Hyaluronic acid vitamin E derivative and preparation and application

A technology of hyaluronic acid and sodium hyaluronate, applied in the direction of liposome delivery, can solve the problems of biocompatibility, biotoxicity, drug-carrying system limitation, etc., and achieve the effect of excellent biocompatibility and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

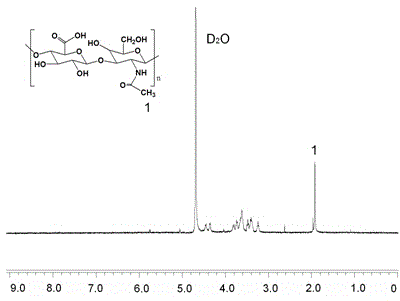

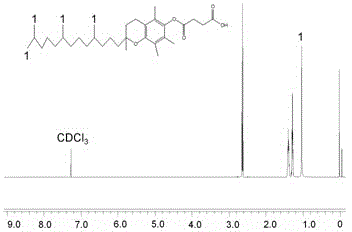

[0036] (1) Synthesis of hyaluronic acid and vitamin E derivatives

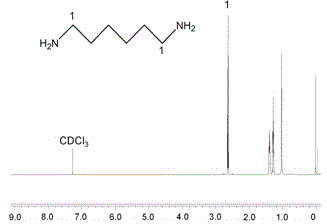

[0037] Weigh 0.5g vitamin E succinate (VES), 0.45g 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC), 0.1g N-hydroxysulfosuccinimide (NHS) into a 50ml single-necked flask, add 25ml dimethyl sulfoxide (DMSO), stir and dissolve at room temperature for 60min. Another 0.2 g of hexamethylenediamine was weighed, dissolved in 10 ml of DMSO, slowly added dropwise to the reaction solution, stirred at room temperature for more than 8 hours, and the reaction solution A was obtained.

[0038] Weigh 0.38g sodium hyaluronate (HA-Na) with a molecular weight of about 6700 (n+m=17), 0.45g 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride (EDC ), 0.1g perimide (NHS) into a 100ml single-necked flask, add 60ml of water and ethanol mixed solution, stir and dissolve at room temperature for 60min, slowly add reaction solution A dropwise, and stir at room temperature for 4h. The reaction solution was dialyze...

Embodiment 2

[0064] (1) Weigh 0.5g vitamin E succinate (VES), 0.45g 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC), 0.1g N-hydroxysulfosuccinate Put imide (NHS) into a 50ml single-necked flask, add 25ml dimethyl sulfoxide (DMSO), stir and dissolve at room temperature for 60min. Another 0.2g of cystamine was weighed, dissolved in 10ml of DMSO, slowly added dropwise to the reaction solution, and stirred at room temperature for more than 8 hours to obtain the reaction solution A.

[0065]Weigh 0.38g sodium hyaluronate (HA-Na) with a molecular weight of about 6700 (n+m=17), 0.45g 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride (EDC ), 0.1g perimide (NHS) into a 100ml single-necked flask, add 60ml of water and ethanol mixed solution, stir and dissolve at room temperature for 60min, slowly add reaction solution A dropwise, and stir at room temperature for 8h. The reaction solution was dialyzed in deionized water for 3-4 days to remove the catalyst and unreacted monom...

Embodiment 3

[0073] (1) Weigh 0.5g vitamin E succinate (VES), 0.45g 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC), 0.1g N-hydroxysulfosuccinate Put the imide (NHS) into a 50ml single-necked flask, add 25ml dimethyl sulfoxide (DMSO), stir and dissolve at room temperature for 60min. Another 0.2 g of 3-aminopropanol was weighed, dissolved in 10 ml of DMSO, slowly added dropwise to the reaction solution, stirred at room temperature for more than 8 hours, and the reaction solution A was obtained.

[0074] Weigh 0.38g sodium hyaluronate (HA-Na) with a molecular weight of about 6700 (n+m=17), 0.45g 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride (EDC ), 0.1g 4-dimethylaminopyridine (DMAP) into a 100ml single-necked flask, add 60ml of water and ethanol mixed solution, stir and dissolve at room temperature for 60min, slowly add reaction solution A dropwise, and stir at room temperature for 8h. The reaction solution was dialyzed in deionized water for 3-4 days to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com