A kind of preparation method of carboxylated nanocrystalline cellulose reinforced calcium phosphate scaffold

A nanocrystal, carboxylation technology, applied in the direction of prosthesis, medical science, etc., can solve the incompatibility of mechanical strength, biocompatibility and biodegradability, increase the probability of infection in patients, the pain of secondary surgery and economic burden, It is difficult to obtain monodisperse fibers, etc., to achieve the effects of good biodegradability, avoidance of damage and burden, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of carboxylated nanocrystalline cellulose reinforced calcium phosphate scaffold, the steps are:

[0049] A. Nanocrystalline cellulose carboxylation modification

[0050] A1, adding nanocrystalline cellulose to deionized water to prepare a suspension of nanocrystalline cellulose with a concentration of 1wt.%.

[0051] A2. Add 0.18 parts by weight of NaBr and 0.07 parts by weight of 2,2,6,6-tetramethylpiperidine-1-oxide to 100 parts by weight of nanocrystalline cellulose suspension. After stirring and dissolving, add 40 The concentration of part weight is the NaClO solution of 12wt.% and constantly stirs, adjusts the pH value of solution with the NaOH solution of 0.5mol / L in the stirring process, makes pH value stable at 10.5; Then adds 40 parts of heavy dehydrated alcohol, obtains Dispersions;

[0052] A3. Adjust the pH value of the dispersion in step A2 to 3.0 with 0.5 mol / L HCl, and let it stand for 24 hours; centrifuge, wash and use a dialysis b...

Embodiment 2

[0072] A preparation method of carboxylated nanocrystalline cellulose reinforced calcium phosphate scaffold, the steps are:

[0073] A. Nanocrystalline cellulose carboxylation modification

[0074] A1, adding nanocrystalline cellulose to deionized water to prepare a suspension of nanocrystalline cellulose with a concentration of 0.5wt.%.

[0075] A2, add 0.1 part by weight of NaBr and 0.01 part by weight of 2,2,6,6-tetramethylpiperidine-1-oxide to 100 parts by weight of nanocrystalline cellulose suspension, stir and dissolve, then add 10 The concentration of part weight is 5wt.% NaClO solution and is constantly stirred, and the pH value of solution is adjusted with the KOH solution of 0.1mol / L in the stirring process, makes pH value be stable at 9.0; Then add 10 parts of heavy dehydrated alcohol, obtain Dispersions;

[0076] A3, use 0.1mol / L of H 2 SO 4 Solution Adjust the pH value of the dispersion in step A2 to 2.5, and let it stand for 36 hours; centrifuge, wash, and use ...

Embodiment 3

[0084] A preparation method of carboxylated nanocrystalline cellulose reinforced calcium phosphate scaffold, the steps are:

[0085] A. Nanocrystalline cellulose carboxylation modification

[0086] A1, adding nanocrystalline cellulose to deionized water to prepare a suspension of nanocrystalline cellulose with a concentration of 5wt.%.

[0087] A2. Add 10 parts by weight of NaBr and 0.5 parts by weight of 2,2,6,6-tetramethylpiperidine-1-oxide to 100 parts by weight of nanocrystalline cellulose suspension, stir and dissolve, then add 60 The concentration of part weight is the NaClO solution of 14wt.% and is constantly stirred, and the pH value of solution is adjusted with the NaOH solution of 1mol / L in the stirring process, makes pH value be stable at 11.5; liquid;

[0088] A3. Use 1.0mol / L HCl to adjust the pH value of the dispersion in step A2 to 3.0, and let it stand for 24h; centrifuge, wash and use a dialysis bag to filter out small molecular substances with a molecular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

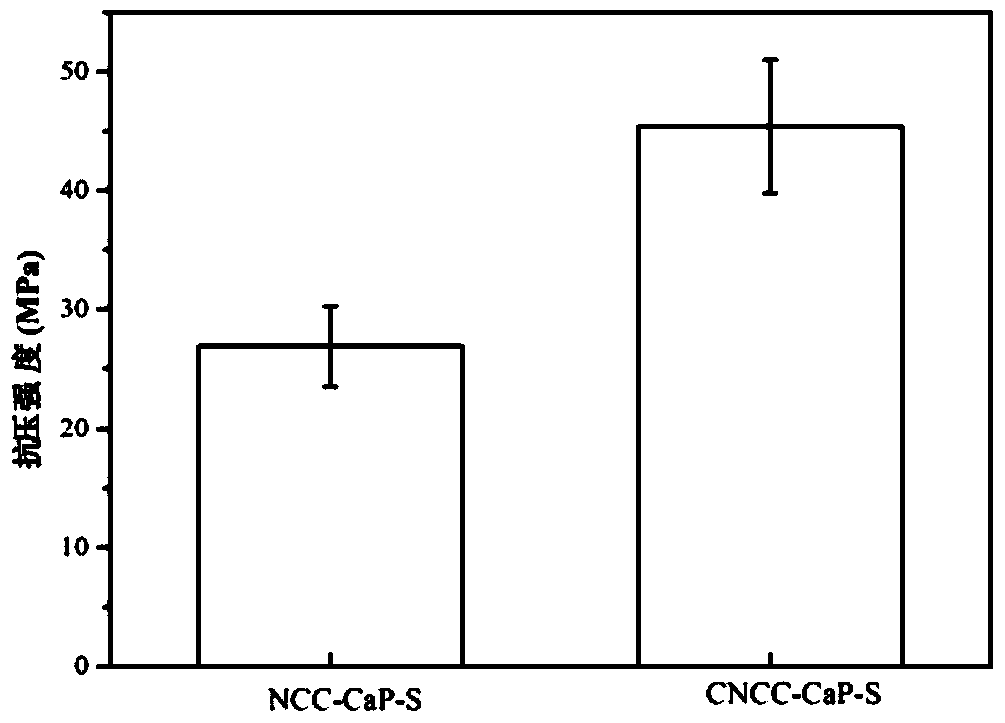

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com