Preparation method of PHBV composite film for packaging material

A packaging material and composite film technology, applied in the field of packaging materials, can solve problems such as narrowing the application range, unsatisfactory heat resistance and toughness, etc., and achieve improved heat distortion temperature and heat resistance, good heat resistance, and good heat resistance Effects on Sexuality and Mechanical Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

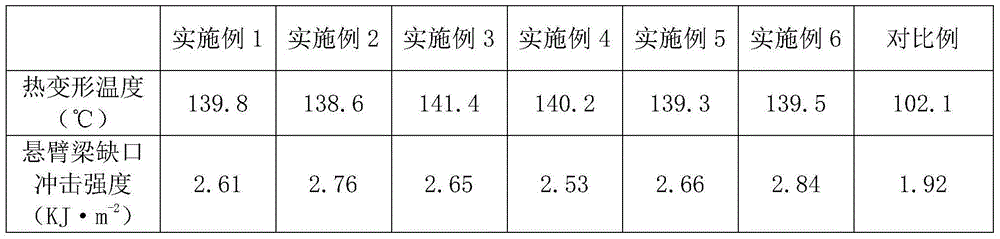

Examples

Embodiment 1

[0024] A preparation method of PHBV composite film for packaging materials, comprising the following steps:

[0025] (1) Superfinely pulverize the serpentine with a ball mill to obtain a serpentine powder with a particle size of 3 μm, dissolve sodium stearate in deionized water and mix evenly to obtain a modified liquid, and the serpentine powder The weight ratio to sodium stearate is 20:1, add the serpentine powder to the modification solution, put it in a constant temperature water bath with a temperature of 80°C and stir for 30 minutes, take it out, filter it, and place it in a drying oven with a temperature of 80°C. Dried to constant weight in the box to obtain modified serpentine powder;

[0026] (2) Add 85 parts by weight of PHBV into a twin-roller masticator for 2 minutes at 140°C, and add 5 parts by weight of modified serpentine powder and 4 parts by weight of epoxidized soybean oil into the twin-roller masticator in turn Continue to plasticize for 8 minutes, thin pas...

Embodiment 2

[0029] A preparation method of PHBV composite film for packaging materials, comprising the following steps:

[0030] (1) Superfinely pulverize the serpentine with a ball mill to obtain a serpentine powder with a particle size of 3 μm, dissolve sodium stearate in deionized water and mix evenly to obtain a modified liquid, and the serpentine powder The weight ratio to sodium stearate is 20:1, add the serpentine powder to the modification solution, put it in a constant temperature water bath with a temperature of 80°C and stir for 30 minutes, take it out, filter it, and place it in a drying oven with a temperature of 80°C. Dried to constant weight in the box to obtain modified serpentine powder;

[0031] (2) Add 88 parts by weight of PHBV into the double-roller masticator and plasticize for 2 minutes at 140°C, add 2.5 parts by weight of modified serpentine powder and 4 parts by weight of epoxy soybean oil into the double-roller masticator Continue to plasticize for 8 minutes, th...

Embodiment 3

[0034] A preparation method of PHBV composite film for packaging materials, comprising the following steps:

[0035] (1) Superfinely pulverize the serpentine with a ball mill to obtain a serpentine powder with a particle size of 3 μm, dissolve sodium stearate in deionized water and mix evenly to obtain a modified liquid, and the serpentine powder The weight ratio to sodium stearate is 20:1, add the serpentine powder to the modification solution, put it in a constant temperature water bath with a temperature of 80°C and stir for 30 minutes, take it out, filter it, and place it in a drying oven with a temperature of 80°C. Dried to constant weight in the box to obtain modified serpentine powder;

[0036] (2) Add 84 parts by weight of PHBV into the double-roller masticator at 140°C for plasticization for 2 minutes, and add 4 parts by weight of modified serpentine powder and 4 parts by weight of epoxy soybean oil into the double-roller masticator in turn Continue to plasticize for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com