Production method of non-sintered artificial pelelith

A production method and volcanic stone technology are applied in the field of production of sinter-free artificial volcanic stone, which can solve the problem that the sinter-free artificial volcanic stone has no patent application or literature report, and achieves easy large-scale production, wide application and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

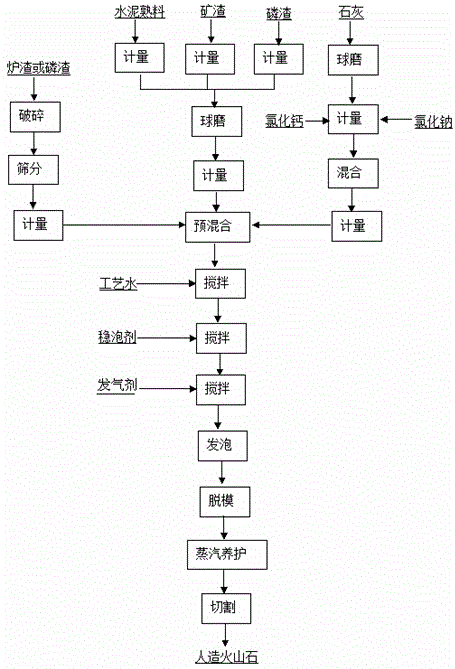

Image

Examples

Embodiment 1

[0058] Embodiment 1: the production method of this sinter-free artificial volcanic stone, content is as follows:

[0059] 1. Formula composition

[0060] (1) Composite cementing material: 60kg of cement clinker, 30kg of slag, and 10kg of phosphorus slag. After mixing, ball mill until the particle size exceeds 200 mesh square hole sieve and the sieve balance is less than 5%. The amount of composite cementing material is 60% of the total weight of the base material. %.

[0061] (2) Reinforcement material: Crush and sieve the slag, and take particles with a particle size between 0.177 and 0.25mm. The amount of reinforcement material is 30% of the total weight of the base material.

[0062] (3) The activator is made of lime, calcium chloride, and sodium chloride. The amount of activator is 10% of the total weight of the base material, of which lime accounts for 90wt% of the total activator, and its active calcium oxide content is greater than 75%, the particle size is less than ...

Embodiment 2

[0070] Embodiment 2: the production method of this sinter-free artificial volcanic stone, content is as follows:

[0071] 1. Formula composition

[0072] (1) Composite cementing material: 50kg of clinker, 30kg of slag, and 20kg of phosphorus slag. After mixing, ball mill until the particle size exceeds 200 mesh square hole sieve and the sieve balance is less than 5%. The amount of composite cementing material is 65% of the total weight of the base material. ;

[0073] (2) Reinforcement material: crush and sieve phosphorus slag, take particles with a particle size of 0.177-0.25mm, and the amount of reinforcement material is 20% of the total weight of the base material;

[0074] (3) The activator is made of lime, calcium chloride, and sodium chloride. The amount of activator is 15% of the total weight of the base material, of which lime accounts for 95wt% of the total activator, and its active calcium oxide content is greater than 75%, the particle size is less than 10% after...

Embodiment 3

[0082] Embodiment 3: the production method of this sinter-free artificial volcanic stone, content is as follows:

[0083] 1. Formula composition

[0084] (1) Composite cementing material: 55 kg of clinker, 25 kg of slag, and 20 kg of phosphorus slag. After mixing, ball mill until the particle size exceeds 200 mesh square hole sieve and the sieve balance is less than 5%. The amount of composite cementing material is the total weight of the base material 70% of.

[0085] (2) Reinforcement material: Crush and sieve the slag, and take particles with a particle size between 0.177 and 0.25mm. The amount of reinforcement material is 20% of the total weight of the base material.

[0086] (3) The activator is made of lime, calcium chloride, and sodium chloride. The amount of activator is 10% of the total weight of the base material, of which lime accounts for 93wt% of the total activator, and its active calcium oxide content is greater than 75%, the particle size is less than 10% af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com