A kind of processing method of phosphoric acid waste liquid

A treatment method, phosphoric acid technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high energy consumption, large equipment volume, and large investment in the concentration process. To achieve the effect of protecting the natural ecological environment and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

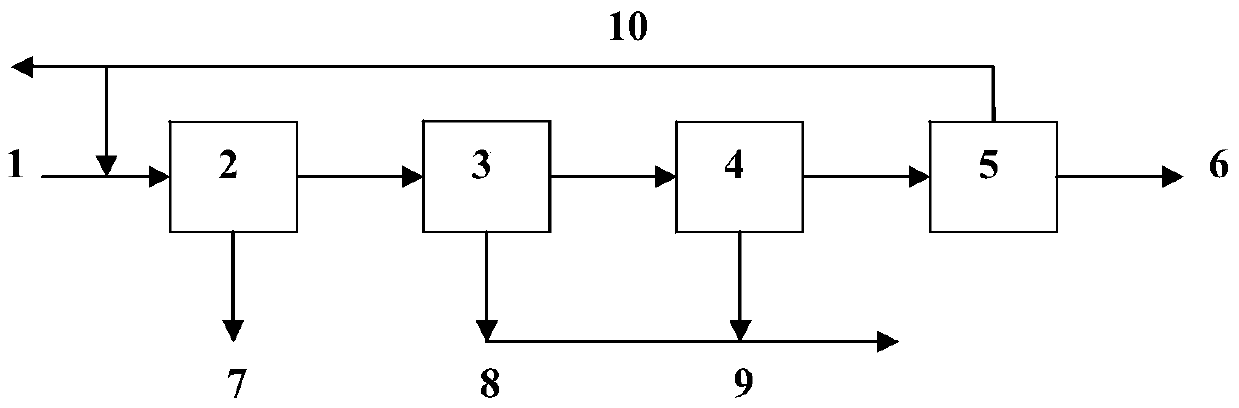

[0069] For a schematic diagram of the process, see figure 1 . The water quality characteristic of phosphoric acid waste liquid in embodiment 1 is: PO 4 3- 323813mg / l, Na + 1241mg / l, K + 576mg / l, Mg 2+ 17005mg / l, Ca 2+ 1427mg / l.

[0070] The operation steps are as follows:

[0071] (1) Microfiltration. Entering the phosphoric acid waste liquid into a microfiltration unit for treatment to remove calcium phosphate, magnesium phosphate and other suspended matter in the phosphoric acid waste liquid;

[0072] (2) Anion exchange. Put the phosphoric acid waste liquid treated in step (1) into the anion exchange resin for ion exchange, so that the phosphate ions in the waste liquid are adsorbed on the anion exchange resin. The salt-containing waste liquid is discharged from the anion exchange resin, and then discharged directly or combined with other process wastewater for treatment.

[0073] After the anion exchange resin has been used for 5 days, use 1 mol / L sodium hydroxid...

Embodiment 2

[0083] For a schematic diagram of the process, see figure 1 . The water quality characteristics of phosphoric acid waste liquid in embodiment 2 are the same as embodiment 1.

[0084] The operating steps are the same as in Example 1. Wherein different from Example 1, after the anion exchange resin was used for 6 days, a 1.5mol / L sodium hydroxide solution was used for regeneration treatment; after the cation exchange resin was used for 6 days, a 3.5mol / L hydrochloric acid solution was used for regeneration treatment;

[0085] In the above steps, the microfiltration used is Gore microfiltration, and the Gore microfiltration membrane material is a PTFE membrane material with a membrane pore size of 0.2 μm; the anion exchange resin used is a polystyrene series strong basic anion exchange resin; the cation exchange resin used is Polystyrene-based strong acid cation exchange resin; the membrane distillation module used is polytetrafluoroethylene (PTFE) hollow fiber hydrophobic memb...

Embodiment 3

[0091] For a schematic diagram of the process, see figure 1 . The water quality characteristics of phosphoric acid waste liquid in embodiment 3 are the same as embodiment 1.

[0092] The operating steps are the same as in Example 1. Wherein different from Example 1, after the anion exchange resin was used for 6 days, a 1.5mol / L sodium hydroxide solution was used for regeneration treatment; after the cation exchange resin was used for 6 days, a 3.5mol / L hydrochloric acid solution was used for regeneration treatment;

[0093] In the above steps, the microfiltration used is Gore microfiltration, and the Gore microfiltration membrane material is a PTFE membrane material with a membrane pore size of 0.2 μm; the anion exchange resin used is a polystyrene series strong basic anion exchange resin; the cation exchange resin used is Polystyrene-based strong acid cation exchange resin; the membrane distillation module used is a polytetrafluoroethylene (PTFE) hollow fiber hydrophobic me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com