Microsphere oil displacement agent used for improving recovery efficiency

A technology of recovery factor and oil displacement agent, applied in the field of microsphere oil displacement agent, can solve the problems of inhomogeneity, small sweep coefficient of injected fluid, low recovery factor, etc. Resistance to salinity, the effect of increasing crude oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

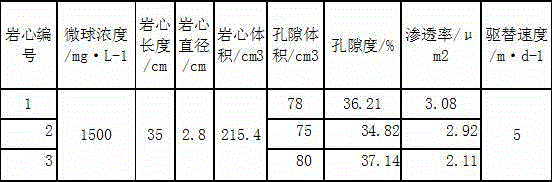

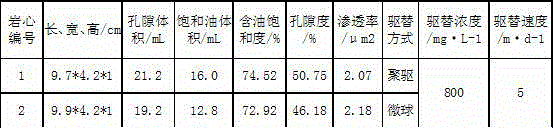

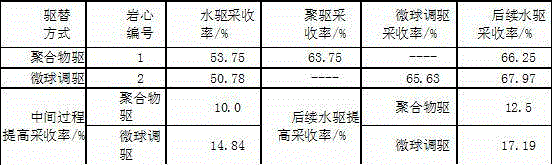

Image

Examples

Embodiment 1

[0024] The microsphere oil displacement agent for enhanced oil recovery comprises the following raw materials in parts by weight:

[0025] 100 grams of deionized water Acrylamide crystals 13.3 grams

[0026] Styrene 2.3 grams Cross-linking agent 0.3 grams

[0027] Ammonium persulfate 0.7g Potassium persulfate 0.2g

[0028] Oil 160g Span-80 6.4g

[0029] Tween-80 1.6 g.

[0030] The oil is mineral oil, white oil or vegetable oil.

[0031] The cross-linking agent is N, N / - Methylenebisacrylamide.

[0032] The preparation method of microsphere oil displacement agent for enhancing oil recovery comprises the following steps:

[0033] 1) Prepare the oil phase:

[0034] Add oil into a small kettle, start stirring, then put Span-80 and Tween-80 into the reaction kettle, stir, heat the materials in the reaction kettle, and keep the temperature constant for half an hour;

[0035] 2) Prepare the water phase:

[0036] Add acrylamide crystals, crosslinking agent and ammonium per...

Embodiment 2

[0045] The microsphere oil displacement agent for enhanced oil recovery comprises the following raw materials in parts by weight:

[0046] 50 grams of deionized water Acrylamide crystals 8 grams

[0047] Styrene 1 g Crosslinker 0.1 g

[0048] Ammonium persulfate 0.1g Potassium persulfate 0.1g

[0049] Oil 100g Span-80 1g

[0050] Tween-80 0.5 g.

[0051] The oil is mineral oil, white oil or vegetable oil.

[0052] The cross-linking agent is N, N / - Methylenebisacrylamide.

[0053] The preparation method of microsphere oil displacement agent for enhancing oil recovery comprises the following steps:

[0054] 1) Prepare the oil phase:

[0055] Add oil into a small kettle, start stirring, then put Span-80 and Tween-80 into the reaction kettle, stir, heat the materials in the reaction kettle, and keep the temperature constant for half an hour;

[0056] 2) Prepare the water phase:

[0057] Add acrylamide crystals, crosslinking agent and ammonium persulfate to the prepared ...

Embodiment 3

[0064] The microsphere oil displacement agent for enhanced oil recovery comprises the following raw materials in parts by weight:

[0065] 200g deionized water 15g acrylamide crystals

[0066] Styrene 5 g Cross-linking agent 0.9 g

[0067] Ammonium persulfate 2g Potassium persulfate 0.5g

[0068]Oil 260g Span-80 5g

[0069] Tween-80 2 g.

[0070] The oil is mineral oil, white oil or vegetable oil.

[0071] The cross-linking agent is N, N / - Methylenebisacrylamide.

[0072] The preparation method of microsphere oil displacement agent for enhancing oil recovery comprises the following steps:

[0073] 1) Prepare the oil phase:

[0074] Add oil into a small kettle, start stirring, then put Span-80 and Tween-80 into the reaction kettle, stir, heat the materials in the reaction kettle, and keep the temperature constant for half an hour;

[0075] 2) Prepare the water phase:

[0076] Add acrylamide crystals, crosslinking agent and ammonium persulfate to the prepared deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com