Method for preparing protein films by improving enzyme-promoting crosslinking modification of gluten proteins through multi-primary amide

A gluten protein and compound technology, applied in flexible coverings, packaging, wrapping paper, etc., can solve the problems of lack of lysine, limited physical and mechanical properties of gluten materials, and low number of free amino groups, etc. Mild conditions, environmentally friendly and easy to control, efficient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

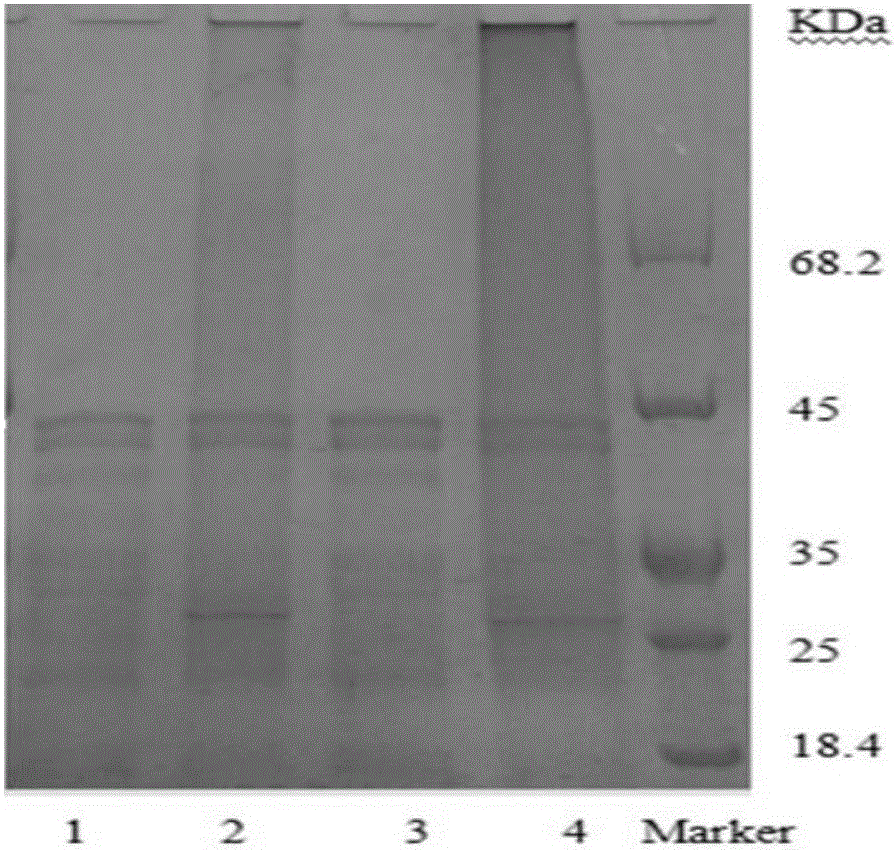

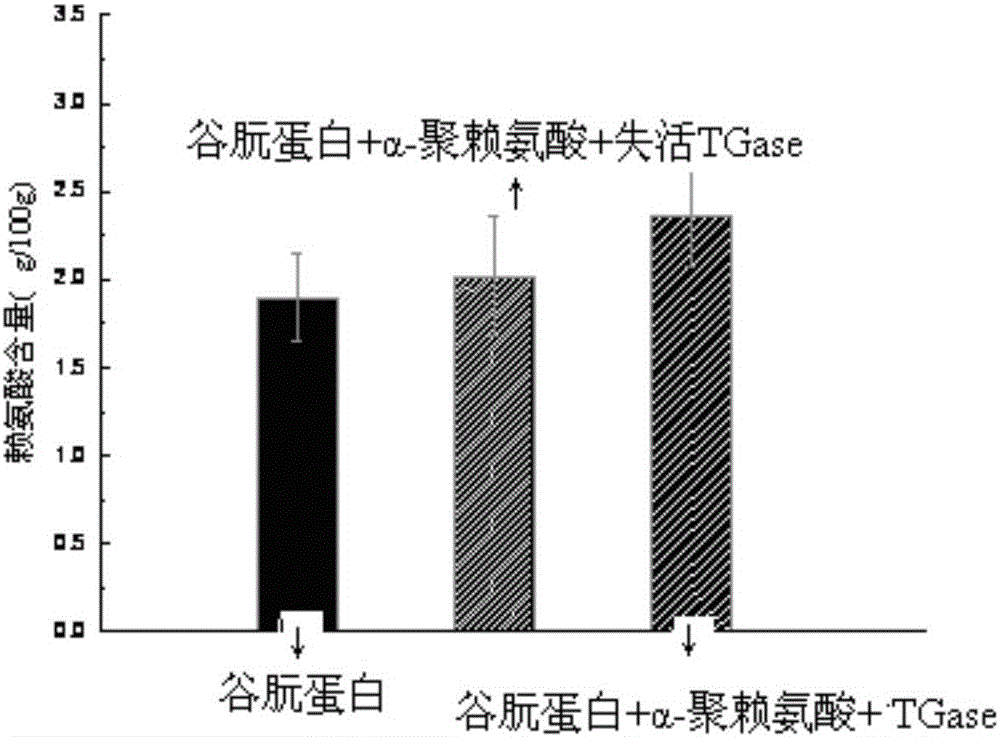

[0015] Example 1 α-polylysine improves the activity of TGase in catalyzing the cross-linking reaction of gluten protein

[0016] Weigh the gluten protein and dissolve it in phosphate buffer (pH=7.0), the concentration is 3%, add a certain amount of α-polylysine, after the gluten protein is evenly dispersed in the solution, add a certain amount of transglutaminase (TGase), about 15u / g albumen, (the TGase that the present invention uses is widely present in plant, animal and microorganism, and the TGase of any source can realize identical effect in the present invention, and the TGase of different sources is all to gluten protein Catalyzed), reacted at 37°C for 3 hours under constant temperature stirring. Inactivated enzyme was added