Application method of nano antimicrobial primer

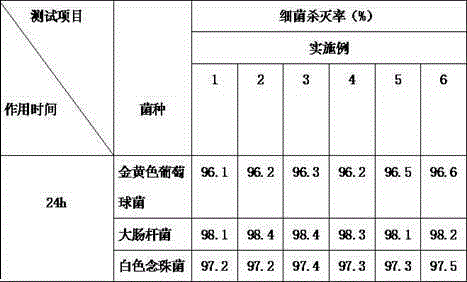

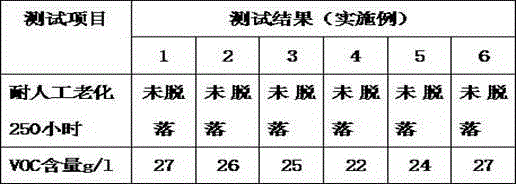

A primer and nano technology, applied in the field of coatings, can solve the problems of easy breeding of bacteria, no sterilization of primer, antibacterial function, affecting human health, etc., and achieve the effect of strong antibacterial performance, low VOC content, and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The using method of the nano antibacterial primer of the present invention: fully stir the nano antibacterial primer evenly, add an appropriate amount of diluent 20% to dilute to the required viscosity, calculate every liter of nano antibacterial primer with 50 μm dry paint film and brush 15kg / m 2 , then dry for 15 minutes, and cure to obtain the coating;

[0022] The nano-antibacterial primer is composed of the following raw materials according to the ratio of parts by weight: 40 parts of silicone modified acrylic resin, 10 parts of nano-titanium dioxide, 2 parts of titanium dioxide, 15 parts of nano-calcium carbonate, 2 parts of polyvinyl alcohol, and 9 parts of propylene glycol methyl ether , 3 parts of fumed silica, 25 parts of deionized water.

Embodiment 2

[0024] The using method of the nano antibacterial primer of the present invention: fully stir the nano antibacterial primer evenly, add an appropriate amount of diluent 30% to dilute to the required viscosity, calculate every liter of nano antibacterial primer with 50 μm dry paint film and brush 18kg / m 2 , and then dry for 25 minutes, curing to get the coating;

[0025] The nano antibacterial primer is composed of the following raw materials according to the ratio of parts by weight: 30 parts of epoxy modified acrylic resin, polyester modified acrylic resin, 20 parts of nano silver, 10 parts of titanium dioxide, 5 parts of nano talc, 8 parts of polyvinylpyrrolidone parts, 3 parts of dipropylene glycol propyl ether, 12 parts of polyolefin wax, and 35 parts of deionized water.

Embodiment 3

[0027] The using method of the nano antibacterial primer of the present invention: fully stir the nano antibacterial primer evenly, add an appropriate amount of diluent 25% to dilute to the required viscosity, calculate every liter of nano antibacterial primer with 50 μm dry paint film and brush 16kg / m 2 , and then dry for 18 minutes, curing to get the coating;

[0028] The nano antibacterial primer is composed of the following raw materials according to the ratio of parts by weight: 35 parts of polyester modified acrylic resin, 14 parts of nano magnesium hydroxide, 6 parts of titanium dioxide, 9 parts of nano mica powder, 5 parts of polyethylene oxide, ten parts of alcohol ester Two 6 parts, polyamide wax 8 parts, deionized water 30 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com