A method and device for forming a 3D printing ice casting sand mold

A 3D printing and sand molding technology, which is applied to casting molding equipment, casting mold components, casting molds, etc., can solve the problems of high incidence of casting defects, easy pollution of the environment, high content of sand mold resin, etc., and achieve low cost and wide source of materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

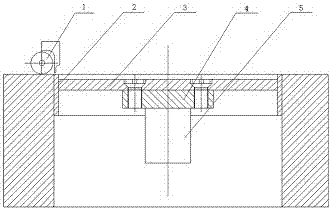

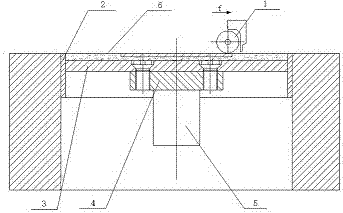

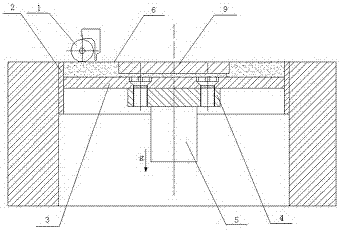

[0034] The 3D printing technology that the present invention proposes makes the method for frozen mold, such as Figure 1 to Figure 11 As shown, firstly, the refractory sand powder used for making molds is cooled to -40°C to -10°C for later use. The equipment uses a computer-controlled sand spreading system. First, a layer of sand is spread on the workbench, and then the computer according Based on the shape data information of the cut surface, the array nozzle device is driven to spray water or aqueous solution at the forming section, and the sprayed water or aqueous solution meets the low-temperature molding sand and freezes into ice, and the layer of sand is frozen together; after the first layer of forming is completed, work The table is lowered by one layer, and then the second layer of sand, water or aqueous solution is sprayed. The sprayed sand layer freezes the water or aqueous solution into ice, and the layer of sand and this layer are frozen together with the previous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com