Building internal wall coating

A technology for building interior and coatings, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of not being able to improve the indoor environment, achieve indoor air improvement, excellent photocatalytic performance, and enhance energy saving efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

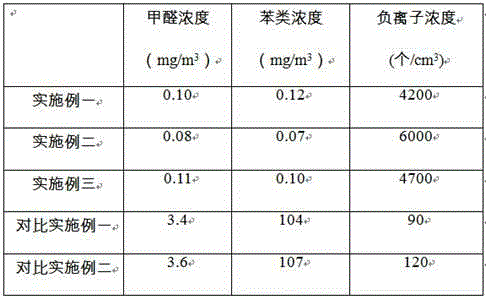

Examples

Embodiment 1

[0057] Prepare paint as follows:

[0058] (1) crushing and grinding the adsorbent, and screening to obtain adsorbent particles with a particle size of 0.1-10 microns;

[0059] (2) Mix 1 part of the adsorbent particles described in (1) with 20 parts of titanium dioxide nanopowder according to the required mass fraction;

[0060] (3) Under the condition of less than 500r / min, mix 0.2 part of dispersant, 0.1 part of defoamer and 0.1 part of wetting agent evenly;

[0061] (4) Under the condition of 500-1000r / min, add 21 parts of the mixture of adsorbent particles and titanium dioxide nanopowder, 20 parts of filler, 5 parts of air microcapsules and plant fiber to the above-mentioned dispersant, defoamer and wetting agent mixture 1 part and mix well;

[0062] (5) Under the condition of less than 500r / min, add 40 parts of aqueous emulsion, 6 parts of putty, 3 parts of modified floating beads and 1 part of film-forming aid to the mixture (4) and mix well.

[0063] The putty formula...

Embodiment 2

[0079] Prepare paint as follows:

[0080] (1) crushing and grinding the adsorbent, and screening to obtain adsorbent particles with a particle size of 0.1-10 microns;

[0081] (2) Mix 5 parts of the adsorbent particles described in (1) with 25 parts of titanium dioxide nanopowder according to the required mass fraction;

[0082] (3) Under the condition of less than 500r / min, mix 0.5 part of dispersant, 0.2 part of defoamer and 0.1 part of wetting agent evenly;

[0083] (4) Under the condition of 500-1000r / min, add 21 parts of the mixture of adsorbent particles and titanium dioxide nanopowder, 15 parts of filler, 15 parts of air microcapsules and plant fiber to the above-mentioned dispersant, defoamer and wetting agent mixture 5 parts and mix well;

[0084] (5) Under the condition of less than 500r / min, add 60 parts of aqueous emulsion, 7 parts of putty, 5 parts of modified bleaching beads and 2.5 parts of film-forming aid to the mixture (4) and mix well.

[0085] The putty ...

Embodiment 3

[0101] (1) crushing and grinding the adsorbent, and screening to obtain adsorbent particles with a particle size of 0.1-10 microns;

[0102] (2) Mix 2.5 parts of the adsorbent particles described in (1) with 30 parts of titanium dioxide nanopowder according to the required mass fraction;

[0103] (3) Under the condition of less than 500r / min, mix 0.8 part of dispersant, 0.2 part of defoamer and 0.2 part of wetting agent evenly;

[0104] (4) Under the condition of 500-1000r / min, add 32.5 parts of the mixture of adsorbent particles and titanium dioxide nanopowder, 20 parts of filler, 25 parts of air microcapsules and plant fiber to the above-mentioned mixture of dispersant, defoamer and wetting agent 3 parts and mix well;

[0105] (5) Under the condition of less than 500r / min, add 60 parts of aqueous emulsion, 9 parts of putty, 3 parts of modified floating beads and 5 parts of film-forming aid to the mixture (4) and mix well.

[0106] The putty formula is the same as the putty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com