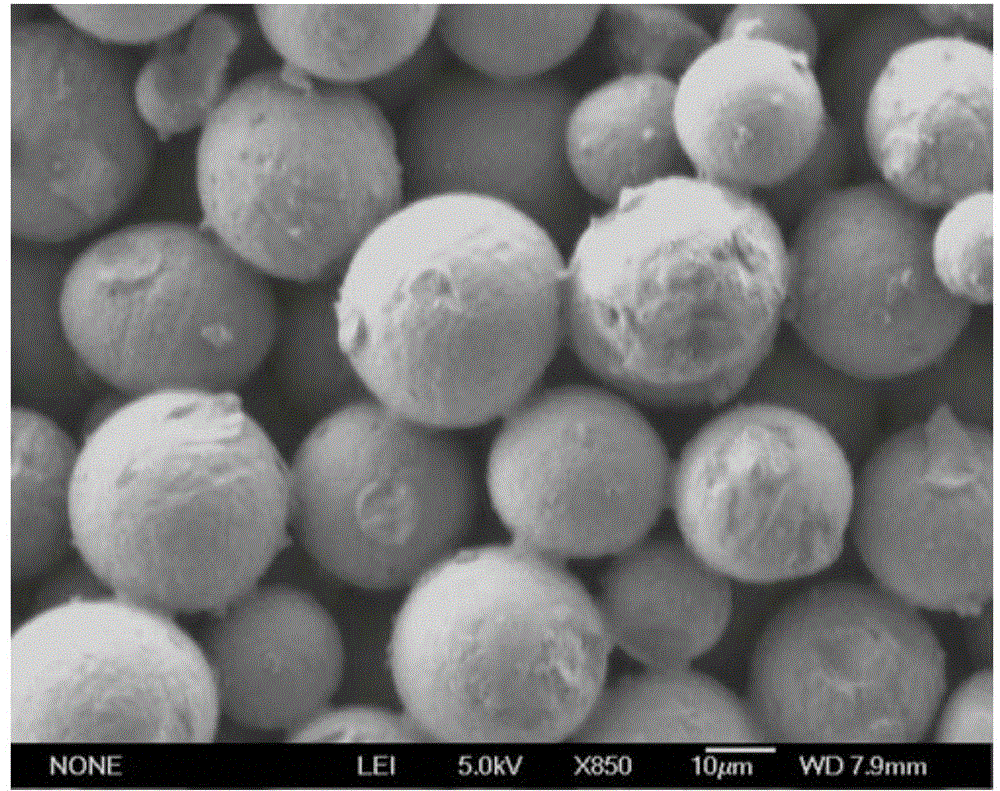

[0045] According to 2wt.% of organic monomer, the mass ratio of MBAM to organic monomer is 1:30, (NH 4 ) 2 S 2 o 4 Occupying 3% of the mass fraction of organic monomers, (NH 4 ) 2 S 2 o 4 The mass ratio with TEMED polyol is 1:1, and the mixed liquid is prepared. Pour the mixed solution into spherical silicon oxide particles with a particle size of 30 μm, control the amount of the premixed solution, configure it into a uniform slurry, place it at 80° C., and polymerize for 10 minutes. After the green body is dried, it is sintered at 1200°C for 2 hours to obtain a porous ceramic with an average pore diameter of 8 μm and a strength of 25 MPa.

Embodiment 2

[0047] According to 6wt.% of organic monomer, the mass ratio of MBAM to organic monomer is 1:20, (NH 4 ) 2 S 2 o 4 Occupying 5% of the mass fraction of organic monomers, (NH 4 ) 2 S 2 o 4 The mass ratio of TEMED polyol is 1:2, and the mixed liquid is prepared. Pour the mixed solution into spherical silicon oxide particles with a particle size of 50 μm, control the amount of the premixed solution, configure it into a uniform slurry, place it at 70° C., and polymerize for 20 minutes. After the green body is dried, it is sintered at 1200° C. for 2 hours to obtain a porous ceramic with an average pore diameter of 15 μm and a strength of 15 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com