H9 subtype avian influenza virus inactivated vaccine including chicken a-interferon protein

An avian influenza virus, interferon technology, applied in the direction of antiviral agents, peptide/protein components, medical preparations containing active ingredients, etc., can solve problems such as no reports of joint preparation of vaccines, etc. Good level and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

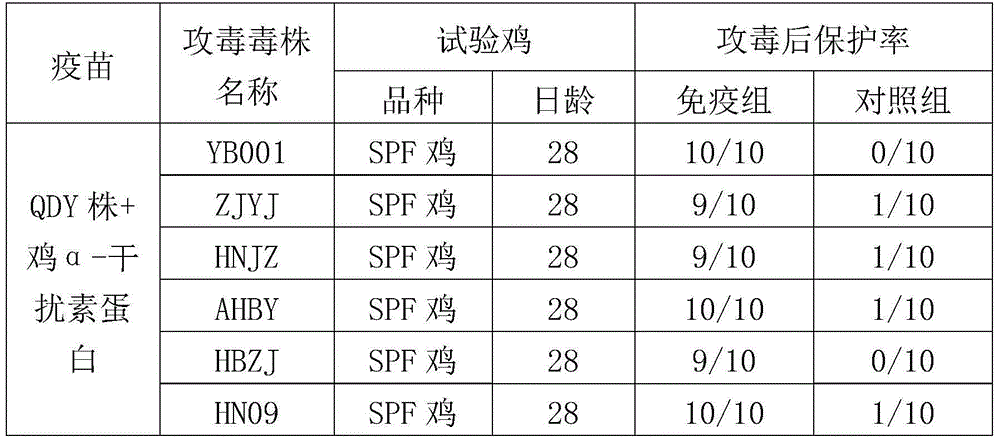

Examples

Embodiment 1

[0013] Example 1. Screening of antigenic strains for vaccine production (H9 subtype avian influenza virus QDY strain)

[0014] In 2013, the heart, spleen and other organs, throat and cloacal swabs of the diseased chickens were aseptically collected from the diseased chickens in Chengyang, Shandong Province, and ground in sterile petri dishes under aseptic conditions, and added in a ratio of 1:5. Physiological saline containing 4000 units / ml double antibody was repeatedly freeze-thawed at -20°C for 3 times. The cotton swab was directly put into the normal saline containing 10,000 units of double antibody, and it was treated at 2-8 °C for 4 hours. Both the organs and the cotton swab were centrifuged at 3500 rpm for 10 minutes. Pieces, 0.2ml / piece. The chicken embryos were incubated at 37°C, and checked once a day in the morning and evening. The dead embryos were removed in time and stored in a 4°C refrigerator. The dead embryos within 24 hours were discarded, and all the chicke...

Embodiment 2

[0018] Example 2: Preparation of antigens for seedling production

[0019] 1. Preparation of virus liquid for seedling production Inoculate 10-11-day-old SPF chicken embryos with the virus seed (QDY strain) for production through the allantoic cavity, 0.2 ml per embryo, incubate at 36 ℃ ~ 37 ℃, and illuminate the embryos twice a day, Take the chicken embryos that died after 24 hours, and harvest them at 96 hours regardless of whether they are dead or not, and cool them at 4-8°C for 12-24 hours.

[0020] 2. Preparation of chicken α-interferon protein for seedling production. The fermenter is aerated and cultured. The medium is prepared according to 70% of the volume of the fermenter, and the pH value is adjusted to 7.0-7.2 with 1 mol / L NaOH. Foaming agent. After sterilization, inoculate production strains according to 1% to 2% of the inoculum, add 10% kanamycin sulfate injection according to the proportion of 0.1% of the total volume, incubate at 36 °C, and after 2.5 hours, ta...

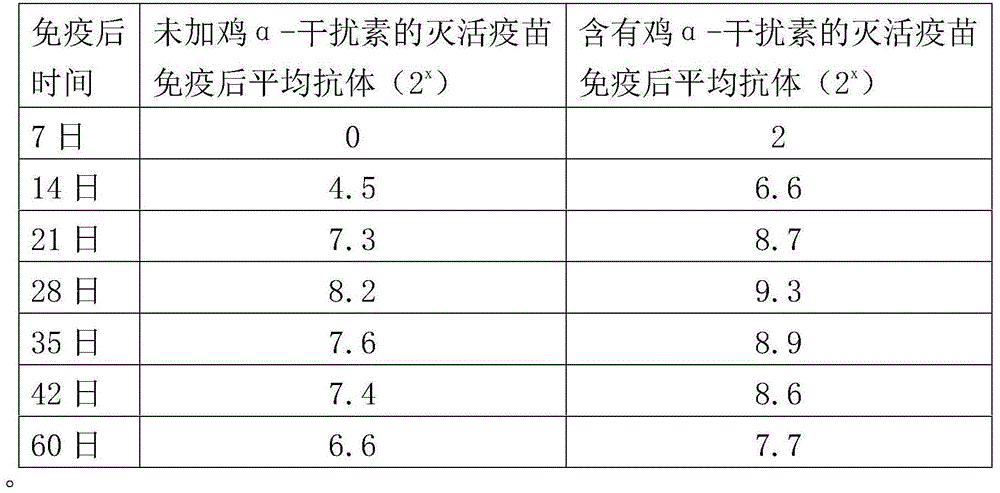

Embodiment 3

[0028] 1. Preparation of inactivated vaccine: The semi-finished antigen after passing the inspection is used for vaccine preparation (each liquid component in the following preparation is calculated by volume ratio).

[0029] (1) Preparation of oil phase Take 95 parts of veterinary white oil and 1 part of aluminum stearate, put them in an oil phase preparation tank and heat to 80°C, add 805 parts of Siben-805, until the temperature reaches 115°C, maintain 30min, set aside after cooling.

[0030] (2) Preparation of water phase: Dilute chicken α-interferon protein with normal saline to 2×10 4.0 ~2×10 6.0 Unit / 0.1ml; Dilute the inactivated H9 subtype avian influenza virus solution with physiological saline to not less than 2×10 6.0 EID 50 / 0.1ml. The chicken α-interferon protein liquid and the inactivated H9 subtype avian influenza virus liquid were respectively taken and mixed to prepare an antigen liquid for vaccine preparation. Take 5 parts of sterilized Tween-80, add it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com