Nanoscale sheet-SAPO-34 molecular sieve and synthetizing method thereof

A SAPO-34, nano-scale technology, applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali-exchanged phosphate, etc., can solve the problems of complex synthesis method and high cost of SAPO-34 molecular sieve, and shorten the molecular diffusion path and reduce the cost. The effect of increased rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

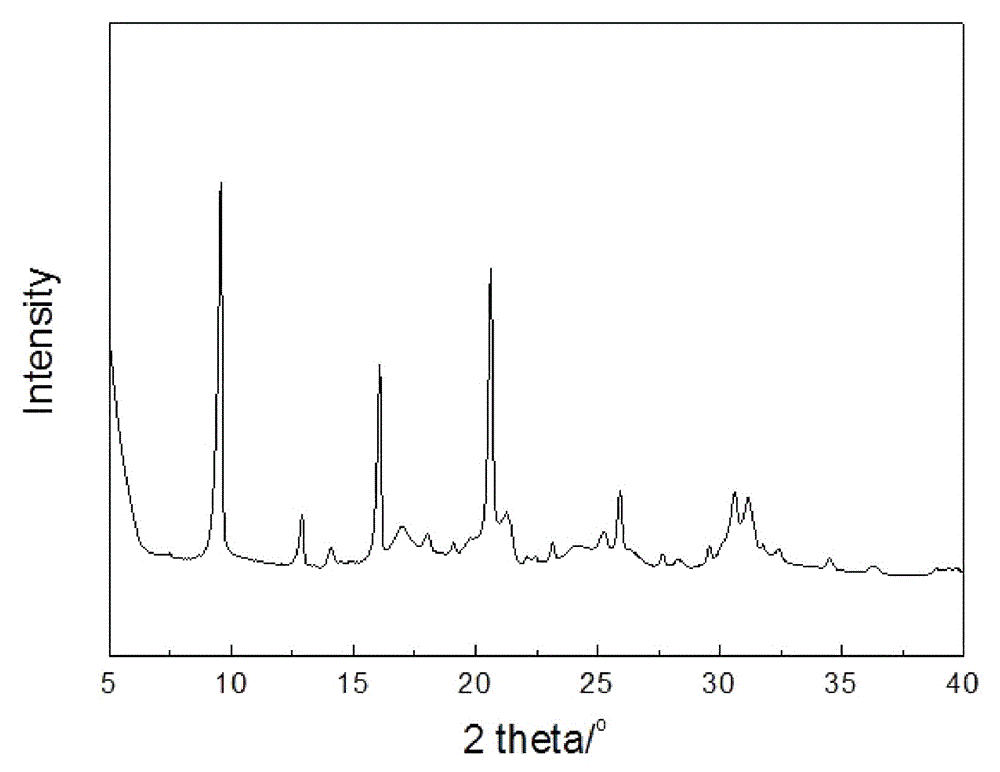

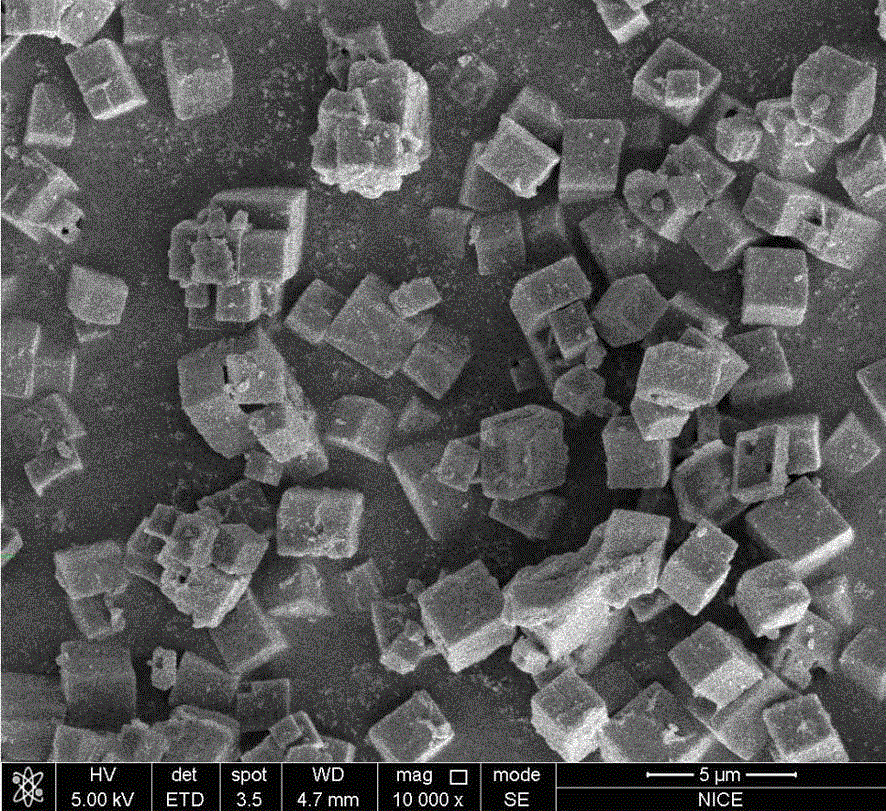

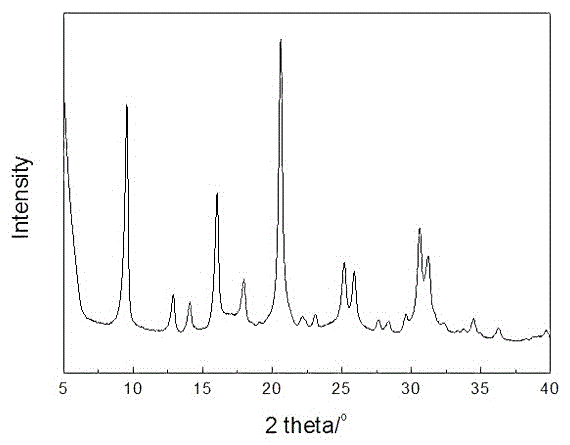

[0023] Example 1 Add pseudoboehmite, phosphoric acid, ammonium dihydrogen phosphate, white carbon black, cetyltrimethylammonium bromide and water into a three-necked flask, connect a condenser to the three-necked flask, and place the above mixture in an oil bath The reaction was stirred at reflux for 24 hours at 75°C. Then, triethylamine was added into the three-necked flask, and the stirring reaction was continued for 4 hours at room temperature (25° C.). Take Al 2 o 3 Pseudoboehmite in terms of P 2 o 5 Phosphoric acid and ammonium dihydrogen phosphate, SiO 2 The calculated molar ratio of white carbon black, cetyltrimethylammonium bromide, triethylamine and water is 1:1:0.3:0.1:3:100. Wherein, the molar ratio of phosphoric acid to ammonium dihydrogen phosphate is 4:1. The obtained sol was put into a hydrothermal reaction kettle, and crystallized at 200° C. for 50 hours. The crystallized mixture was filtered, the obtained solid was washed with deionized water at room ...

Embodiment 2

