Method for characterizing Curie temperature of barium strontium titanate ceramic based on up-conversion luminescence

A technology of Curie temperature and barium strontium titanate, which is applied in the field of preparation of rare earth-doped barium strontium titanate ceramics, can solve problems such as sample damage and strict shape requirements, and achieve good stability, high test accuracy, and phonon The effect of low energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Embodiment 1: The method for characterizing the Curie temperature of barium strontium titanate ceramics based on up-conversion luminescence in this embodiment is implemented according to the following steps:

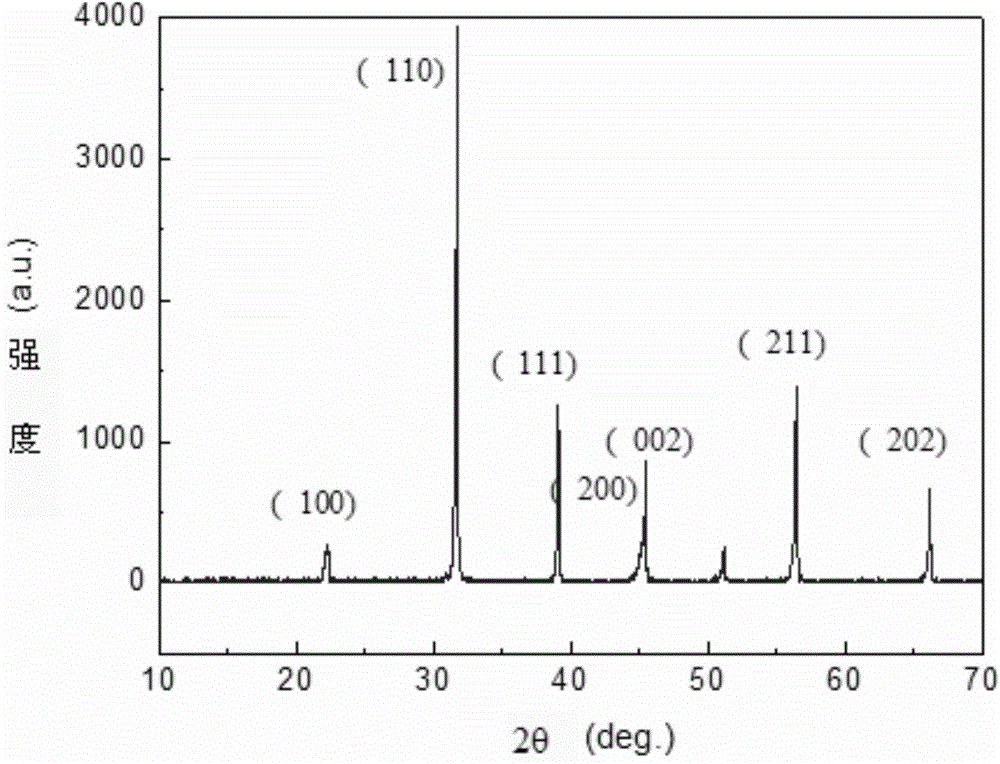

[0019] 1. According to the chemical formula Ba 0.8 Sr 0.2 TiO 3 Put BaCO 3 , SrCO 3 and TiO 2 The powders are mixed evenly to obtain BST powder, the rare earth inorganic salt is dissolved in anhydrous ethanol to obtain a rare earth inorganic salt solution, and then the BST powder and the rare earth inorganic salt solution are added to the ball milling tank for ball milling, and the mixture after ball milling is subjected to After drying, the temperature is kept at 1100-1300° C. for 4-6 hours to obtain rare earth doped BST powder;

