Preparation method for preparing hydrophilic quantum dots based on novel amphiphilic polymer ultrasonic emulsion process

An amphiphilic and polymer technology is applied in the field of preparation of new amphiphilic polymer ultrasonic emulsion method to prepare hydrophilic quantum dots. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

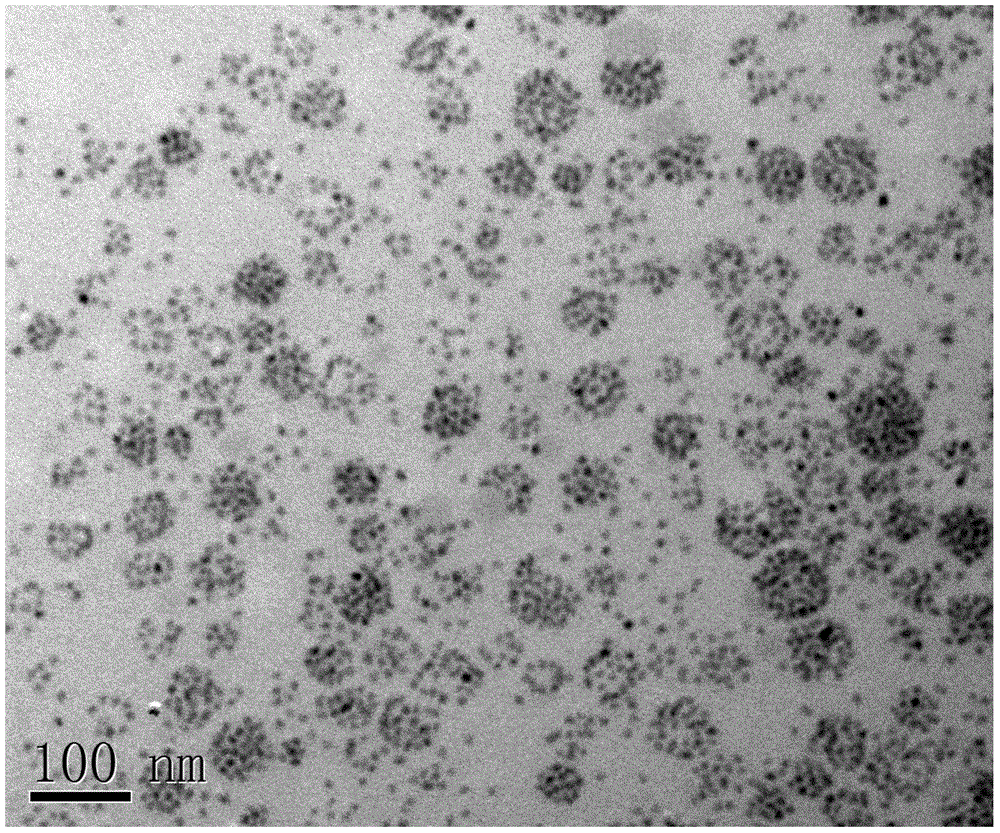

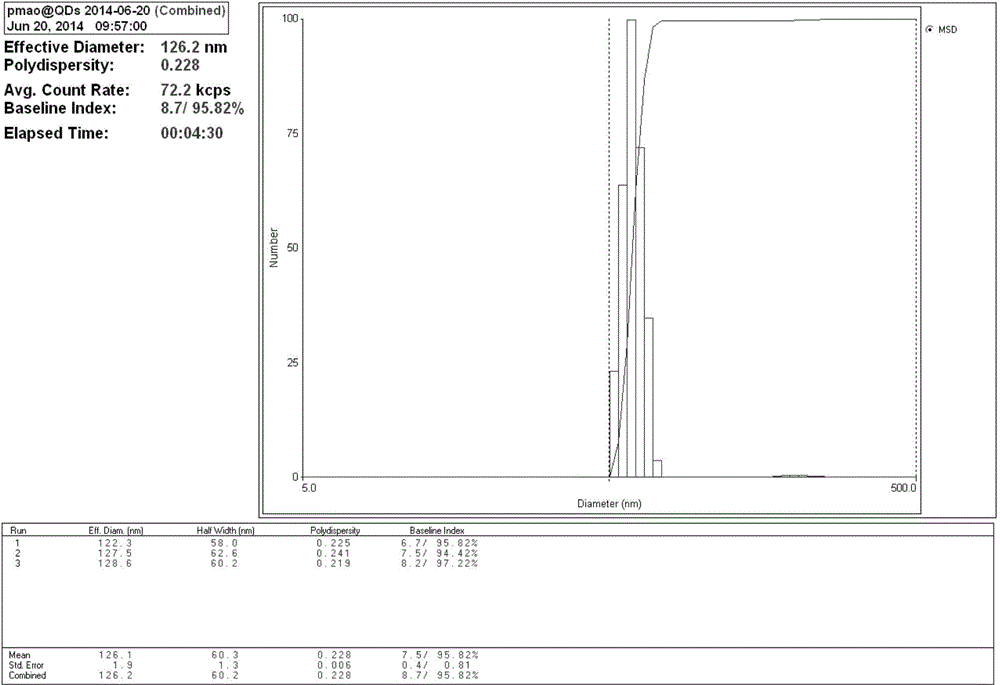

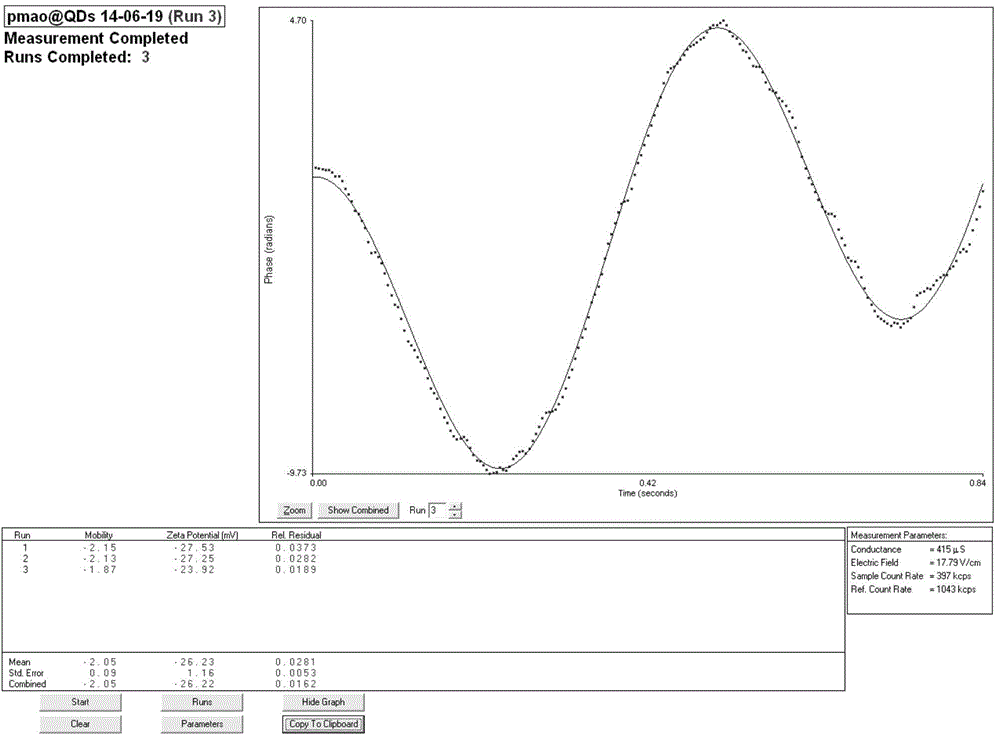

[0030] Implementation Case 1: Based on the novel polymaleic anhydride-alt-1-octadecene phacoemulsification modified quantum dots.

[0031] 1) 0.4mg polymaleic anhydride-alt-1-octadecene (Poly(maleic anhydride-alt-1-octadecene), PMAO) and 100uL quantum dot QDs are added to the reactor (mass fraction ratio is 50: 1), then add 200uL methylene chloride to the reactor to form an oil phase whose polymaleic anhydride-alt-1-octadecene concentration is 2mg / mL;

[0032] 2) Add 40uL ring-opener 2,2′-(ethylenedioxy)bis(ethylamine) to the reactor, and then add 4mL deionized water to the reactor to form 2,2′-(ethylenedioxy)bis (Ethylamine) concentration is the aqueous phase of 10uL / mL;

[0033] 3) Evenly drop the above-mentioned oil phase into the above-mentioned water phase to form a water-oil uniform emulsion dispersion system, wherein the volume ratio of the oil phase and the water phase is adjusted to 1:20, and ultrasonic dispersion is performed with an ultrasonic disperser, and the ul...

Embodiment example 2

[0036] Implementation Case 2: Based on the novel polymaleic anhydride-alt-1-octadecene ultrasonic emulsification modified quantum dots.

