Manufacturing method of seamless steel pipe

A manufacturing method and technology of seamless steel pipe, applied in the field of seamless steel pipe, can solve the problems of casualty accident, property loss, low strength, cylinder explosion, etc., and achieve the effect of ensuring quality and structural strength, good welding performance, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The steps of this embodiment are the same as those described above, and the alloying element ratio is:

[0059] Carbon: 0.19%; Silicon: 0.30%; Manganese: 1.21%; Phosphorus: 0.009%; S: 0.01%; Chromium: 0.021%; Nickel: 0.027%; Molybdenum: 0.001%; Titanium: 0.004%; Vanadium: 0.046%; Copper: 0.039%; Aluminum: 0.025%; Carbon equivalent: 0.41%; the rest is molten steel.

Embodiment 2

[0061] This embodiment is the same as the first embodiment, and the difference lies in the ratio of alloy elements. The ratio of alloy elements in this embodiment is:

[0062] Carbon: 0.17%; silicon: 0.28%; manganese: 1.07%; phosphorus: 0.009%; sulfur: 0.011%; chromium: 0.022%; nickel: 0.028%; molybdenum: 0.001%; titanium: 0.004%; vanadium: 0.041%; Copper: 0.038%; Aluminum: 0.015%; Carbon equivalent: 0.37%; the rest is molten steel.

Embodiment 3

[0064] This embodiment is the same as the first embodiment, and the difference lies in the ratio of alloy elements. The ratio of alloy elements in this embodiment is:

[0065] Carbon: 0.15%; Silicon: 0.27%; Manganese: 0.98%; Phosphorus: 0.009%; S: 0.011%; Chromium: 0.022%; Nickel: 0.028%; Molybdenum: 0.001%; Titanium: 0.004%; Vanadium: 0.041%; Copper: 0.038%; Aluminum: 0.015%; Carbon equivalent: 0.33%; the rest is molten steel.

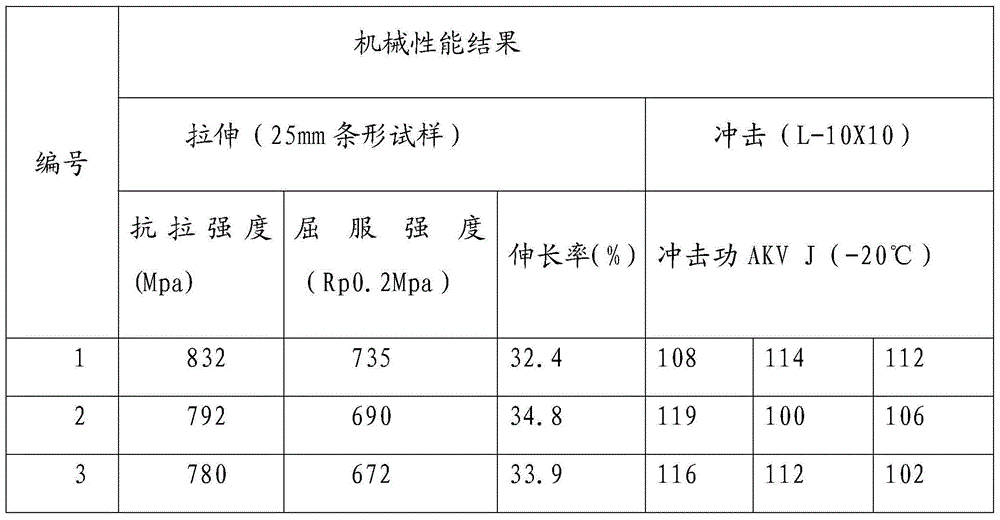

[0066] The performance indicators achieved by the three embodiments are shown in Table 1:

[0067] Table I

[0068]

[0069] From the performance indicators in Table 1:

[0070] Among them, the seamless steel pipe manufactured in Example 1 has the highest tensile performance, the tensile performance of the seamless steel pipe manufactured in Example 3 is at the lower limit of the design requirements, and the tensile performance of the seamless steel pipe manufactured in Example 2 is in the implementation. Between Example 1 and Example 3.

[0071] At the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com