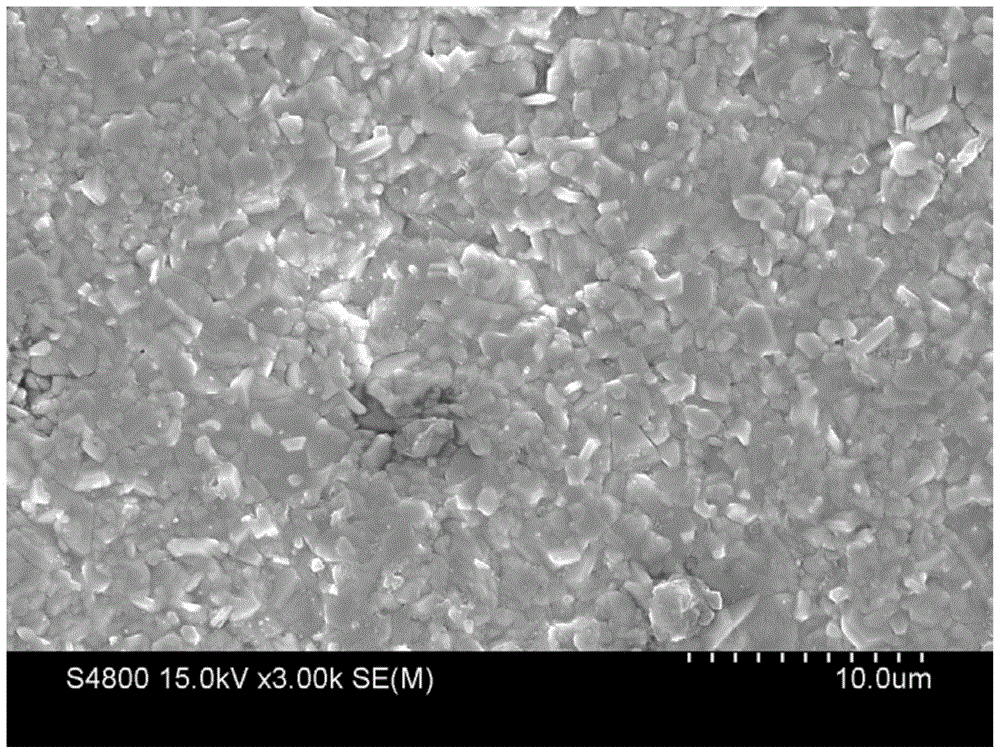

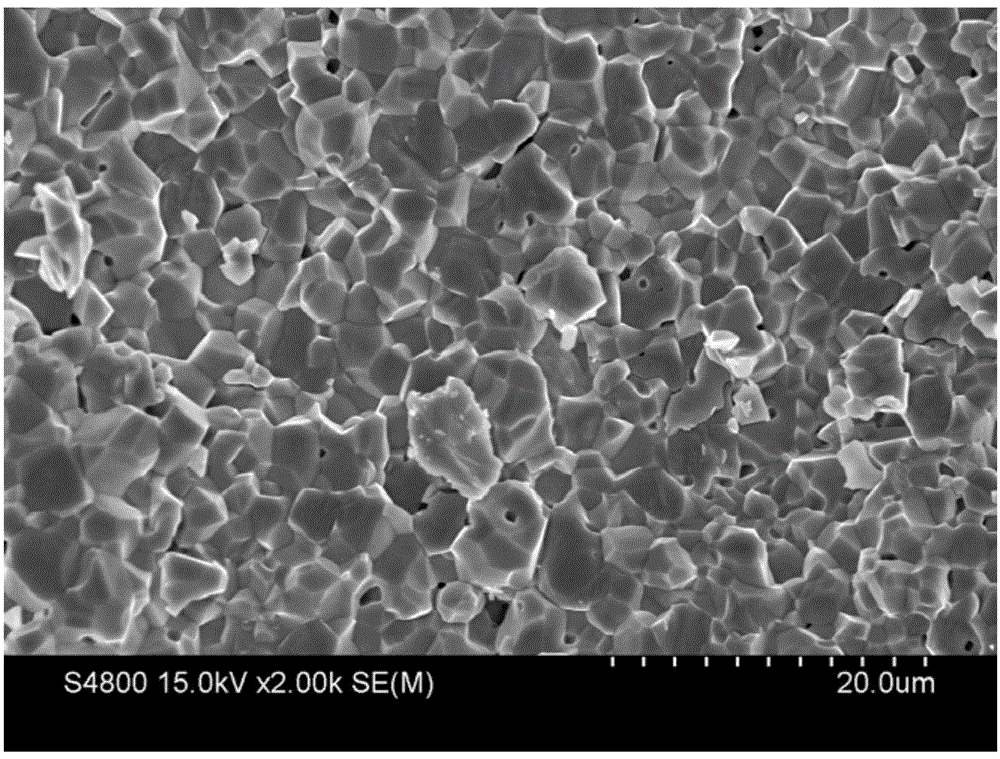

[0020] 2. Grind the rare earth-doped BST powder obtained in step 1, add a binder to granulate twice after sieving, and then place it in a mold to dry-press the granulated powder at room temperature and under a pressure of 10 MPa T...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the rare earth inorganic salt described in Step 1 is Er(NO3 ) 3 ·6H 2 O, Yb(NO 3 ) 3 ·6H 2 O or Tm(NO 3 ) 3 ·6H 2 One or a mixture of O. Other steps and parameters are the same as those in Embodiment 1.

[0029] This embodiment Er 3+ The doping concentration of ions is 0.5% ~ 7% mol, Yb 3+ The doping concentration of ions is 2% ~ 15% mol, Tm 3+ The doping concentration of ions is 0.2%-0.8% mol.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, BST powder and rare earth inorganic salt solution are added to a ball mill tank and ball milled at a speed of 300-400 r / min for 5-7 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com