[0025] Example 2 Pseudoboehmite, phosphoric acid, ammonium dihydrogen phosphate, silica sol, cetyltrimethylammonium bromide and water were added into a three-necked flask, a condenser was connected to the three-necked flask, and the above mixture was placed in an oil bath The reaction was stirred and refluxed at 50°C for 48 hours. Then, triethylamine was added into the three-necked flask, and the stirring reaction was continued at room temperature (25° C.) for 12 hours. Take Al 2 o 3 Pseudoboehmite in terms of P 2 o 5 Phosphoric acid and ammonium dihydrogen phosphate, SiO 2 The molar ratio of silica sol, cetyltrimethylammonium bromide, triethylamine and water is 1:0.8:0.2:0.1:3:100. Wherein, the molar ratio of phosphoric acid to ammonium dihydrogen phosphate is 10:1. The obtained sol was put into a hydrothermal reaction kettle, and crystallized at 200° C. for 50 hours. The crystallized mixture was filtered, the obtained solid was washed with deionized water at room te...

Embodiment 3

[0027] Example 3 Add pseudo-boehmite, phosphoric acid, ammonium dihydrogen phosphate, silica sol, cetyltrimethylammonium bromide and water into a three-necked flask, and stir and reflux in an oil bath at 80°C for 36 hours. Then, triethylamine was added into the three-necked flask as a template agent, and the stirring reaction was continued for 8 hours at room temperature (25° C.). Take Al 2 o 3 Pseudoboehmite in terms of P 2 o 5 Phosphoric acid and ammonium dihydrogen phosphate, SiO 2 The calculated molar ratio of silica sol, cetyltrimethylammonium bromide, triethylamine and water is 1:1.2:1:0.2:4:50. Wherein, the molar ratio of phosphoric acid to ammonium dihydrogen phosphate is 1:1. The obtained sol was put into a hydrothermal reaction kettle, and crystallized at 220° C. for 10 hours. The crystallized mixture was filtered, the obtained solid was washed with deionized water at room temperature (25°C), dried at 120°C for 8 hours, and then calcined at 550°C for 3 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com