Cuprous oxide based heterojunction solar cell and preparation method thereof

A solar cell, cuprous oxide-based technology, applied in the field of solar cells, can solve problems such as energy band mismatch, low photoelectric conversion efficiency, easy to produce interface recombination, etc., to achieve lower product cost, broad application prospects, and abundant storage capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

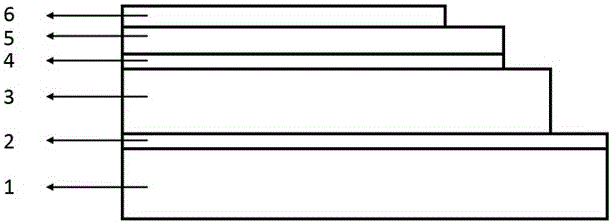

[0024] 1) Use ordinary quartz glass as the substrate 1, ultrasonically clean it in acetone, ethanol, and deionized water for 15 minutes, and use N 2 blow dry.

[0025] 2) 8 nm of metallic chromium as an adhesion layer and 100 nm of metallic gold as a bottom electrode were sequentially deposited on the substrate 1 by electron beam evaporation to obtain a chromium-gold composite electrode 2 .

[0026] 3) The P-type cuprous oxide layer 3 is grown on the above-mentioned chromium-gold composite electrode 2 by the electrochemical deposition method. The specific method is: use the three-electrode method to prepare 0.2mol / L CuSO 4 and 3mol / L lactic acid aqueous solution, adjust the pH value to 12.5 with 2mol / L NaOH solution. The quartz glass deposited with the chromium-gold composite electrode 2 in step (2) was used as the working electrode, and the Ag / AgCl reference electrode and the platinum counter electrode were used to deposit at 40°C for 1 hour by constant potential method to o...

Embodiment 2

[0032] 1) Use ordinary quartz glass as the substrate 1, ultrasonically clean it in acetone, ethanol, and deionized water for 15 minutes respectively, and use N 2 blow dry.

[0033] 2) 8 nm of metallic chromium as an adhesion layer and 120 nm of metallic gold as a bottom electrode were sequentially deposited on the substrate 1 by electron beam evaporation to obtain a chromium-gold composite electrode 2 .

[0034]3) The P-type cuprous oxide layer 3 is grown on the above-mentioned chromium-gold composite electrode 2 by the electrochemical deposition method. The specific method is: use the three-electrode method to prepare 0.2mol / L CuSO 4 and 3mol / L lactic acid aqueous solution, adjust the pH value to 12.8 with 2mol / L NaOH solution. The quartz glass deposited with the chromium-gold composite electrode 2 in step (2) was used as the working electrode, and the Ag / AgCl reference electrode and the platinum counter electrode were used to deposit at 40°C for 1 hour by constant potential...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com