Temperature-resistant and salt-resistant jelly dispersion nitrogen foam composite control and flooding system and its preparation method

A jelly dispersion, nitrogen foam technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of affecting the stability of the gel foam system, easily changing surface properties, limited foam stabilization ability, and the like, To achieve the effect of improving the regulation and driving effect, increasing the sweep volume and maintaining the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

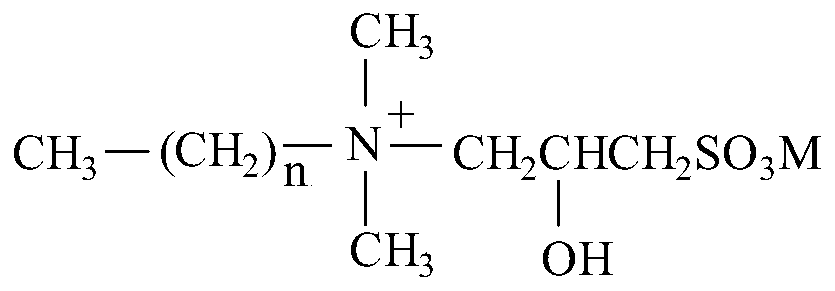

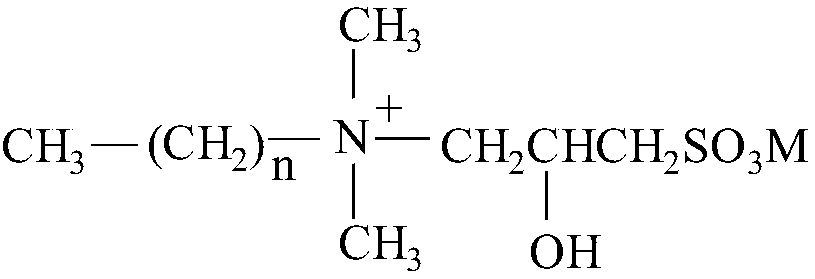

[0026] The temperature-resistant and salt-resistant jelly dispersion nitrogen foam compound control and flooding system includes: gas phase and liquid phase, the gas phase is nitrogen, and the liquid phase is foaming agent, foam stabilizer and liquid mixing water, of which: the gas-liquid phase of the gas phase and the liquid phase The ratio is controlled at 3:1, and the gas-liquid ratio is the ratio of nitrogen volume to liquid phase volume.

[0027] The liquid phase comprises: the mass fraction of the betaine type amphoteric surfactant foaming agent in the total liquid phase is 0.3%; the mass fraction of the phenolic resin jelly dispersion foam stabilizer in the liquid phase total mass is 0.1%; The amount is that the mass fraction of dosing water in the total mass of the liquid phase is 99.6%, and the sum of the mass fractions of each component is 100%.

[0028] Preparation method of phenolic resin jelly dispersion: at room temperature (20±5°C), add 0.2g of polymer to 98.9g ...

Embodiment 2

[0032] The temperature-resistant and salt-resistant jelly dispersion nitrogen foam composite flood control system includes: gas phase and liquid phase, the gas phase is nitrogen, and the liquid phase is betaine-type amphoteric surfactant foaming agent, phenolic resin jelly dispersion foam stabilizer and Mix liquid water, wherein: the gas-liquid ratio of the gas phase and the liquid phase is controlled at 5:1, and the gas-liquid ratio is the ratio of the volume of nitrogen gas to the volume of the liquid phase.

[0033] The liquid phase comprises: the mass fraction of the betaine type amphoteric surfactant foaming agent in the total liquid phase is 0.2%; the mass fraction of the phenolic resin jelly dispersion foam stabilizer in the liquid phase total mass is 0.05%; The amount is that the mass fraction of the dosing water in the total mass of the liquid phase is 99.75%, and the sum of the mass fractions of each component is 100%.

[0034] Preparation method of phenolic resin je...

Embodiment 3

[0038] The temperature-resistant and salt-resistant jelly dispersion nitrogen foam composite flood control system includes: gas phase and liquid phase, the gas phase is nitrogen, and the liquid phase is betaine-type amphoteric surfactant foaming agent, phenolic resin jelly dispersion foam stabilizer and Mix liquid water, wherein: the gas-liquid ratio of the gas phase and the liquid phase is controlled at 4:1, and the gas-liquid ratio is the ratio of the volume of nitrogen gas to the volume of the liquid phase.

[0039] The liquid phase comprises: the mass fraction of the betaine type amphoteric surfactant foaming agent in the total liquid phase is 0.4%; the mass fraction of the phenolic resin jelly dispersion foam stabilizer in the liquid phase total mass is 0.15%; The amount is that the mass fraction of the dosing water in the total mass of the liquid phase is 99.45%, and the sum of the mass fractions of each component is 100%.

[0040] Preparation method of phenolic resin je...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com