Fe3O4-COOH magnetic nano-material modified open tubular column as well as preparation method and application thereof

A magnetic nano, fe3o4-cooh technology, applied in the field of chromatography, to achieve the effect of inhibiting adsorption, good hydrophilic performance and electrostatic effect, and improving separation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

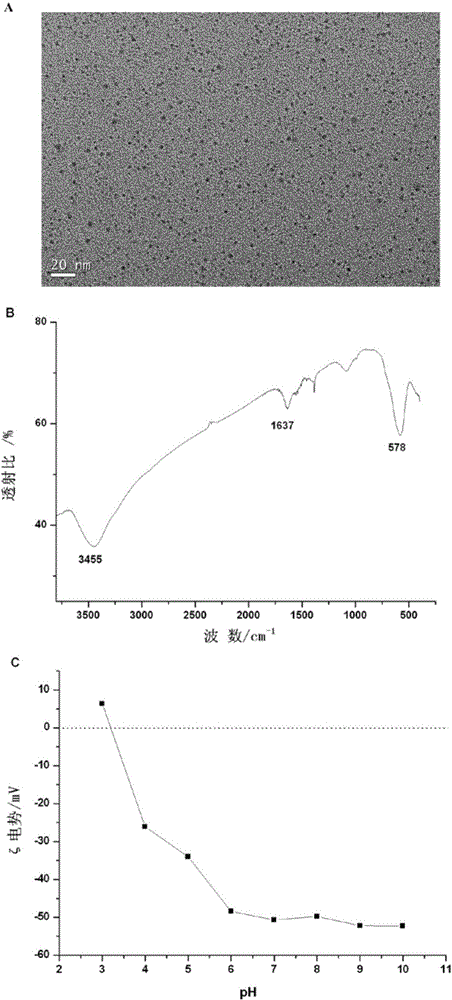

[0045] Example 1: PDDAFe 3 o 4 Preparation of -COOH MNPs open-tube column

[0046] (1) Fe 3 o 4 Preparation of -COOH MNPs: 6 mM FeCl 3 ·6H 2 O was added to 40mL of diethylene glycol for ultrasonic-assisted dissolution, then 55mM anhydrous sodium acetate and 48mM sodium acrylate were added, stirred in a constant temperature water bath at 70°C at a speed of 500r / min for 1h to form a homogeneous solution, and the solution was poured into a special Put it in a Teflon high-pressure reactor, put it in an oven, raise the temperature to 200°C, react for 10 hours, cool to room temperature, separate the product under an external magnetic field and wash it with de-ethanol and deionized water for 3 times, and dry at 50°C to obtain dispersion Uniform Fe 3 o 4 -COOH MNPs magnetic particles.

[0047] (2) Capillary pretreatment: wash 1mol / L HCl at a flow rate of 10 μL / min for 1 hour to remove organic matter on the inner surface of the capillary, deionized water for 1 hour to remove ex...

Embodiment 2

[0051] Example 2: PDDAFe 3 o 4 Preparation of -COOH MNPs open-tube column

[0052] (1) Fe 3 o 4 Preparation of -COOH MNPs: 8 mM FeCl 3 ·6H 2 O was added to 40mL of diethylene glycol for ultrasonic-assisted dissolution, then 50mM anhydrous sodium acetate and 40mM sodium acrylate were added, stirred in a constant temperature water bath at 50°C at a speed of 300r / min for 1h to form a uniform solution, and the solution was poured into a special Put it in a Teflon high-pressure reaction kettle, put it in an oven, raise the temperature to 180°C, react for 15 hours, cool to room temperature, separate the product under an external magnetic field and wash it with de-ethanol and deionized water for 3 times, and dry at 40°C to obtain the dispersion. Uniform Fe 3 o 4 -COOH MNPs magnetic particles.

[0053] (2) Capillary pretreatment: wash 1.5mol / L HCl at a flow rate of 15μL / min for 1.5h to remove organic substances on the inner surface of the capillary, deionized water for 1.5h to...

Embodiment 3

[0056] Example 3: PDDAFe 3 o 4 Preparation of -COOH MNPs open-tube column

[0057] (1) Fe 3 o 4 Preparation of -COOH MNPs: 10 mM FeCl 3 ·6H 2 O was added to 40mL of diethylene glycol for ultrasonic-assisted dissolution, then 60mM anhydrous sodium acetate and 50mM sodium acrylate were added, stirred in a constant temperature water bath at 60°C at a speed of 400r / min for 1h to form a uniform solution, and the solution was poured into a special Put it in a Teflon high-pressure reaction kettle, put it in an oven, heat up to 190°C, react for 20 hours, cool to room temperature, separate the product under an external magnetic field and wash it with de-ethanol and deionized water for 3 times, and dry at 50°C to obtain dispersion Uniform Fe 3 o 4 -COOH MNPs magnetic particles.

[0058] (2) Capillary pretreatment: Rinse 2mol / L HCl at a flow rate of 20 μL / min for 2 hours to remove organic substances on the inner surface of the capillary, deionized water for 2 hours to remove exce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com