Inner wall coating for flue gas desulfurization pump and preparation method thereof

A desulfurization pump and coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as sewage treatment problems, and achieve the effect of prolonging service life, simple method and improving comprehensive application performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

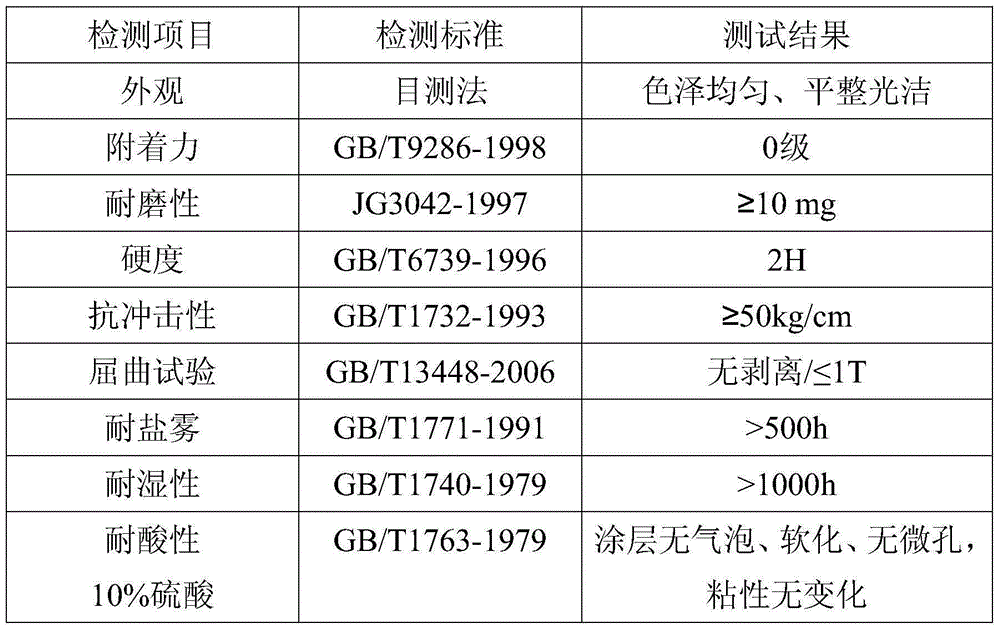

Image

Examples

Embodiment 1

[0018] (1) first soak 12kg of nano ceramic powder in 5 times the mass concentration 10% hydrochloric acid solution for 1h, then filter, wash with water, the obtained solid is placed in a dryer to dry, and finally ball-milled into a fine powder by a ball mill;

[0019] (2) Add 80kg of phenolic epoxy resin and the nano-ceramic powder treated in step (1) into 50kg of ethanol, disperse evenly and let stand for 30min, then add 6kg of carboxymethyl chitosan, and the mixture is heated to ultrasonic frequency 22kHz, power Ultrasonic treatment 30min under 100W, obtains material I;

[0020] (3) material 1, 20kg fluorocarbon resin and 8kg tung oil are joined in the high-speed mixer, 7kg hydrogenated castor oil and 2kg oxidized polyethylene wax are added after mixing 10min, then be warming up to 100-110 DEG C and mix 15min, after cooling down get material II;

[0021] (4) 10kg of zeolite powder and 4kg of copper oxide powder were uniformly dispersed in 100kg of water first, then ultrason...

Embodiment 2

[0023] (1) first soak 15kg of nano ceramic powder in 5 times the mass concentration 10% hydrochloric acid solution for 1h, then filter, wash with water, and the obtained solid is placed in a dryer to dry, and finally ball-milled into a fine powder by a ball mill;

[0024] (2) Add 85kg of phenolic epoxy resin and the nano-ceramic powder treated in step (1) into 55kg of ethanol, disperse evenly and let stand for 30min, then add 7kg of carboxymethyl chitosan, and the mixture is heated to ultrasonic frequency 22kHz, power Ultrasonic treatment 30min under 100W, obtains material I;

[0025] (3) material 1, 25kg fluorocarbon resin and 9kg tung oil are joined in the high-speed mixer, add 8kg hydrogenated castor oil and 3kg oxidized polyethylene wax after mixing 10min, then be warming up to 100-110 ℃ and mix 15min, after cooling down get material II;

[0026] (4) Disperse 12kg of zeolite powder and 5kg of copper oxide powder evenly in 110kg of water first, then ultrasonically treat it...

Embodiment 3

[0028] (1) first soak 15kg of nano ceramic powder in 5 times the mass concentration 10% hydrochloric acid solution for 1h, then filter, wash with water, and the obtained solid is placed in a dryer to dry, and finally ball-milled into a fine powder by a ball mill;

[0029] (2) 90kg of phenolic epoxy resin and the nano-ceramic powder treated in step (1) were added to 60kg of ethanol, dispersed evenly, and left to stand for 30min, then 8kg of carboxymethyl chitosan was added, and the mixture was heated to an ultrasonic frequency of 22kHz, power Ultrasonic treatment 30min under 100W, obtains material I;

[0030] (3) material 1, 25kg fluorocarbon resin and 10kg tung oil are joined in the high-speed mixer, after mixing 10min, add 10kg hydrogenated castor oil and 3kg oxidized polyethylene wax, then be warming up to 100-110 DEG C and mix 15min, after cooling down get material II;

[0031] (4) 13kg of zeolite powder and 6kg of copper oxide powder were uniformly dispersed in 120kg of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com