Nano photocatalytic hydrosol and preparation method thereof

A hydrosol and photocatalytic technology, applied in the field of nanomaterials, can solve the problems of inability to obtain hydrosol, inapplicability, etc., and achieve the effects of wide application range, no environmental pollution problem, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

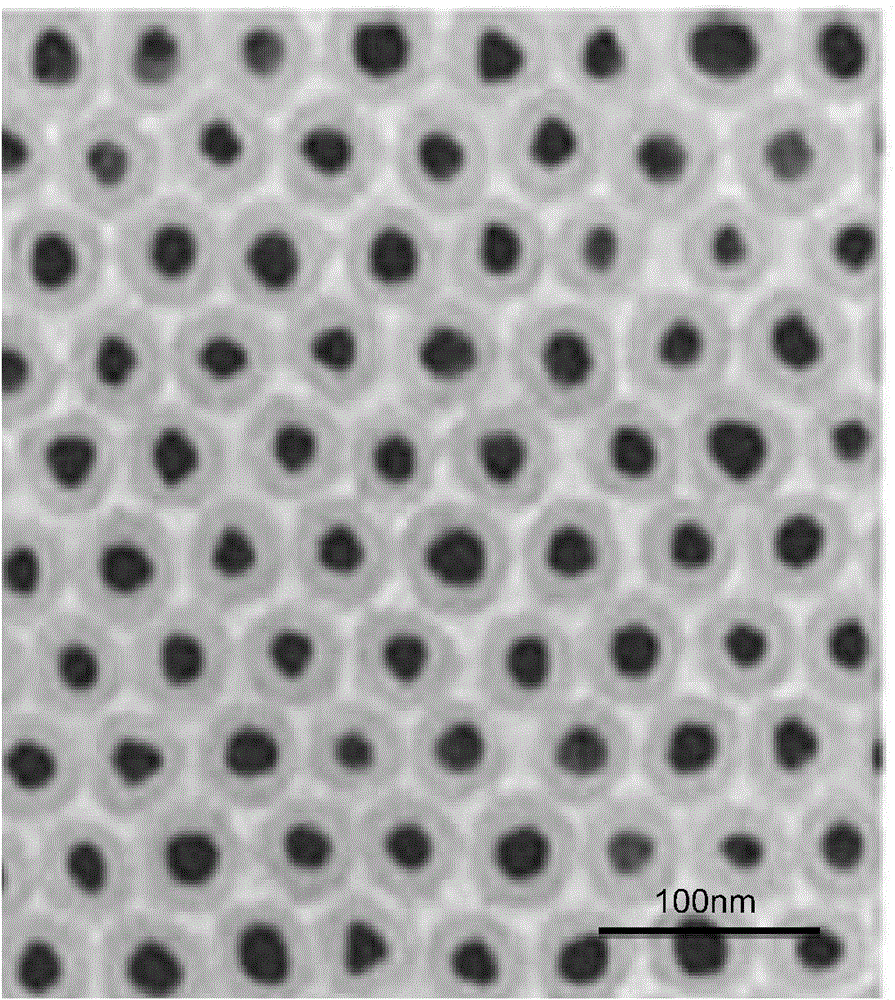

[0023] Add hydrochloric acid to 100ml of 0.04mol / L ammonium metatungstate aqueous solution to make the pH value of the solution 1, put it in a hydrothermal reaction kettle at 280°C for 15 hours, and then cool to room temperature to obtain an average particle diameter of 30nm and a pH value of 3 Nano WO 3 Water sol, heat the water sol to 80°C, add 20g of methyl titanate to make the molar ratio of Ti:W 3:1, keep the temperature for 2 hours, and cool it to room temperature to obtain a solid content of 20% and an average particle size of 50nm. The transmission electron micrographs and photoresponse curves of the hydrosol and its nanoparticles are as follows: figure 1 with4 shown.

