Oily soil degradation method based on combination of pseudomonas, zoogloea and electric field

A technology of Pseudomonas and Pseudomonas genus, applied in the restoration of contaminated soil, etc., can solve the problem of lack of high added value, and achieve the effect of cost saving, cost reduction and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] According to the volume ratio of 1:1, take Pseudomonas and Kineticum respectively; put the weighed Pseudomonas and Kineticum into two fermentation tanks for sealed fermentation, and the fermentation time is 45h; Mix the fermented Pseudomonas and Kinetoglia to form a mixed bacterial solution; weigh ammonium nitrate NH 4 NO 3 , Potassium dihydrogen phosphate KH 2 PO 4 , and the weighed ammonium nitrate NH 4 NO 3 , Potassium dihydrogen phosphate KH 2 PO 4 Add together in the mixed bacterial solution to prepare the bacterial agent for treating oily soil, wherein 0.032g of ammonium nitrate and 0.004g of potassium dihydrogen phosphate will be added to each liter of mixed bacterial solution;

[0065] The oily soil to be treated and sawdust were weighed respectively according to the mass ratio of 27:1; the oil content in the oily soil to be treated was 3%; the oily soil to be treated was mixed with sawdust, and the Mix the oily soil to be treated with sawdust evenly to c...

Embodiment 2

[0072] According to the volume ratio of 1.5:1, respectively take Pseudomonas and Kineticum; put the weighed Pseudomonas and Kineticum into two fermentation tanks for sealed fermentation, and the fermentation time is 46h; Mix the fermented Pseudomonas and Kinetoglia to form a mixed bacterial solution; weigh ammonium nitrate NH 4 NO 3 , Potassium dihydrogen phosphate KH 2 PO 4 , and the weighed ammonium nitrate NH 4 NO 3 , Potassium dihydrogen phosphate KH 2 PO 4 Add together in the mixed bacterial solution to prepare the bacterial agent for treating oily soil, wherein 0.032g of ammonium nitrate and 0.004g of potassium dihydrogen phosphate will be added to each liter of mixed bacterial solution;

[0073] The oily soil to be treated and sawdust were weighed respectively according to the mass ratio of 27.5:1; wherein the oil content in the oily soil to be treated was 4%; the oily soil to be weighed was mixed with sawdust and stirred to The oily soil to be treated is evenly ...

Embodiment 3

[0080] According to the volume ratio of 2:1, Pseudomonas and Kinetoglobulin were respectively taken; the weighed Pseudomonas and Kinetoglobulin were respectively put into two fermentation tanks for sealed fermentation, and the fermentation time was 47h; Mix the fermented Pseudomonas and Kinetoglia to form a mixed bacterial solution; weigh ammonium nitrate NH 4 NO 3 , Potassium dihydrogen phosphate KH 2 PO 4 , and the weighed ammonium nitrate NH 4 NO 3 , Potassium dihydrogen phosphate KH 2 PO 4 Add together in the mixed bacterial solution to prepare the bacterial agent for treating oily soil, wherein 0.032g of ammonium nitrate and 0.004g of potassium dihydrogen phosphate will be added to each liter of mixed bacterial solution;

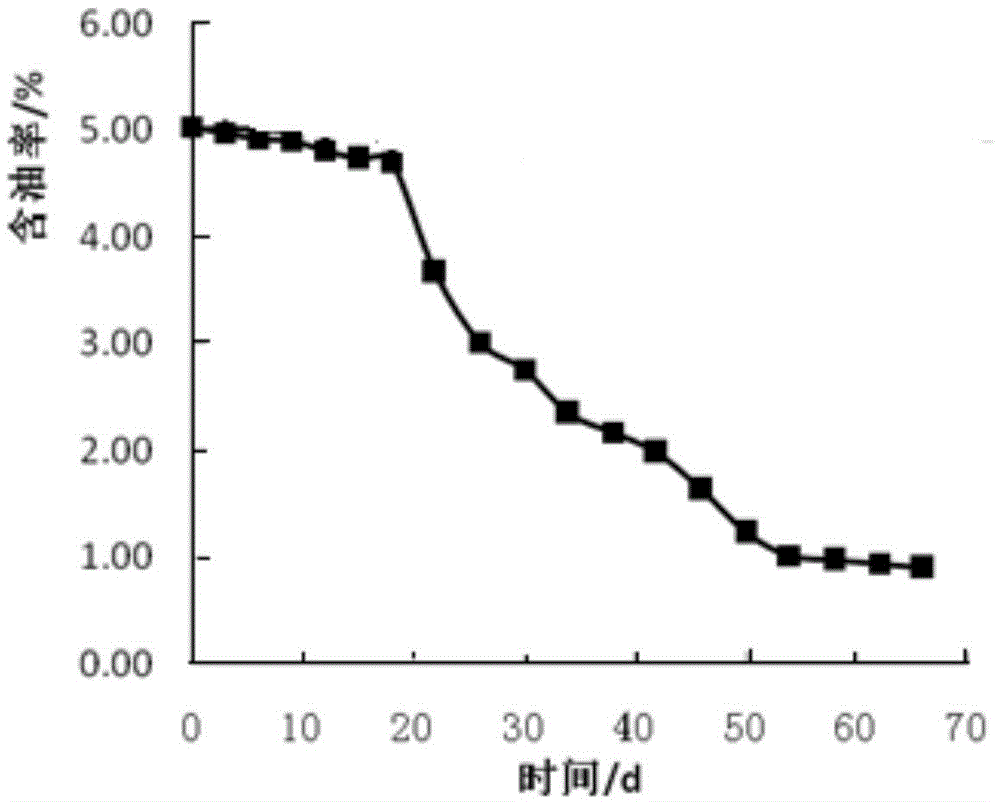

[0081] The oily soil to be treated and sawdust were weighed respectively according to the mass ratio of 28:1; the oil content in the oily soil to be treated was 5%; the oily soil to be treated was mixed with sawdust, and the The oily soil to be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com