Silk fibroin microspheres loaded with arbutin and vitamin C, preparation method and application thereof

A silk fibroin microsphere and silk fibroin technology, applied in the field of protein microsphere preparation, can solve the problems of low transdermal absorption rate, insignificant whitening effect, and inability to directly apply arbutin and vitamin C to the skin, etc. Achieve the effect of promoting metabolism, increasing transdermal absorption, and solving poor transdermal absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

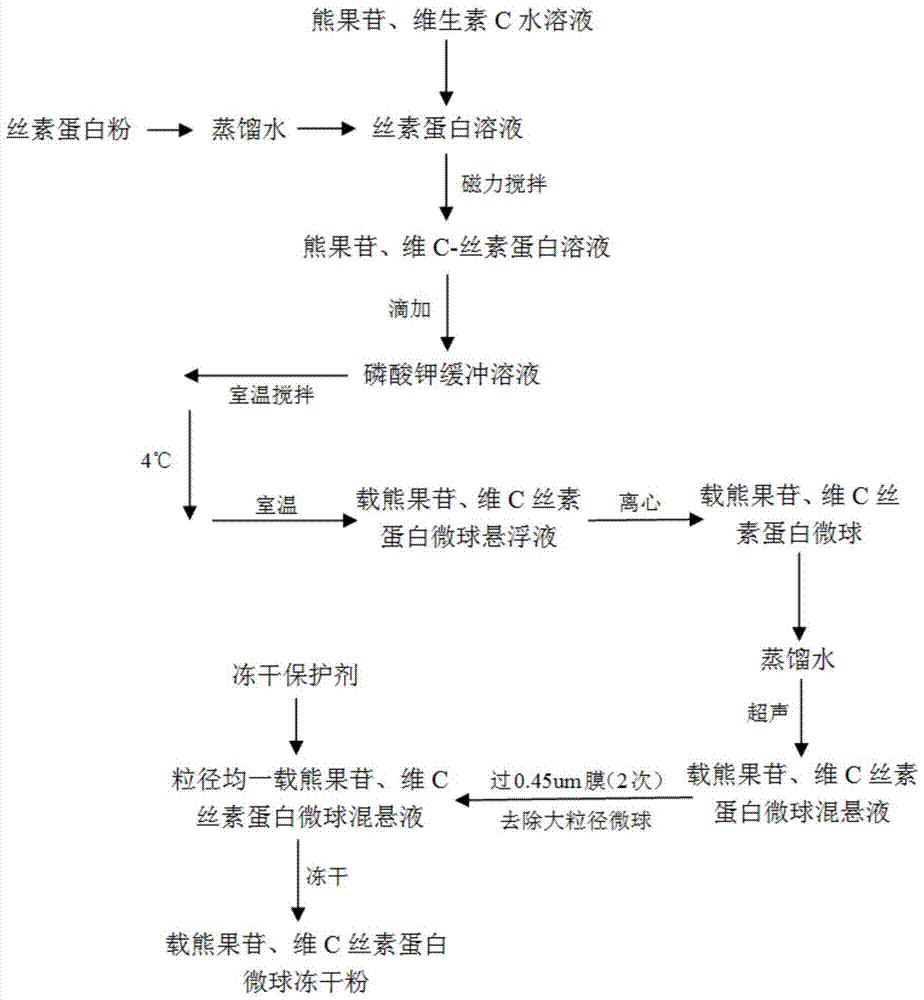

[0037] The present invention also provides a method for preparing the aforementioned silk fibroin microspheres loaded with arbutin and vitamin C, comprising the following steps:

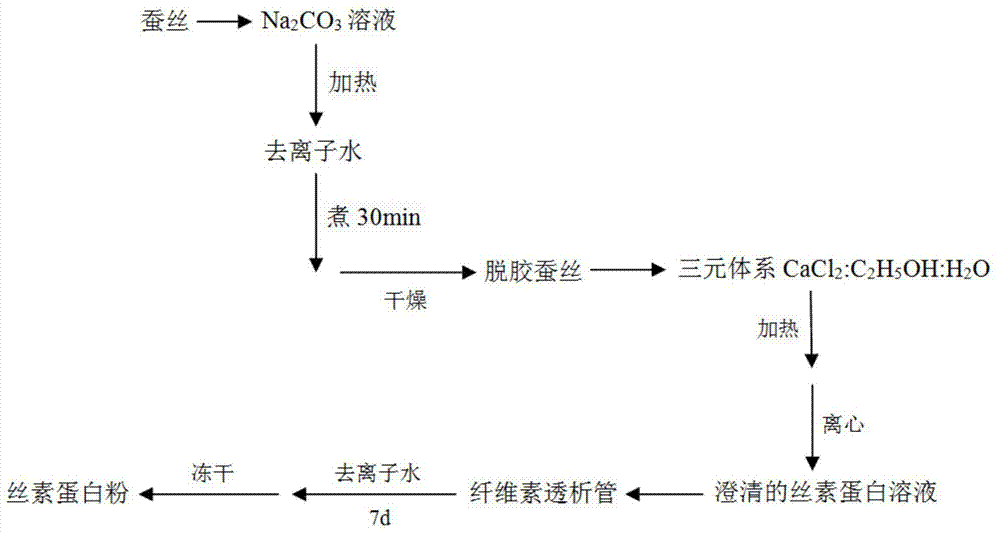

[0038] Step 1, prepare silk fibroin:

[0039]Step 1-1, according to the mass ratio of silk and 0.01~0.1mol / L sodium carbonate solution is 1:10~1:5, add silk into the sodium carbonate solution of 100 ℃, heat for 20~30min and then put Boil in deionized water at 90-100°C for 30 minutes, and vacuum dry the boiled silk at 35°C for 20 minutes to obtain degummed silk;

[0040] Step 1-2, add degummed silk to the ternary system CaCl 2 :C 2 H 5 OH:H 2 O, incubate at 70-80 °C for 2 h, and then at a centrifugal force of 1.35 × 10 4 Centrifuge at g for 8-10 min to obtain a silk fibroin solution;

[0041] Step 1-3, put the silk fibroin solution into a cellulose dialysis tube and dialyze it in deionized water at 4 °C for 7 days. After the dialyzed silk fibroin solution is pre-frozen at -80 °C for 15 hours, it...