Embodiment 2

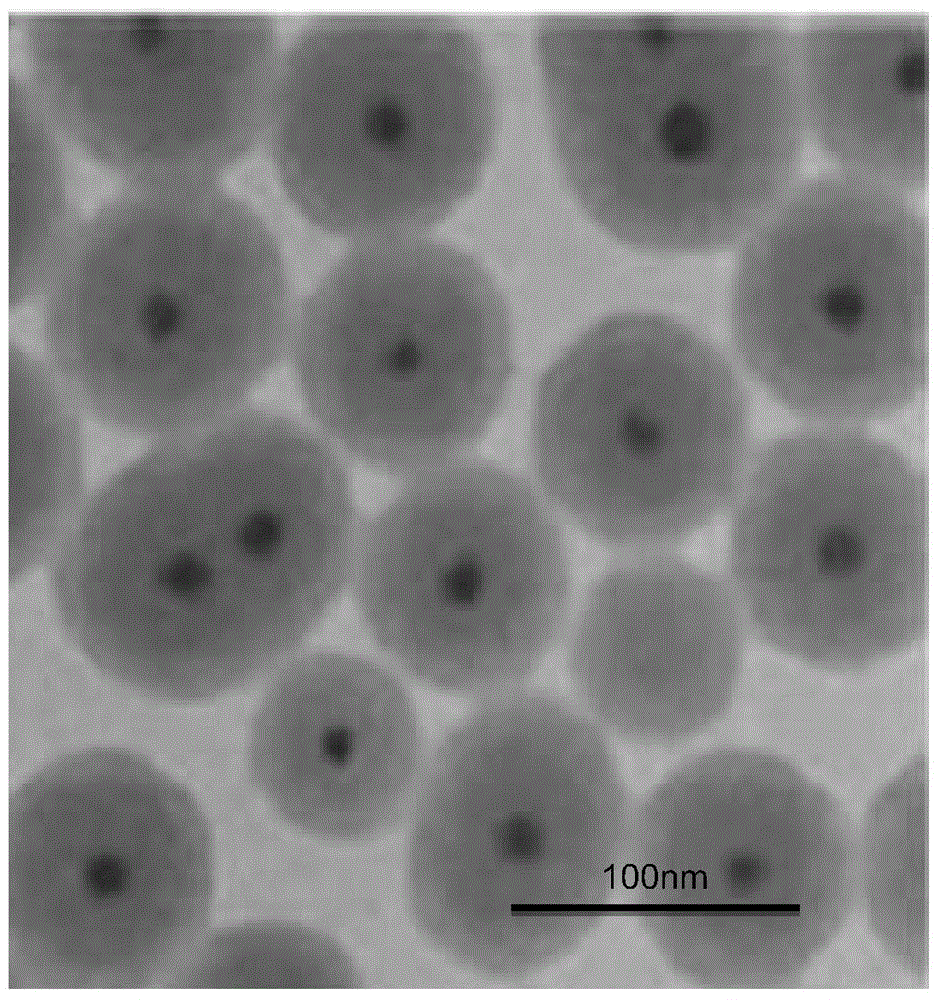

[0025] Add acetic acid to 100ml of 0.001mol / L ammonium metatungstate aqueous solution to make the pH value of the solution 4, put it in a hydrothermal reaction kettle at 160°C for 3 hours and cool to room temperature to obtain particles with an average diameter of 10nm and a pH value of 6 Nano WO 3 Hydrosol, heat the hydrosol to 100°C, add 8.2g of ethyl titanate to make the molar ratio of Ti:W 30:1, keep the temperature for 5h, and cool it to room temperature to obtain a solid content of 5.6% and an average particle size of 80nm The hydrosol, the transmission electron micrographs of its nanoparticles and the photoresponse curve are as follows figure 2 with 5 shown.

Embodiment 3

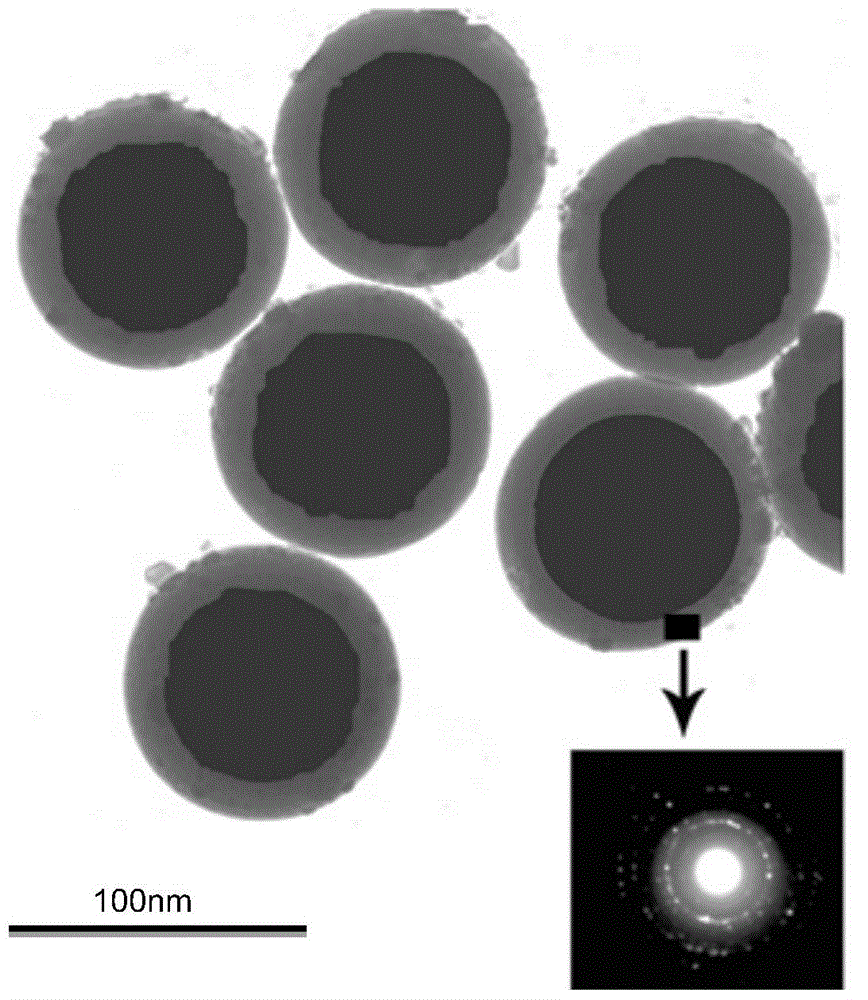

[0027] Add nitric acid to 100ml of 0.005mol / L ammonium metatungstate aqueous solution to make the pH value of the solution 2, place it in a hydrothermal reaction kettle at 260°C for 18 hours and cool to room temperature to obtain particles with an average diameter of 60nm and a pH value of 4 Nano WO 3 Water sol, heat the water sol to 80°C, add 10.2g butyl titanate to make the molar ratio of Ti:W 5:1, keep the temperature for 3 hours, and cool it to room temperature, you can get a solid content of 3.8% and an average particle size of 90nm The hydrosol, the transmission electron micrographs of its nanoparticles and the photoresponse curve are as follows image 3 with 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com