Method for improving surface wetting property of thin polymer film through surface grafting

A polymer film and wetting performance technology, which is applied in the field of improving film wettability and improving the surface wetting performance of polymer films by grafting hydrophilic polymers on the surface, which can solve the problem of poor surface modification effect and poor wetting performance. , poor durability and stability, etc., to achieve the effect of good wetting performance, strong stability, and strong bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

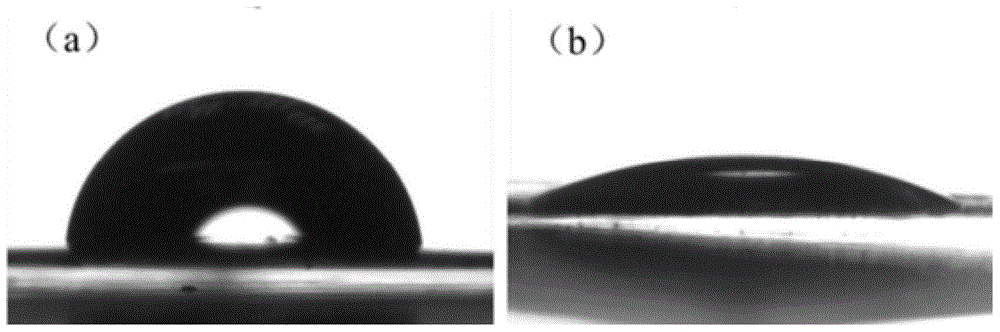

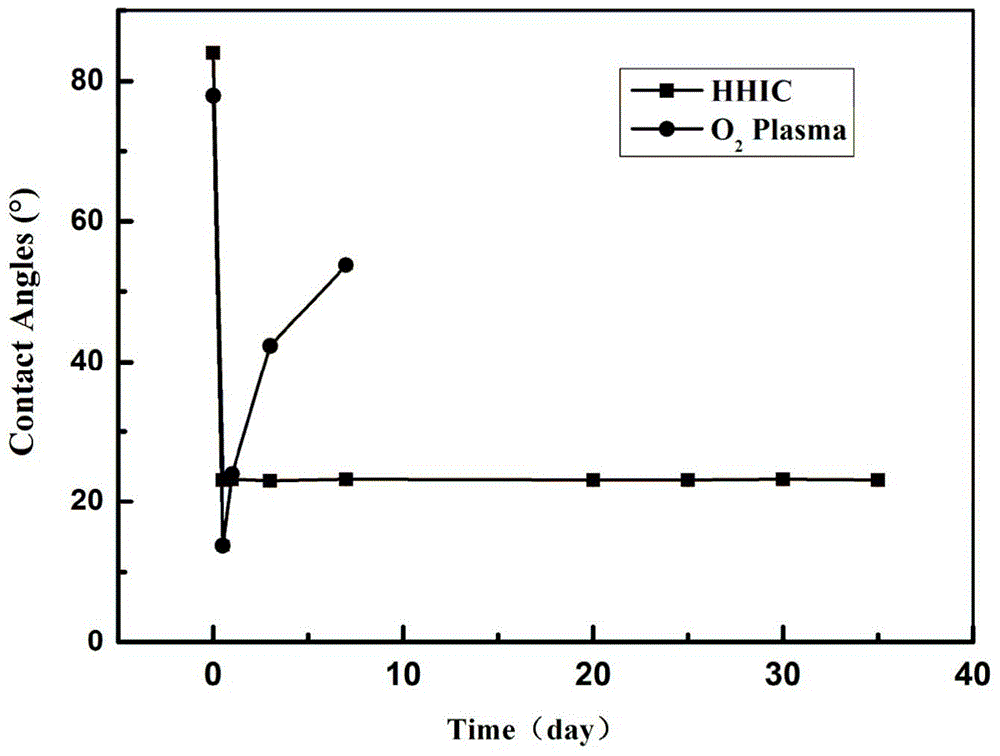

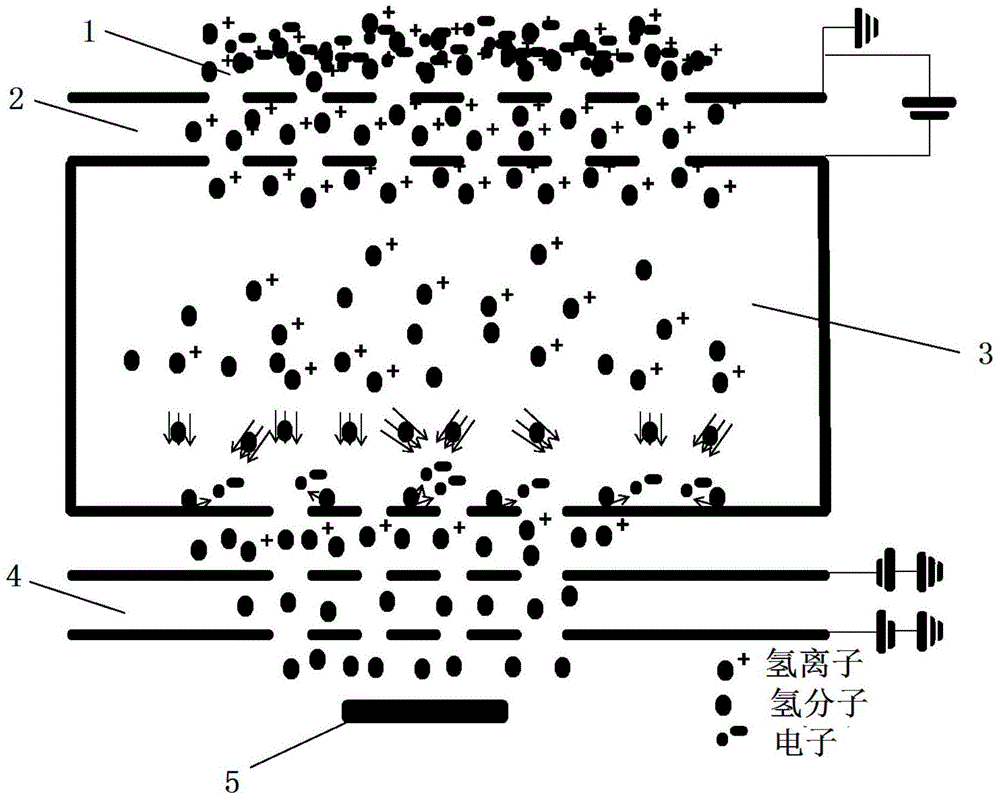

[0046] Spin-coat a layer of hydrophilic polyacrylic acid polymer on the surface of a polychlorinated p-xylylene film with a thickness of 100 μm at a concentration of 5 mg / mL, and dry it for later use. Fix the coated film on the sample stage of the superthermal hydrogen system, turn on the vacuum pump, and make the vacuum degree in the cavity reach 2×10 -2 When Pa, 14SCCM hydrogen gas (standard milliliters / min, the same below) is fed in sequence, and the microwave plasma is turned on, and the acceleration power supply and the repulsion power supply are turned on, wherein the microwave power is 300W, the acceleration voltage is 100V, and the kinetic energy of neutral hydrogen molecules is 10eV. Hydrogen gas bombarded the film sample for 15s, so that polyacrylic acid was cross-linked and fixed on the surface of the polymer film in the form of chemical bonds, and a film with enhanced surface wettability was obtained. The wettability of the film was tested by the surface water conta...

Embodiment 2

