A method for preparing protein hydrogel microspheres using bovine serum albumin as a base inverse microemulsion

A technology of bovine serum albumin and hydrogel microspheres, which is applied in the field of biological tissue medical material preparation, can solve the problems of organism infection, poor filling surface morphology, and the shape of hydrogel cannot meet the ideal requirements, and achieves the biological phase. Good capacitance, optimized surface morphology of material filling, and the effect of solving poor morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

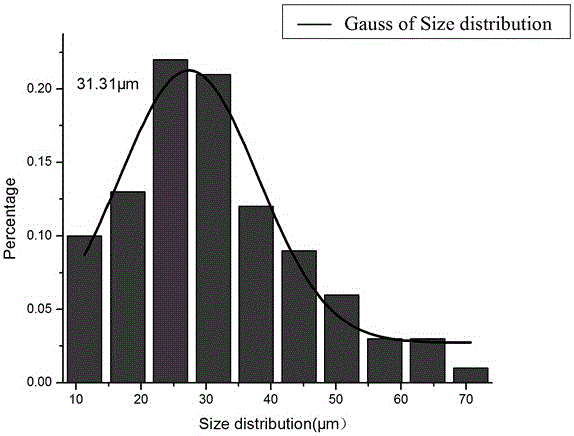

[0031] During the preparation process, 1 g of hexamethylenediamine was weighed to make 25 ml of aqueous solution, and the pH of the solution was adjusted to 6.5 with concentrated hydrochloric acid. Then slowly add the solution dropwise to 200mg of bovine serum albumin (BSA), add 100mg of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and stir for 10h. Aminated BSA is finally obtained. Then use 40ml dimethyl sulfoxide as solvent to dissolve 2g dextran, 1g p-carboxybenzaldehyde, 4-dimethylaminopyridine to form a solution, and then add 1.2g dicyclohexylcarbodiimide in the solution to start the reaction, 20 Reaction at ℃ for 18h, after post-treatment to obtain multifunctional dextran. Add 5 μl of co-emulsifier, 15 μl of 150 mg / ml Triton X-100 (emulsifier), 15 μl of aminated BSA, 15 μl of 0.05M buffer pH=7.5, 15 μl of difunctionalized dextran into the container, and then add 400 μl After the oil phase was shaken for 30 s, protein hydrogel microspheres were obta...

Embodiment 2

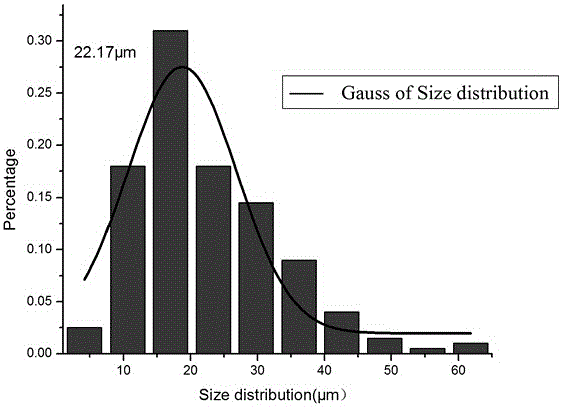

[0033] During the preparation process, 1 g of hexamethylenediamine was weighed to make 25 ml of aqueous solution, and the pH of the solution was adjusted to 6.5 with concentrated hydrochloric acid. Then slowly add the solution dropwise to 200mg of bovine serum albumin (BSA), add 100mg of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and stir for 10h. Aminated BSA is finally obtained. Then use 40ml dimethyl sulfoxide as solvent to dissolve 2g dextran, 1g p-carboxybenzaldehyde, 4-dimethylaminopyridine to form a solution, and then add 1.2g dicyclohexylcarbodiimide in the solution to start the reaction, 20 Reaction at ℃ for 18h, after post-treatment to obtain multifunctional dextran. Add 5 μl of co-emulsifier, 15 μl of 100 mg / ml Triton X-100 (emulsifier), 15 μl of aminated BSA, 15 μl of 0.05M buffer pH=7.5, 15 μl of polyfunctionalized dextran into the container, and then add 400 μl After the oil phase was shaken for 30 s, protein hydrogel microspheres were ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com