Honeycomb type SCR denitration catalyst and preparation method thereof

A denitration catalyst and honeycomb technology, applied in the field of denitration catalysts, can solve the problems of good chemical and thermal stability, high catalyst cost, and high anti-poisoning performance, and achieve good chemical and thermal stability, high solution cost, and anti-poisoning performance. high performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

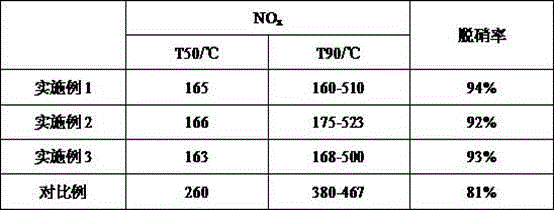

Examples

Embodiment 1

[0052] A honeycomb SCR denitration catalyst, prepared from the following components in parts by weight:

[0053] 7 parts of diatomaceous earth;

[0054] 11 parts of titanium dioxide;

[0055] 18 parts of molecular sieves;

[0056] 8 parts of praseodymium oxide;

[0057] 9 parts of yttrium oxide;

[0058] Iron oxide 10 parts

[0059] 20 parts of polyferrocene;

[0060] 4 parts of talcum powder;

[0061] 6 parts of simethicone oil;

[0062] 7 parts of phenolic resin;

[0063] Dolomite 8 parts;

[0064] 4 parts of polytetrafluoroethylene powder;

[0065] 3 parts polystyrene glycol ester fiber;

[0066] 1 part of sodium cetylbenzenesulfonate;

[0067] Sodium Lauryl Sulfate 2 parts;

[0068] 2 parts of polyoxyethylene ether;

[0069] 8 parts of deionized water.

[0070] The preparation technology of cellular SCR denitration catalyst of the present invention is as follows:

[0071] (1) Take 7 parts of diatomite, 11 parts of titanium dioxide, and 18 parts of molecular si...

Embodiment 2

[0082] A honeycomb SCR denitration catalyst, prepared from the following components in parts by weight:

[0083] 8 parts of diatomaceous earth;

[0084] 15 parts of titanium dioxide;

[0085] 19 parts of molecular sieves;

[0086] 11 parts of praseodymium oxide;

[0087] 10 parts of yttrium oxide;

[0088] Iron oxide 12 parts

[0089] 22 parts of polyferrocene;

[0090] 5 parts of talcum powder;

[0091] 7 parts of simethicone;

[0092] 8 parts of phenolic resin;

[0093] Dolomite 9 parts;

[0094] 6 parts of polytetrafluoroethylene powder;

[0095] 4 parts polystyrene glycol ester fiber;

[0096] 2 parts of sodium cetylbenzenesulfonate;

[0097] 3 parts sodium lauryl sulfate;

[0098] 3 parts of polyoxyethylene ether;

[0099] 9 parts of deionized water.

[0100] The preparation technology of cellular SCR denitration catalyst of the present invention is as follows:

[0101] (1) Take 8 parts of diatomite, 15 parts of titanium dioxide, and 19 parts of molecular s...

Embodiment 3

[0112] A honeycomb SCR denitration catalyst, prepared from the following components in parts by weight:

[0113] 13 parts of diatomaceous earth;

[0114] 20 parts of titanium dioxide;

[0115] 25 parts of molecular sieves;

[0116] 12 parts of praseodymium oxide;

[0117] 13 parts of yttrium oxide;

[0118] Iron oxide 15 parts

[0119] 25 parts of polyferrocene;

[0120] 6 parts of talcum powder;

[0121] 9 parts of simethicone;

[0122] 8 parts of phenolic resin;

[0123] Dolomite 12 parts;

[0124] 7 parts of polytetrafluoroethylene powder;

[0125] 5 parts of polystyrene glycol ester fiber;

[0126] 3 parts of sodium cetylbenzenesulfonate;

[0127] Sodium lauryl sulfate 5 parts;

[0128] 4 parts of polyoxyethylene ether;

[0129] 10 parts of deionized water.

[0130] The preparation technology of cellular SCR denitration catalyst of the present invention is as follows:

[0131] (1) Take 13 parts of diatomaceous earth, 20 parts of titanium dioxide, and 25 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com