Water-based putty powder

A putty powder, water-based technology, applied in the field of water-based putty powder, can solve the problems of poor adhesion and mildew resistance, harmful to human body, easy to mildew, etc., to improve brightness and fineness, enhance filling power, and prevent mildew. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

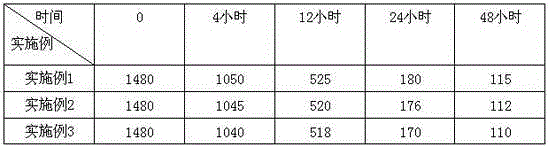

Examples

Embodiment 1

[0024] The raw material that this embodiment adopts is:

[0025] 40 parts of modified talcum powder, 40 parts of lime calcium powder, 12 parts of white cement, 12 parts of dihydrate silicon dioxide powder, 1.5 parts of carboxymethyl cellulose, 10 parts of activated carbon, 2 parts of rubber powder, 0.1 part of triclosan, 0.5 parts of pigment, wherein the rubber powder is redispersible latex powder, and the pigment is green;

[0026] The preparation method is:

[0027] Add activated carbon, ash calcium powder, silicon dioxide dihydrate, modified talc powder and white cement in turn to the mixer, stir for 20 minutes and mix evenly, then add carboxymethylcellulose, rubber powder, pigment and triclosan in turn. In the blender, continue to stir for 10 minutes to make it fully mixed, that is, ready.

Embodiment 2

[0029] The raw material that this embodiment adopts is:

[0030] 60 parts of modified talcum powder, 20 parts of lime calcium powder, 10 parts of white cement, 15 parts of dihydrate silicon dioxide powder, 2.0 parts of carboxymethyl cellulose, 12 parts of activated carbon, 3 parts of rubber powder, 0.2 part of triclosan, 1 part of pigment;

[0031] Among them, the rubber powder is polyvinyl alcohol rubber powder, and the raw material is red;

[0032] Its preparation method is identical with embodiment 1.

Embodiment 3

[0034] The raw material that this embodiment adopts is:

[0035] 50 parts of modified talcum powder, 30 parts of lime calcium powder, 15 parts of white cement, 13 parts of dihydrate silicon dioxide powder, 2.5 parts of carboxymethyl cellulose, 15 parts of activated carbon, 3 parts of rubber powder, 0.3 part of triclosan, 0.5 parts of pigment;

[0036] Among them, the rubber powder is acrylic resin, and the color is yellow;

[0037] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com