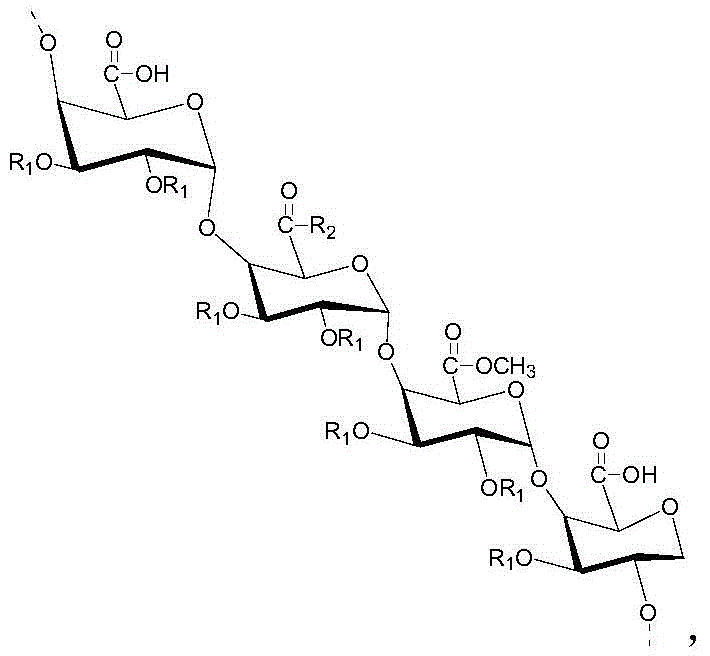

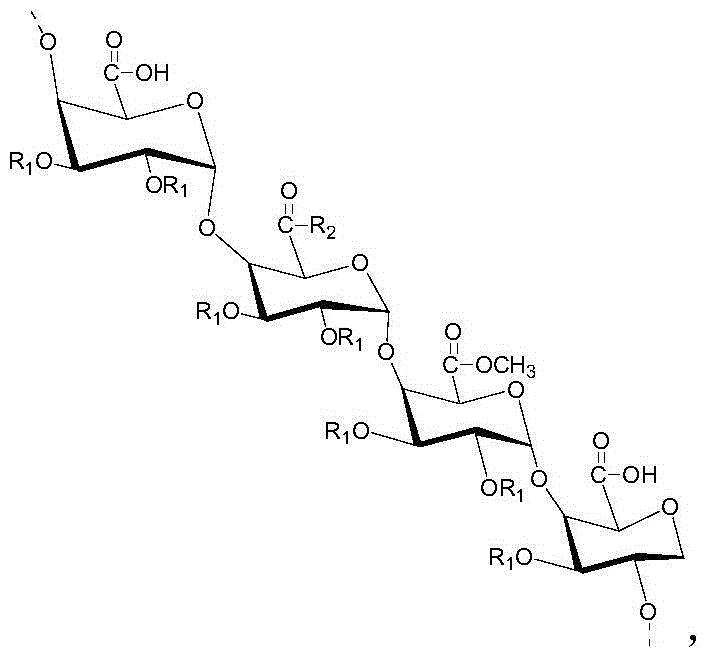

Environment-friendly composite hydrate inhibitor and preparation method thereof

A hydrate inhibitor, a composite technology, which is applied to drilling compositions, chemical instruments and methods, mechanical equipment, etc., can solve the problems of poor biodegradability, low inhibitory activity, and high synthesis cost, and achieve low production costs. , Overcome the effects of high toxicity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Extraction of Pectin from Pomelo Peel

[0040] Step 1: Peel fresh Shatian pomelo from Meizhou City, Guangdong Province to obtain 130g of fresh pomelo peel. Mince 130g of fresh pomelo peel into small cubes of 0.5cm×0.5cm×0.5cm, and put the treated small pieces of pomelo peel into a 500ml one-necked flask. Boil in hot water at 90°C for 10 minutes to inactivate the pectinase in pomelo peel. Rinse the boiled pomelo peel 3 times until the solution is colorless to ensure that the pigment in the pomelo peel is removed.

[0041] Step 2: Prepare a solution with a pH of 2.0, and extract for 45-60 minutes under the conditions of a solid-to-liquid ratio (volume ratio) of pomelo peel and solution of 1:10 and a temperature of 95°C.

[0042] Step 3: Filter the solution obtained in step 2 with a Buchner funnel at 50° C. to obtain a filtrate.

[0043] Step 4: 95% alcohol is added to the filtrate obtained in step 3. With the gradual addition of alcohol (the volume ratio of alcohol to ...

Embodiment 2

[0052] Before the reaction started, the reactor was cleaned with deionized water, and 60 g of deionized water was added. After the temperature in the reactor was stabilized at 30° C., 10.5 MPa of simulated natural gas (CH 4 87.16%, C 2 h 6 3.60%, C 3 h 8 1.43%, i-C 4 h 10 0.29%, n-C 4 h 10 0.30%, i-C 5 h 12 0.10%, n-C 5 h 12 0.03%, C 6 h 14 0.95%, CO 2 5.73%, N 2 0.41%), turn on the magnetic stirring (700rpm). After the equilibrium pressure of the dissolved gas in the kettle is stabilized (stabilized at 10.2MPa), the temperature is lowered, the temperature of the box is set to 0.5°C, and the data acquisition system is turned on. After 2 hours, the temperatures of the six autoclaves were all stable at around 2.0°C. Through the temperature and pressure signals recorded by data collection, it was found that the temperature of the six kettles suddenly rose and the pressure dropped significantly at 1.1h, 0.9h, 1.2h, 0.98h, 1.14h, and 1.21h, which shows that the six ...

Embodiment 3

[0058] Before the reaction starts, the reactor is cleaned with deionized water, and 48g of deionized water and 12g of crude oil samples are added (the water content of the system is 80%). After the temperature in the reactor is stabilized at 30°C, 10.5MPa of simulated natural gas ( CH 4 87.16%, C 2 h 6 3.60%, C 3 h 8 1.43%, i-C 4 h 10 0.29%, n-C 4 h 10 0.30%, i-C 5 h 12 0.10%, n-C 5 h 12 0.03%, C 6 h 14 0.95%, CO 2 5.73%, N 2 0.41%), turn on the magnetic stirring (700rpm). After the equilibrium pressure of the dissolved gas in the kettle is stabilized (stabilized at 10.2MPa), the temperature is lowered, the temperature of the box is set to 0.5°C, and the data acquisition system is turned on. After 2 hours, the temperatures of the six autoclaves were all stable at around 2.0°C. Through the temperature and pressure signals recorded by data collection, it was found that the temperature suddenly rose and the pressure dropped significantly in the 6 kettles at 1.5h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com