Ultraviolet detection converter and methods for preparing and using same

A converter, ultraviolet technology, applied in instruments, semiconductor devices, optics, etc., can solve the problems of high cost and difficult development of readout circuits, and achieve the effect of prolonging service life, low price, and cheap ultraviolet detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

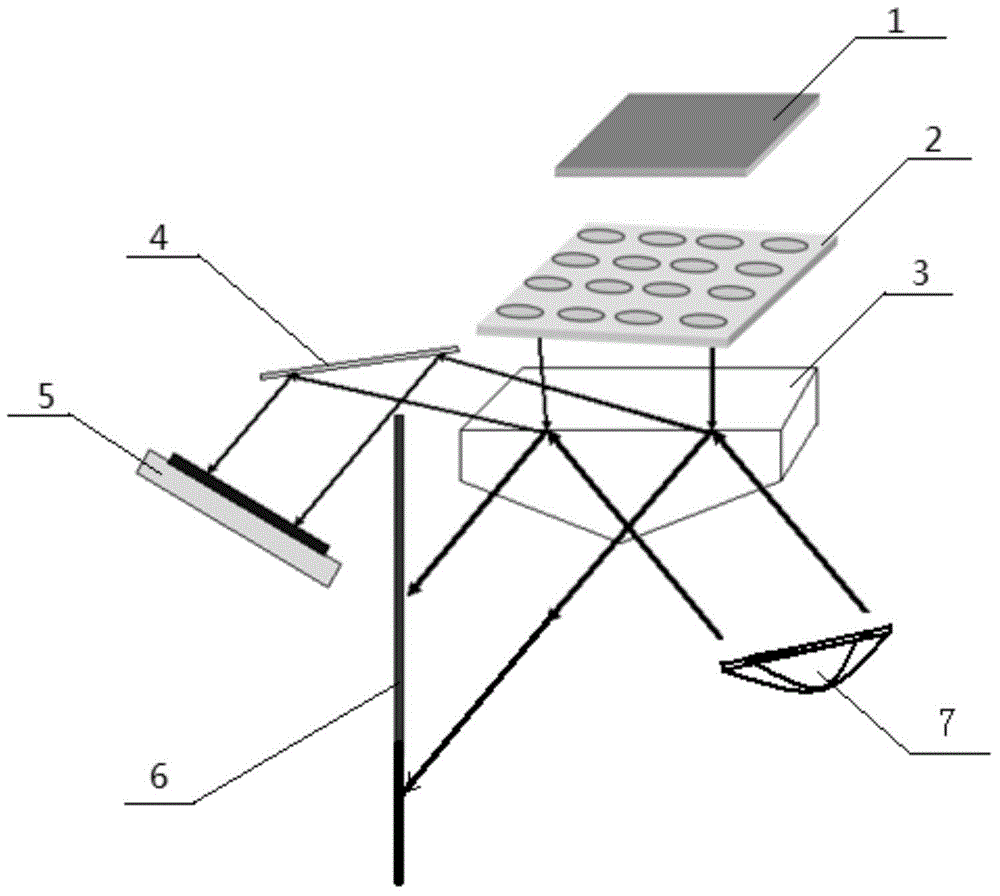

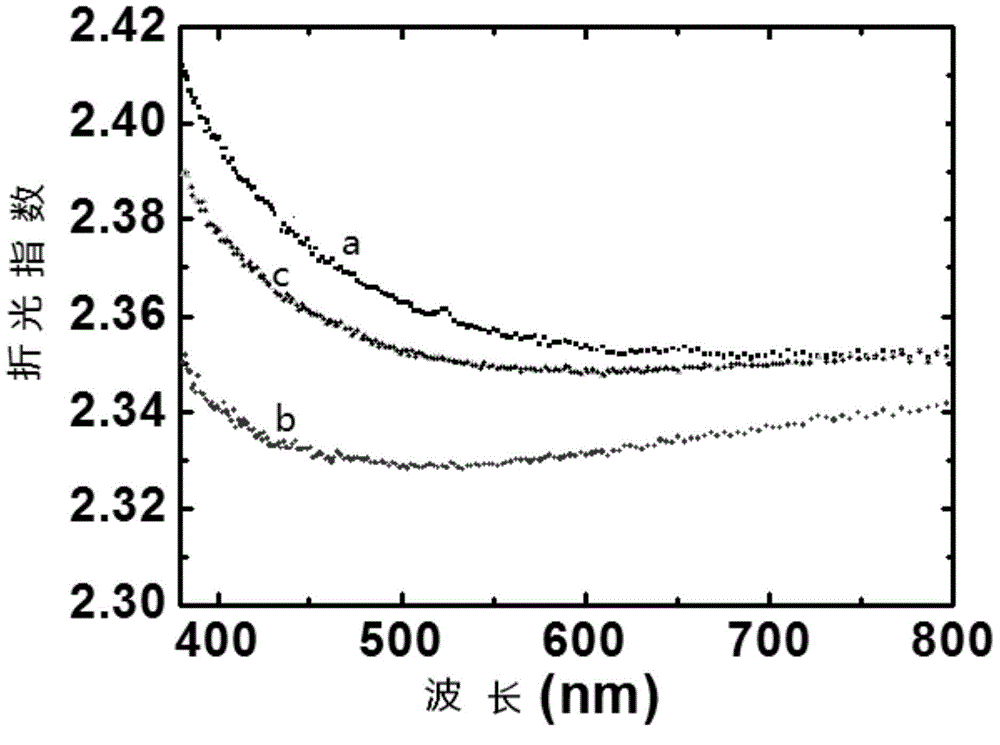

[0023] Embodiment 1: The ultraviolet detection converter of this embodiment is an optical isosceles prism cut from a transparent relaxor ferroelectric ceramic material, wherein the apex angle of the isosceles triangle in the cross section of the prism is 150° to 165°, and the relaxation The bandgap width Eg of the Henan ferroelectric ceramic material is 3.0-4.0eV, the Curie temperature is 10-60°C, and the value of the decrease in the refractive index caused by ultraviolet radiation is ≥0.02.

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the relaxor ferroelectric ceramic material is lead lanthanum zirconium titanium ytterbium niobate (Pb 0.90 La 0.10 [(Yb 1 / 2 Nb 1 / 2 ) 0.15 (Zr 0.425 Ti 0.575 ) 0.85 ] 0.975 o 3 ), or the relaxor ferroelectric ceramic material is lead lanthanum zirconate titanate (Pb 1-x La x )(Zr y Ti 1-y ) 1-x / 4 o 3 , PLZT), where x=0.1, y=0.65; or the relaxation ferroelectric ceramic material PbMg 1 / 3 Nb 2 / 3 o 3 The mass percentage is 71%, lead titanate (PbTiO 3 ) with a mass percentage of 29% of the formed PbMg 1 / 3 Nb 2 / 3 o 3 with PbTiO 3 of solid solution. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and embodiment one or two is that the two symmetrical isosceles prism surfaces of the isosceles triangular prism are vapor-deposited or deposited multi-layer dielectric film, and the multi-layer dielectric film has a central wavelength of 800nm light. High transmittance; others are the same as those in Embodiment 1 or 2. Of which SiO 2 with TiO 2 A multilayer film with an alternating periodic structure, the film thickness is λ / 4, and λ is a central wavelength of 800nm. The preparation of this multilayer dielectric antireflection film is a conventional film preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com