Treating technology of slack coal

A technology for processing process and crude gas, applied in the field of coal chemical industry, can solve the problems of complex process, relatively large investment, low energy efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

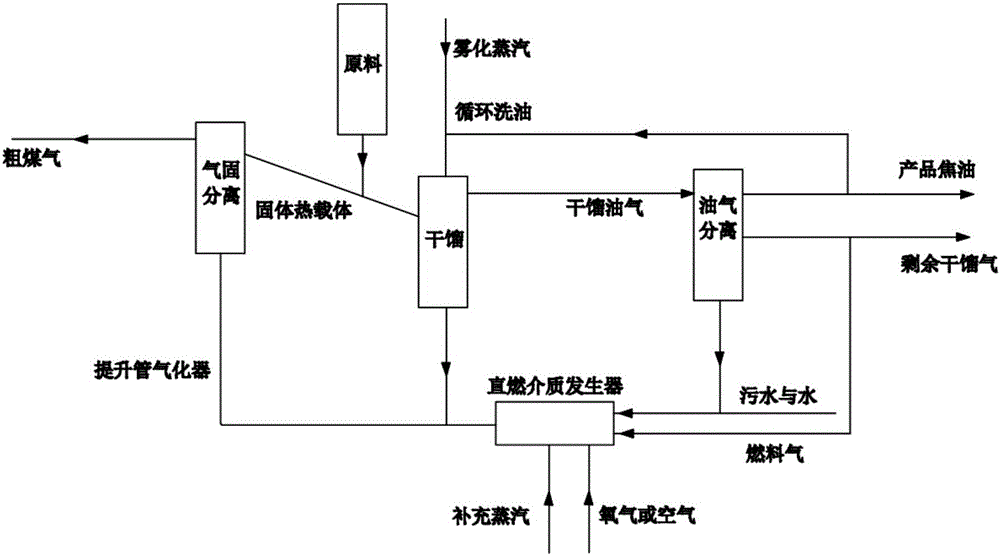

Method used

Image

Examples

Embodiment 1

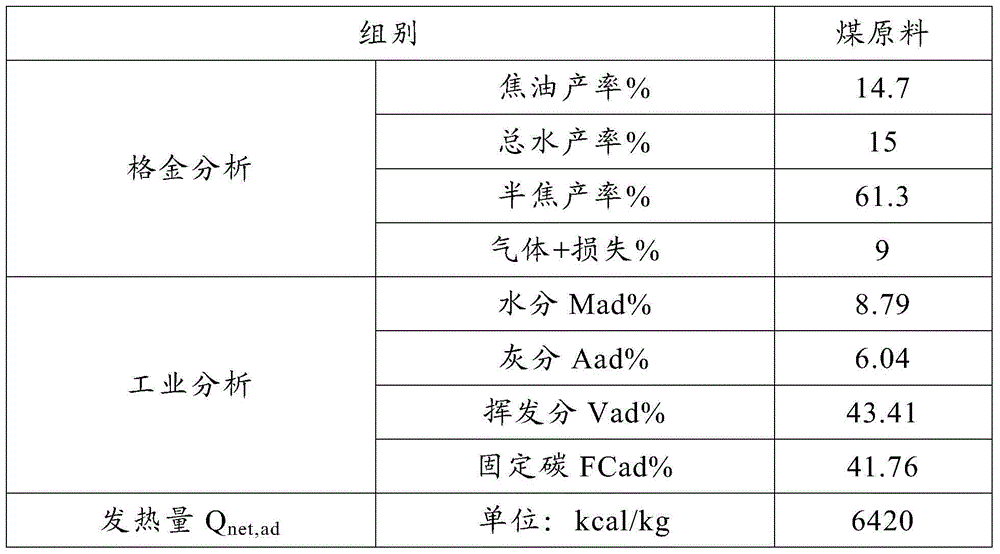

[0064] The data in this embodiment is the optimal condition in this implementation, and does not limit the scope of application of the present invention. The data in this embodiment are all provided on the basis of 1 ton of raw material.

[0065] In this example, a certain long-flame coal is used as the raw material for the clean and efficient production method of all resources in the fluidized carbonization-gasification coupling process. In this example, the fine coal raw material with a particle size of 0-3 mm is preferred (other particle size ranges are not limited). The particle size range is the optimal range of the coal’s overall cost. The high-temperature solid heat carrier of about 950°C from the heat carrier settler passes through the downcomer, and the hydrogen-rich transport gas (coal gas produced by gasification, dry distillation gas, or other The extracted hydrogen-rich gas) is sent to the coal char mixing pipe, and mixed with the raw raw coal from the raw material...

Embodiment 2

[0074] The process of this embodiment is basically the same as that of Embodiment 1, the main difference is that dry distillation and gasification are operated at high pressure, and the pressure is increased to 2MPa; the delivery gas is pure hydrogen; the gas fuel of the direct combustion medium generator is changed to gasified crude gas (contains less methane).

[0075] Adopt the raw material identical with embodiment 1, compared with embodiment 1 effect is as follows:

[0076] 1 ton of coal produces 166.99kg of tar, and the yield of Gejin oil increases from 87% to 113.6%;

[0077] 1 ton of coal produces crude gas 1120m 3 , retort gas 97m 3 , methane in the total gas product increases by 45m 3 , suitable for the production of coal-based natural gas; embodiment 1 is suitable for the production of coal gas synthesis products due to the combustion of dry distillation gas with high methane content. Table 1 Raw coal data table

[0078]

[0079] Table 2 Tar distillation ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com