[0037]1) Add 0.8mg polymaleic anhydride-alt-1-octadecene (Poly(maleic anhydride-alt-1-octadecene), PMAO) and 100uL quantum dots to the reactor (the mass fraction ratio is 100:1 ), then in the reactor, add 400uL methylene chloride to form the oil phase that polymaleic anhydride-alt-1-octadecene concentration is 2mg / mL;

[0038] 2) Add 80uL ring-opener 2,2′-(ethylenedioxy)bis(ethylamine) to the reactor, and then add 8mL deionized water to the reactor to form 2,2′-(ethylenedioxy)bis (Ethylamine) concentration is the aqueous phase of 10uL / mL;

[0039] 3) Evenly drop the above-mentioned oil phase into the above-mentioned water phase to form a water-oil uniform emulsion dispersion system, wherein the volume ratio of the oil phase and the water phase is adjusted to 1:20, and ultrasonic dispersion is performed with an ultrasonic disperser, and the ...

Embodiment example 3

[0042] Implementation Case 3: Based on the novel polymaleic anhydride-alt-1-octadecene phacoemulsification modified quantum dots.

[0043] 1) Add 1.6mg of polymaleic anhydride-alt-1-octadecene (Poly(maleic anhydride-alt-1-octadecene), PMAO) and 100uL quantum dots to the reactor (the mass fraction ratio is 200:1 ), then add 800uL methylene chloride to the reactor to form the oil phase that polymaleic anhydride-alt-1-octadecene concentration is 2mg / mL;

[0044] 2) Add 160uL ring-opener 2,2′-(ethylenedioxy)bis(ethylamine) to the reactor, and then add 16mL deionized water to the reactor to form 2,2′-(ethylenedioxy)bis (Ethylamine) concentration is the aqueous phase of 10uL / mL;

[0045] 3) Evenly drop the above-mentioned oil phase into the above-mentioned water phase to form a water-oil uniform emulsion dispersion system, wherein the volume ratio of the oil phase and the water phase is adjusted to 1:20, and ultrasonic dispersion is performed with an ultrasonic disperser, and the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com