Nanometer gold spherical shell photosensitive liposome and preparation method for same

A liposome and nano-gold technology, which is applied in liposome delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems that are difficult to act on deep tissue sites, side effects of cells and tissues, and dependence on ultraviolet light irradiation, etc. problems, to achieve the best light-to-heat conversion performance, easy control of the reaction, and the effect of improving tissue penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

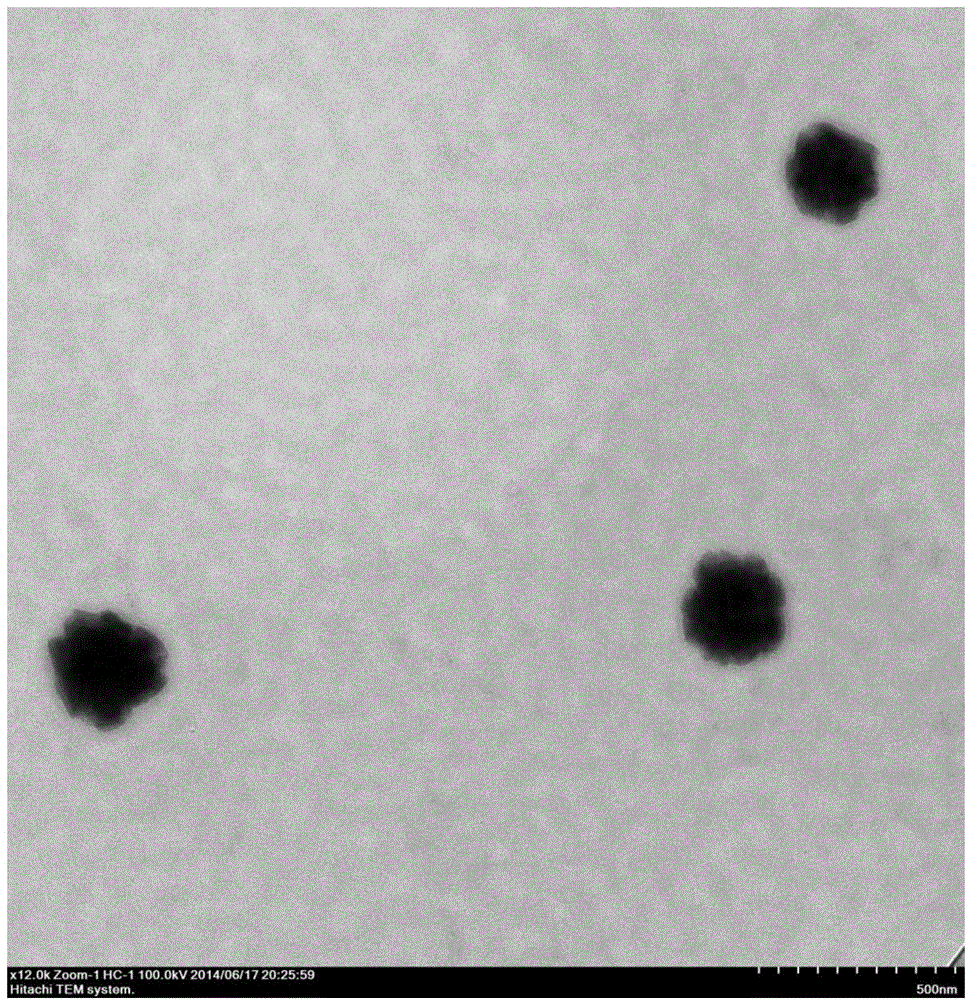

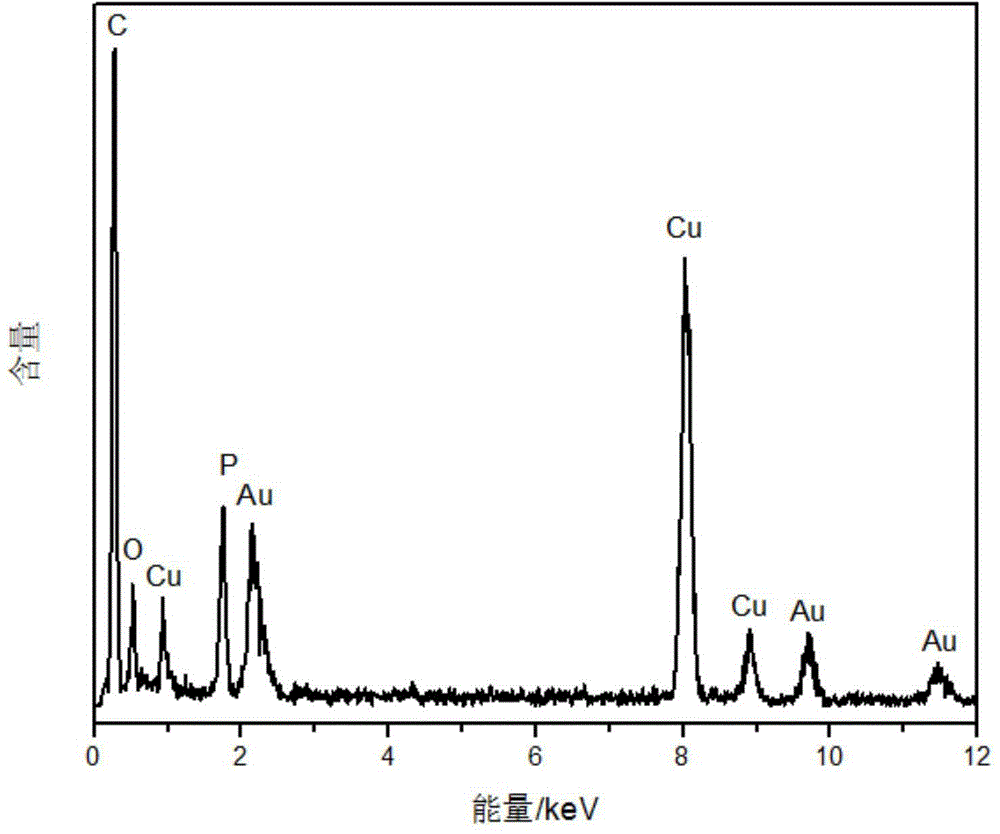

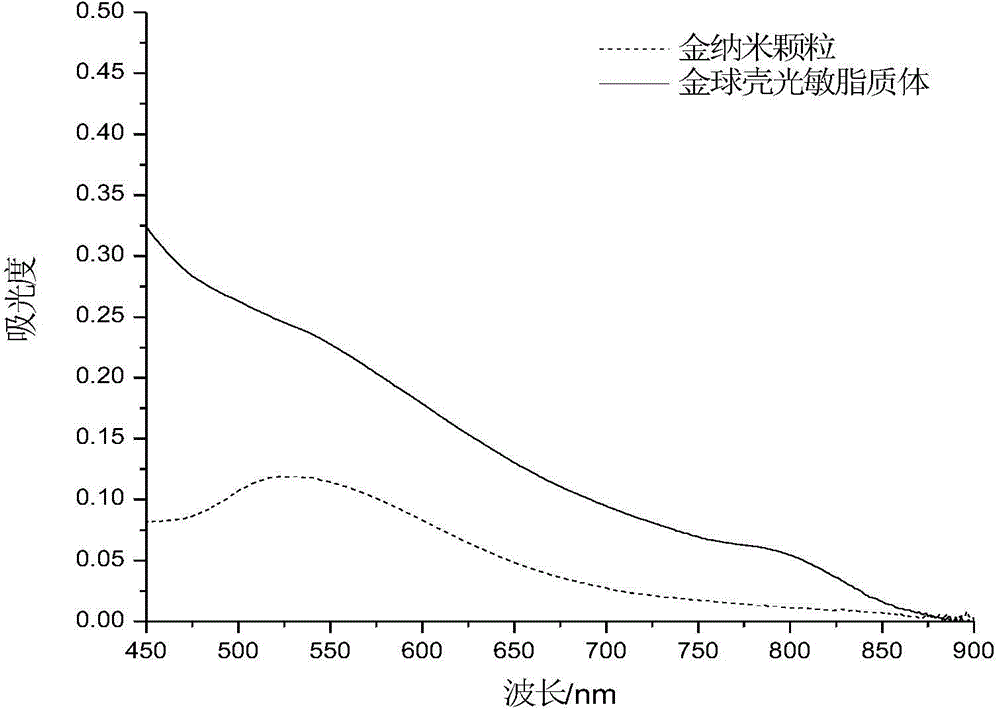

Image

Examples

Embodiment 1

[0025] 1 mg wedelolide (purchased from Shanghai Zhanshu Chemical Technology Co., Ltd.), 55 mg soybean lecithin (purchased from Shenyang Tianfeng Biopharmaceutical Co., Ltd.) and 5 mg cholesterol (purchased from Tianjin Damao Chemical Instrument Supply Station) were dissolved in In 4mL absolute ethanol, a homogeneous oil phase, ie lipid ethanol solution, was obtained by magnetic stirring. The liposome ethanol solution was dropped dropwise into 10mL ultrapure water at 37°C, and a magnetic stirrer was used to stir slowly throughout the dropping process