Embodiment 1

[0056] In the present embodiment, a silk fibroin microsphere containing arbutin and vitamin C is prepared, and the preparation method is as follows:

[0057] Step 1, Preparation of Silk Fibroin

[0058] Step 1-1, add 30.00g of silk into 100mL of 0.02mol / L sodium carbonate solution at 100°C, heat it for 25min, then boil it in deionized water at 95°C for 30min, and vacuum dry the boiled silk at 35°C for 20min, Obtain degummed silk.

[0059] Step 1-2, add degummed silk to the ternary system CaCl 2 :C 2 H 5 OH:H 2 O, CaCl 2 , C 2 H 5 OH, H 2 The molar ratio of O was 1:2:8, and the temperature was kept at 75 °C for 2 h, and then the centrifugal force was 1.35 × 10 4 Centrifuge at g for 9 min to obtain a silk fibroin solution.

[0060] Steps 1-3, put the silk fibroin solution into a cellulose dialysis tube and dialyze it in deionized water at 4 °C for 7 days. After the dialyzed silk fibroin solution is pre-frozen at -80 °C for 15 hours, it is placed in a vacuum with a vacu...

Embodiment 2

[0075] In the present embodiment, a silk fibroin microsphere containing arbutin and vitamin C is prepared, and the preparation method is as follows:

[0076] Step 1, Preparation of Silk Fibroin

[0077] Step 1-1, add 50.00g of silk into 500mL of 0.1mol / L sodium carbonate solution at 100°C, heat for 30min, then boil in deionized water at 100°C for 30min, and vacuum dry the boiled silk at 35°C for 20min, Obtain degummed silk.

[0078] Step 1-2, add degummed silk to the ternary system CaCl 2 :C 2 H 5 OH:H 2 O, CaCl 2 , C 2 H 5 OH, H 2 The molar ratio of O was 1:2:8, and the temperature was kept at 80 °C for 2 h, and then the centrifugal force was 1.35 × 10 4 Centrifuge at g for 10 min to obtain a silk fibroin solution.

[0079] Steps 1-3, put the silk fibroin solution into a cellulose dialysis tube and dialyze it in deionized water at 4 °C for 7 days. After the dialyzed silk fibroin solution is pre-frozen at -80 °C for 15 hours, it is placed in a vacuum with a vacuum de...

PUM

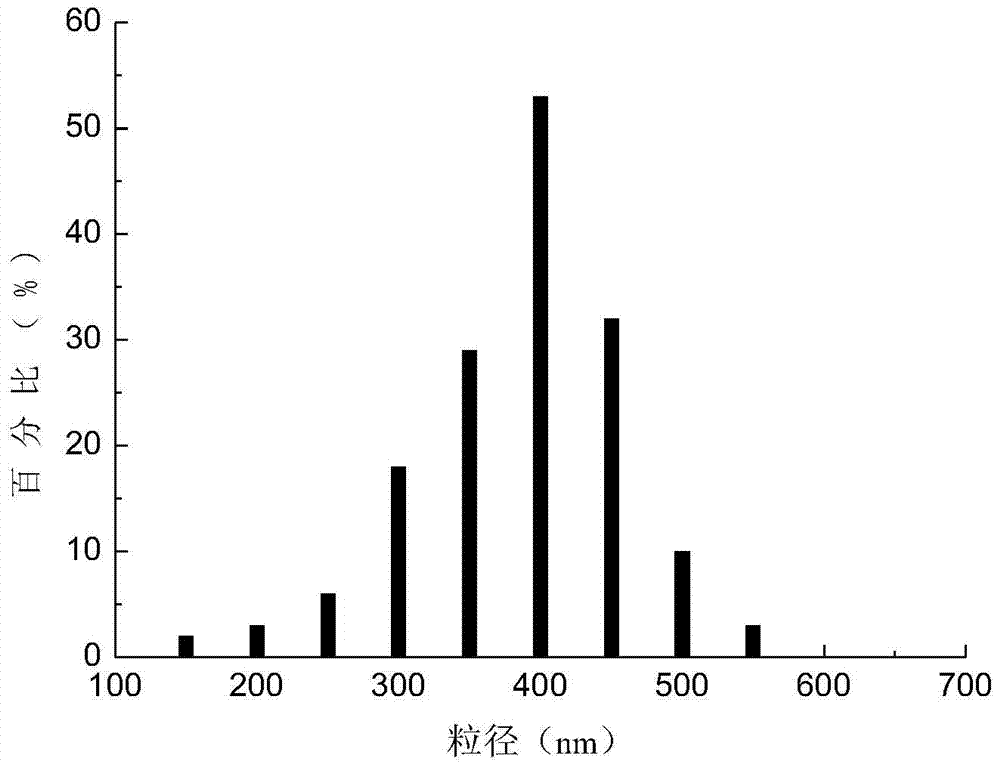

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com