Flue gas integration removal system and method by means of gas-like phase preoxidation combining with absorption

A pre-oxidation, gas-phase technology, applied in the field of flue gas purification, can solve problems such as failure to meet emission standards, low removal efficiency, chloride ion corrosion, etc., achieve good environmental and economic benefits, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Preparation of liquid-phase composite oxidant mother liquor: wherein the concentration %wt ratio of hydrogen peroxide and sodium chlorite is 25:1, after mixing the two according to the above concentration ratio, dilute it to the mother liquor concentration with process water, and the pH is 4.5.

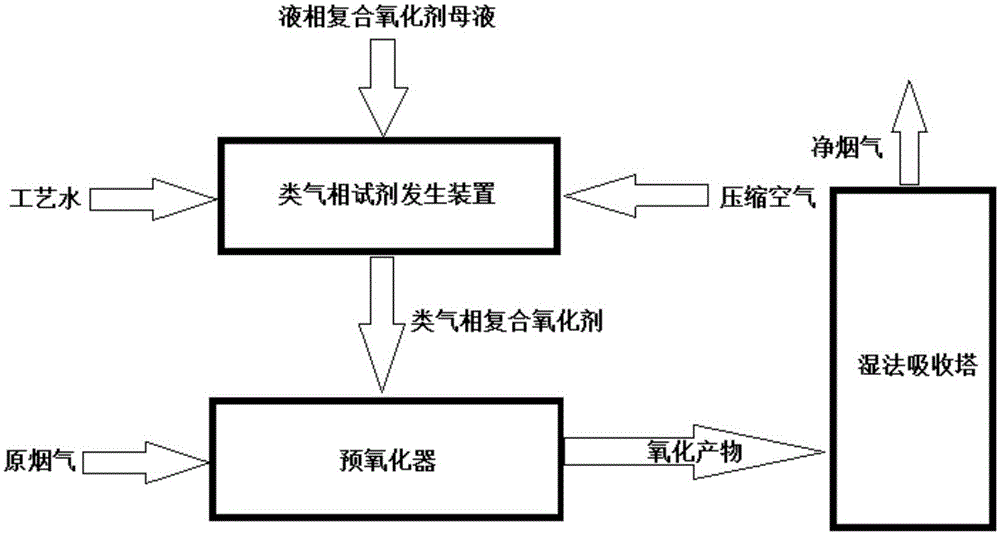

[0093] The above-mentioned liquid-phase composite oxidant is injected into the gas-phase reagent generating device, and after passing through the pre-oxidizer and the wet absorption tower, the integrated desulfurization, denitrification and demercuration are realized. The reaction conditions are shown in Table 2.

[0094] Table 2 Reaction Conditions

[0095] condition

[0096] According to the above conditions, the flue gas is desulfurized, demercurized and denitrified, and it is detected that: SO 2 The removal efficiency is 99%, the denitrification efficiency is 90.5%, and the mercury removal efficiency is over 92.7%.

Embodiment 2

[0098] Preparation of composite oxidant: wherein the concentration %wt ratio of hydrogen peroxide and sodium chlorite is 30:0.5, after mixing the two according to the above concentration ratio, dilute it to the mother liquor concentration with process water, and the pH is 5.7.

[0099] The above-mentioned liquid-phase composite oxidant is injected into the gas-phase reagent generating device, and after passing through the pre-oxidizer and the wet absorption tower, the integrated desulfurization, denitrification and demercuration are realized. The reaction conditions are shown in Table 3.

[0100] Table 3 reaction conditions

[0101] condition

[0102] According to the above conditions, the flue gas is desulfurized, demercurized and denitrified, and it is detected that: SO 2 The removal efficiency is 100%, the denitrification efficiency is 89.2%, and the mercury removal efficiency is over 93.3%.

Embodiment 3

[0104] Prepare composite oxidant: the concentration %wt ratio of sodium chlorite and sodium persulfate is 2:4. After mixing the two according to the above concentration ratio, use process water to dilute it to the mother liquor concentration, and the pH is 10.

[0105] The above-mentioned liquid-phase composite oxidant is injected into the gas-phase reagent generating device, and after passing through the pre-oxidizer and the wet absorption tower, the integrated desulfurization, denitrification and demercuration are realized. The reaction conditions are shown in Table 4.

[0106] Table 4 reaction conditions

[0107] condition

[0108] According to the above conditions, the flue gas is desulfurized, demercurized and denitrified, and it is detected that: SO 2 The removal efficiency is 100%, the denitrification efficiency is 92.0%, and the mercury removal efficiency is over 94.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com