PH-responsive sodium alginate nano gel and production method thereof

A technology of sodium alginate and nanogel, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, aerosol delivery, etc. It can solve the problems of poor quality reliability, low output, high cost, etc., and reach the size of the gel Controllable, simple preparation process, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

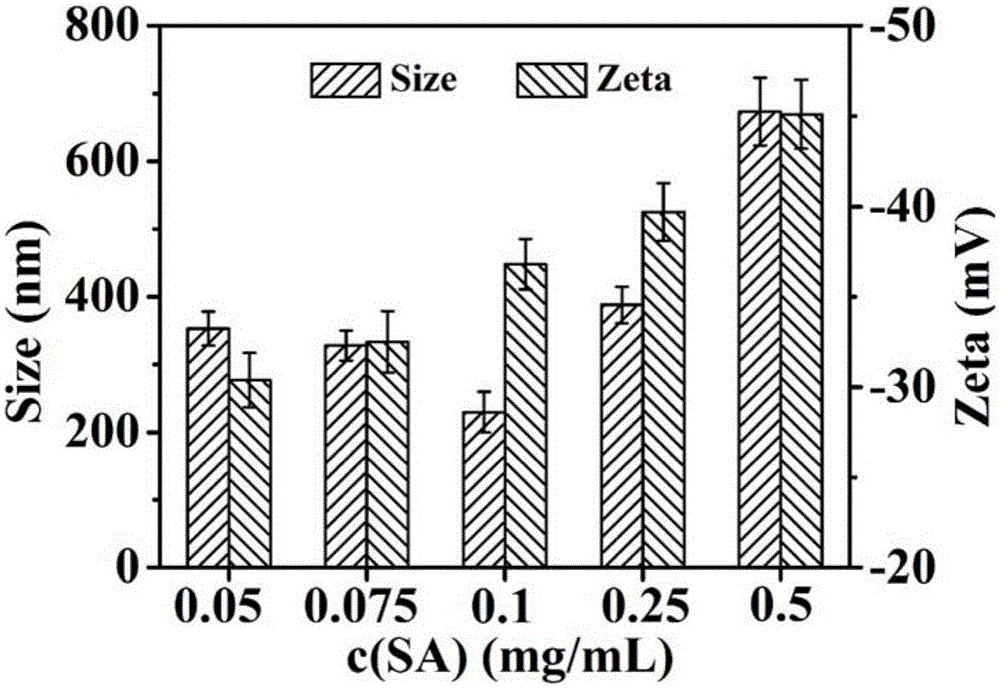

[0028] In a three-neck flask, add 0.2mL 5mg / mL sodium alginate aqueous solution, dilute it with ultrapure water, and stir for 0.5h; then, under ultrasonic conditions, slowly add 0.225mL 0.01mol / L calcium chloride solution dropwise solution, dilute to a final volume of 20.0 mL with ultrapure water, and stir for 2 h. The obtained crude product solution was dialyzed four times in ultrapure water, and the molecular weight cut-off of the dialysis bag used was 10KDa to obtain an aqueous solution of nanogel, which was freeze-dried to obtain flocculent sodium alginate nanogel.

[0029] The average particle size and potential of the obtained nanogels are as figure 1 As shown, they are 350-375nm and -31.2mV respectively.

Embodiment 2

[0031] In a three-neck flask, add 0.2mL 5mg / mL sodium alginate aqueous solution, dilute it with ultrapure water, and stir for 0.5h; then, under ultrasonic conditions, slowly add 0.225mL 0.01mol / L calcium chloride solution dropwise solution, dilute to a final volume of 13.3 mL with ultrapure water, and stir for 2 h. The obtained crude product solution was dialyzed four times in ultrapure water, and the molecular weight cut-off of the dialysis bag used was 10KDa to obtain an aqueous solution of nanogel, which was freeze-dried to obtain flocculent sodium alginate nanogel.

[0032] The average particle size and potential of the obtained nanogels are as figure 1 As shown, they are 300-355nm and -34.2mV respectively.

Embodiment 3

[0034] In the three-neck flask, add 0.4mL 5mg / mL sodium alginate aqueous solution, dilute it with ultrapure water, and stir for 0.5h; then, under ultrasonic conditions, slowly add 0.45mL 0.01mol / L calcium chloride solution dropwise solution, dilute to a final volume of 20.0 mL with ultrapure water, and stir for 2 h. The obtained crude product solution was dialyzed four times in ultrapure water, and the molecular weight cut-off of the dialysis bag used was 10KDa to obtain an aqueous solution of nanogel, which was freeze-dried to obtain flocculent sodium alginate nanogel.

[0035] The average particle size and potential of the obtained nanogels are as figure 1 As shown, they are 170-210nm and -37.2mV respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com