Method and equipment for adopting variable-frequency alternating current electric field for assisting freeze drying of drug liposome powder

一种交流电场、脂质体粉的技术,应用在脂质体输送、照明和加热设备、冻干输送等方向,能够解决品质均匀性得不到保证、干燥时间长、冷冻时间长等问题,达到避免灭菌处理工作、干燥升华阶段减短、冷冻结晶时间减少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

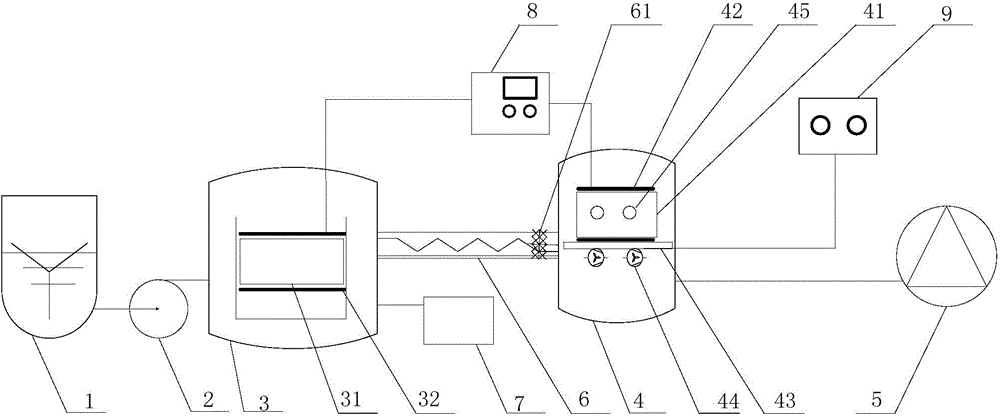

[0042] figure 1 It is a schematic diagram of the equipment for assisted freeze-drying of drug liposome powder by frequency-variable alternating electric field in this embodiment. figure 1 As shown, it includes a preparation tank 1, a metering pump 2, a dehydrator 3, and a high / low temperature treatment chamber 4 connected in sequence; an electrode plate 32 is respectively arranged on the upper and lower sides of the sample tank 31 in the dehydrator 3; An electrode plate 42 is respectively arranged above and below the sample tank 41 in the high / low temperature processing chamber 4; the electrode plate is connected with the high-voltage frequency conversion AC power supply control box 8; the high / low temperature processing chamber 4 is also connected with a vacuum pump 5 connection; the high / low temperature processing chamber is used for freeze-drying and heating-drying of samples.

[0043]The sample tank 41 of the high / low temperature processing chamber 4 is provided with a se...

Embodiment 2

[0048] The method for the assisted freeze-drying of drug liposome powder of the frequency conversion alternating electric field of the present embodiment may further comprise the steps:

[0049] Weigh a certain amount of breviscapine, egg yolk lecithin, cholesterol, surfactant, and stabilizer in appropriate amounts, add a small amount of ethanol to ultrasonic to dissolve, decompress and rotary evaporate until the ethanol evaporates to dryness, and use a hydration medium containing mannitol and antioxidants Hydrate to obtain scutellarin liposome suspension (water content is 55%), the total volume is 3L. Flow into the sample tank of the dehydrator through the metering pump, give 4kV, 1kHz high-voltage alternating current treatment for 8min (at this time, the alternating current pulse occupies 40%), and demulsify and dehydrate to the water content of 25%; when preparing scutellarin liposome suspension At the same time, turn on the semiconductor power supply control box, directly ...

Embodiment 3

[0051] Weigh a certain amount of docetaxel, appropriate amount of soybean lecithin, cholesterol, surfactant, and mannitol, add a small amount of ethanol and sonicate until dissolved, reduce pressure and rotary evaporate until the ethanol evaporates to dryness, and use a hydration medium containing mannitol and antioxidants Hydrate to obtain a docetaxel liposome suspension (with a water content of 40%), with a total volume of 4 L. Place in the sample tank of the dehydrator, give 5kV, 500Hz high-voltage alternating current treatment 10min (at this time, the alternating current pulse is 50% empty), demulsification and dehydration to water content 18%; in the preparation of docetaxel liposome suspension At the same time, turn on the semiconductor power supply control box, directly connected to the refrigeration control system, and set the temperature at -30°C; the dehydrated sample flows into the sample tank of the high / low temperature processing room through the pipeline pump (the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com