Elastic body for actuator, and piezoelectric actuator

A piezoelectric actuator, elastomer technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem of insufficient output characteristics, Low surface vibration speed, inability to ensure insulation and other problems, achieve the effect of small size and excellent light weight, increase displacement, improve electrical insulation and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

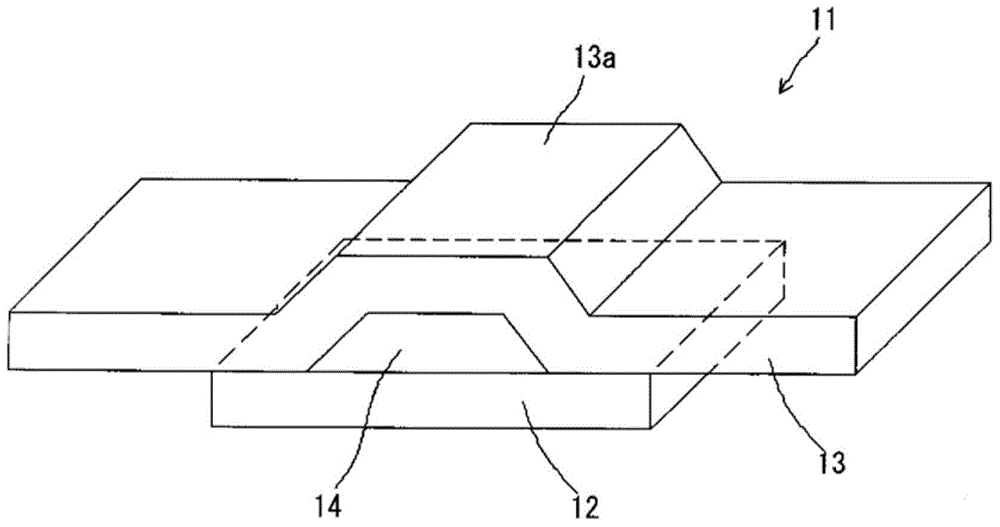

[0288] Machining of PEEK, production and Figure 6 The elastomer 43 shown is an elastomer of the same shape.

Embodiment 2

[0293] Using CF-containing PPS, cutting process is carried out so that the orientation direction of the carbon fiber is parallel to the contact surface of the piezoelectric element and the elastic body, and parallel to the longitudinal direction of the elastic body, and the Figure 6 The elastomer 43 shown is an elastomer of the same shape.

Embodiment 3

[0295] Using CF-containing PPS, cutting process is performed so that the orientation direction of carbon fiber is perpendicular to the contact surface between piezoelectric element and elastic body, and the Figure 6 The elastomer 13 shown is an elastomer of the same shape.

[0296] Using the elastic bodies obtained in Examples 2 and 3, a linear ultrasonic motor was manufactured, and the results obtained by evaluating the maximum vibration velocity are shown in Figure 10 middle. From Figure 10 As a result, it can be seen that compared with the elastic body of Example 3, the maximum vibration velocity of the elastic body of Example 2 under high voltage is further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com