Moxifloxacin hydrochloride film-coated tablet and preparation method thereof

A technology of moxifloxacin hydrochloride and film-coated tablets, applied in sugar-coated pills, pill delivery, antibacterial drugs and other directions, can solve the problems of poor water solubility, affected safety, difficult to granulate, etc., and achieves easy operation and pharmaceutical excipients. Few, simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Moxifloxacin hydrochloride film-coated tablet

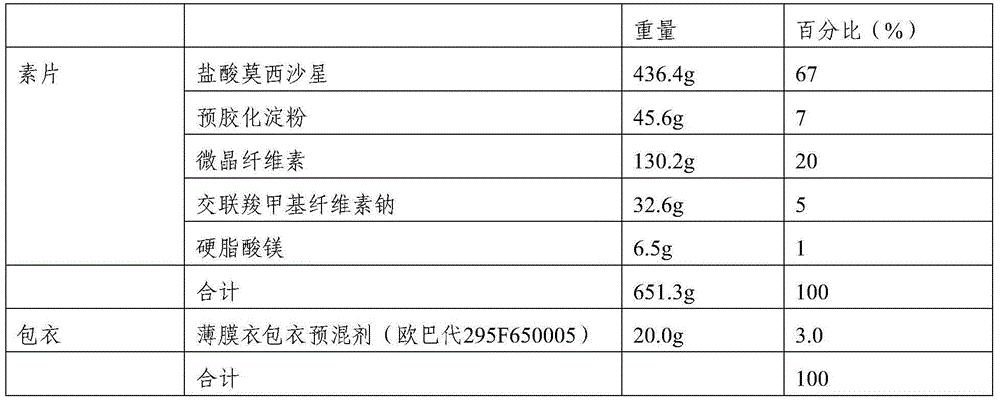

[0035] 1. Composition: The film-coated tablet is calculated by weight percentage, and the prescription of 1000 tablets (calculated on the basis of uncoated tablet) is as follows:

[0036]

[0037] 2. Preparation process:

[0038] (1) The raw and auxiliary materials are processed through an 80-mesh sieve;

[0039] (2) Wet mixing and granulation: Moxifloxacin hydrochloride, microcrystalline cellulose, pregelatinized starch, and croscarmellose sodium that have been sieved are put into a wet granulator and stirred at high speed, and microcrystalline Purified water with twice the volume of the cellulose prescription is used to make wet granules with a 20-mesh screen in a swing granulator, and the wet granules are dried in a hot air circulation oven at 55°C until the moisture is less than 3%;

[0040] (3) Tablet compression: dry granules are mixed with sieved magnesium stearate, put into a motion mixer for mix...

Embodiment 2

[0042] Embodiment 2: Moxifloxacin hydrochloride film-coated tablet

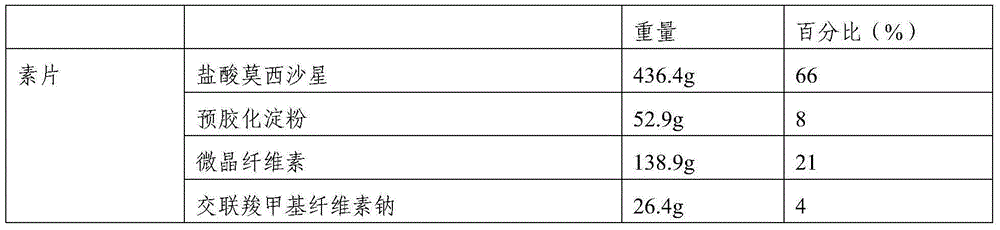

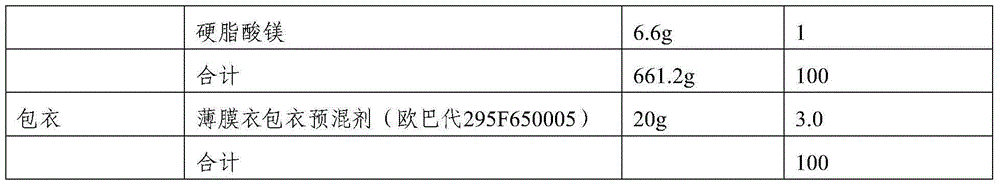

[0043] 1. Composition: The film-coated tablet is calculated by weight percentage, and the prescription of 1000 tablets (calculated on the basis of uncoated tablet) is as follows:

[0044]

[0045]

[0046] 2. Preparation process:

[0047] (1) The raw and auxiliary materials are processed through an 80-mesh sieve;

[0048] (2) Wet mixing and granulation: Moxifloxacin hydrochloride, microcrystalline cellulose, pregelatinized starch, and croscarmellose sodium that have been sieved are put into a wet granulator and stirred at high speed, and microcrystalline Purified water with twice the volume of the cellulose prescription is used to make wet granules with a 20-mesh screen in a swing granulator, and the wet granules are dried in a hot air circulation oven at 50°C until the moisture is less than 4%;

[0049] (3) Tablet compression: dry granules are mixed with sieved magnesium stearate, put into a motion mix...

Embodiment 3

[0051] Embodiment 3: Moxifloxacin hydrochloride film-coated tablet

[0052] 1. Composition: The film-coated tablet is calculated by weight percentage, and the prescription of 1000 tablets (calculated on the basis of uncoated tablet) is as follows:

[0053]

[0054] 2. Preparation process:

[0055] (1) The raw and auxiliary materials are processed through an 80-mesh sieve;

[0056] (2) Wet mixing and granulation: Moxifloxacin hydrochloride, microcrystalline cellulose, pregelatinized starch, and croscarmellose sodium that have been sieved are put into a wet granulator and stirred at high speed, and microcrystalline Purified water with twice the volume of the cellulose prescription is used to make wet granules with a 20-mesh screen in a swing granulator, and the wet granules are dried in a hot air circulation oven at 60°C until the moisture is less than 2%;

[0057] (3) Tablet compression: dry granules are mixed with sieved magnesium stearate, put into a motion mixer for mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com