to the control sample, and the other conditions were the same. After the reaction was finished, it was freeze-dried and set aside. Before lyophilization, perform characterization tests. Get a certain amount of dispersion after the reaction, centr...

Embodiment 2

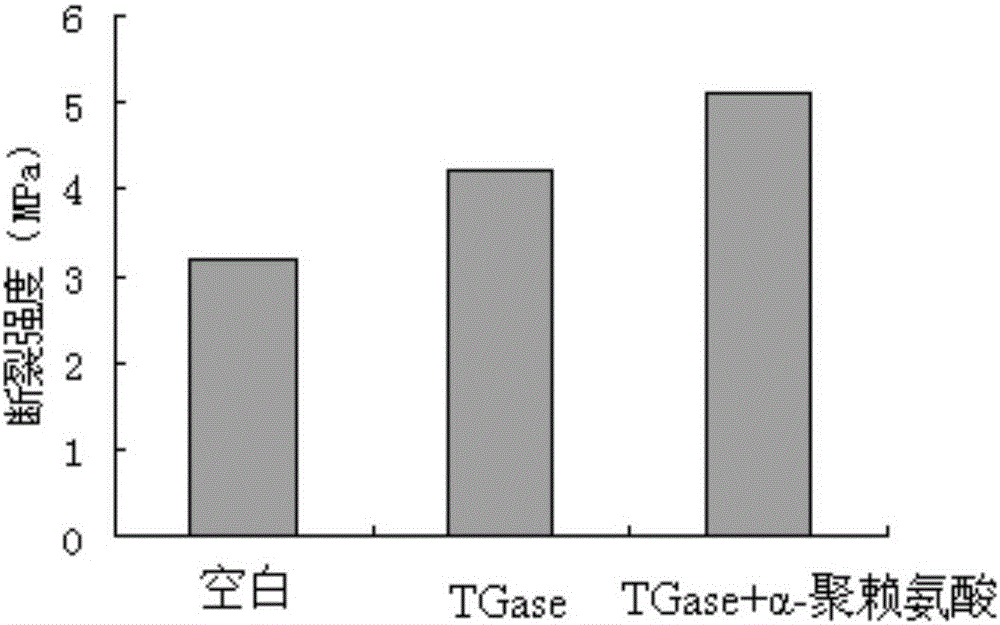

[0017] Modified gluten protein film after embodiment 2

[0018] Weigh the gluten protein and dissolve it in phosphate buffer (pH=7.0), the concentration is 3%, add a certain amount of α-polylysine, after the gluten protein is evenly dispersed in the solution, add a certain amount of transglutaminase (TGase), about 15u / g protein, reacted at 37°C for 3 hours under constant stirring. Inactivated enzyme was added to the control sample, and the other conditions were the same. After the reaction was finished, it was freeze-dried and set aside. Dissolve the modified gluten protein in formic acid, add a certain amount of glycerin, and stir at 40°C for 3 hours. After fully dissolving, place it in an ultrasonic oscillator for 5 minutes to remove internal air bubbles. The solution was poured onto a smooth polytetrafluoroethylene plate, dried at room temperature, and then the dried film was carefully peeled off from the plate to prepare a modified gluten film. The physical and mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com