to obtain a liposome suspension. By means of rotary evaporation or magnetic stirring, at 25° C., the absolute ethanol in the liposome suspension was removed at a uniform speed and slowly to obtain a wedelide nanoliposome solution.

[0026] The configuration concentration is the cysteine hydrochloride solution of 0.5 mg / mL, and 2 mL of the wedelia lactone nanoliposome solution obtained before is added dropwise in 1 mL of cysteine ...

Embodiment 2

[0031] 1 mg wedelolide (purchased from Shanghai Zhanshu Chemical Technology Co., Ltd.), 60 mg soybean lecithin (purchased from Shenyang Tianfeng Biopharmaceutical Co., Ltd.) and 6 mg cholesterol (purchased from Tianjin Damao Chemical Instrument Supply Station) were dissolved in In 4mL absolute ethanol, a homogeneous oil phase, ie lipid ethanol solution, was obtained by magnetic stirring. Take 2mL lipid ethanol solution and drop it into 10mL ultrapure water at 40°C. During the dropping process, a magnetic stirrer is used to stir slowly throughout the whole process to obtain a liposome suspension. By means of rotary evaporation or magnetic stirring, at 28° C., the absolute ethanol in the liposome suspension was removed at a uniform speed and slowly to obtain a wedelide nanoliposome solution.

[0032] The cysteine hydrochloride solution with a concentration of 1.0 mg / mL is configured, and 2 mL of the previously obtained wedelolactone nanoliposome solution is added dropwise to 1...

Embodiment 3

[0037] 1 mg wedelolide (purchased from Shanghai Zhanshu Chemical Technology Co., Ltd.), 65 mg soybean lecithin (purchased from Shenyang Tianfeng Biopharmaceutical Co., Ltd.) and 6 mg cholesterol (purchased from Tianjin Damao Chemical Instrument Supply Station) were dissolved in In 4mL absolute ethanol, a homogeneous oil phase, ie lipid ethanol solution, was obtained by magnetic stirring. Take 3mL lipid ethanol solution and drop it into 10mL ultrapure water at 43°C. During the dropping process, a magnetic stirrer is used to stir slowly throughout the whole process to obtain a liposome suspension. By means of rotary evaporation or magnetic stirring, the absolute ethanol in the liposome suspension was removed at a uniform speed and slowly at 30° C. to obtain a wedelide nanoliposome solution.

[0038] The cysteine hydrochloride solution with a concentration of 2.0 mg / mL is configured, and 2 mL of the previously obtained wedelolactone nanoliposome solution is added dropwise to 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com