[0048] The polychlorinated p-xylylene film (thickness 100 μm) was ultrasonically cleaned for 15 min in containers containing acetone and ethanol, and dried with nitrogen. Spin-coat a layer of hydrophilic polyethylene glycol polymer on the surface of the clean polymer film, the concentration of the hydrophilic polymer is 8mg / mL, and dry it for later use. Mount the coated film on the sample stage of the epithermal system. Turn on the vacuum pump to make the vacuum in the cavity reach 5×10 -2 At Pa, 14SCCM hydrogen gas is fed in sequence, and the microwave plasma is turned on, and the acceleration power supply and the repulsion power supply are turned on. The microwave power is 300W, the acceleration voltage is 100V, the kinetic energy of neutral hydrogen molecules is 15eV, and the film sample is bombarded with hydrogen for 30s. Polyethylene glycol is cross-linked and fixed on the surface of the polymer film in the form of chemical bonds to obtain a film with enhanced surface we...

Embodiment 3

[0050] The polychlorinated p-xylylene film (thickness 100 μm) was ultrasonically cleaned for 15 min in containers containing acetone and ethanol, and dried with nitrogen. Spin-coat a layer of hydrophilic polyacrylic acid polymer on the surface of the clean polymer film, the concentration of the hydrophilic polymer is 10mg / mL, and dry it for later use. Mount the coated film on the sample stage of the epithermal system. Turn on the vacuum pump to make the vacuum in the cavity reach 6×10 -2 At Pa, 14SCCM hydrogen gas is fed in sequence, and the microwave plasma is turned on, and the acceleration power supply and the repulsion power supply are turned on. The microwave power is 300W, the acceleration voltage is 100V, the kinetic energy of neutral hydrogen molecules is 16eV, and the film sample is bombarded with hydrogen for 60s. Polyacrylic acid is cross-linked and fixed on the surface of the polymer film in the form of chemical bonds to obtain a film with enhanced surface wettabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com