Preparation method of load type nano catalyst for catalyzing Suzuki coupling reaction

A nano-catalyst and supported palladium technology, which is applied in the field of catalyst preparation, can solve the problems of particle redistribution and agglomeration, and achieve the effects of small size, avoiding particle redistribution, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

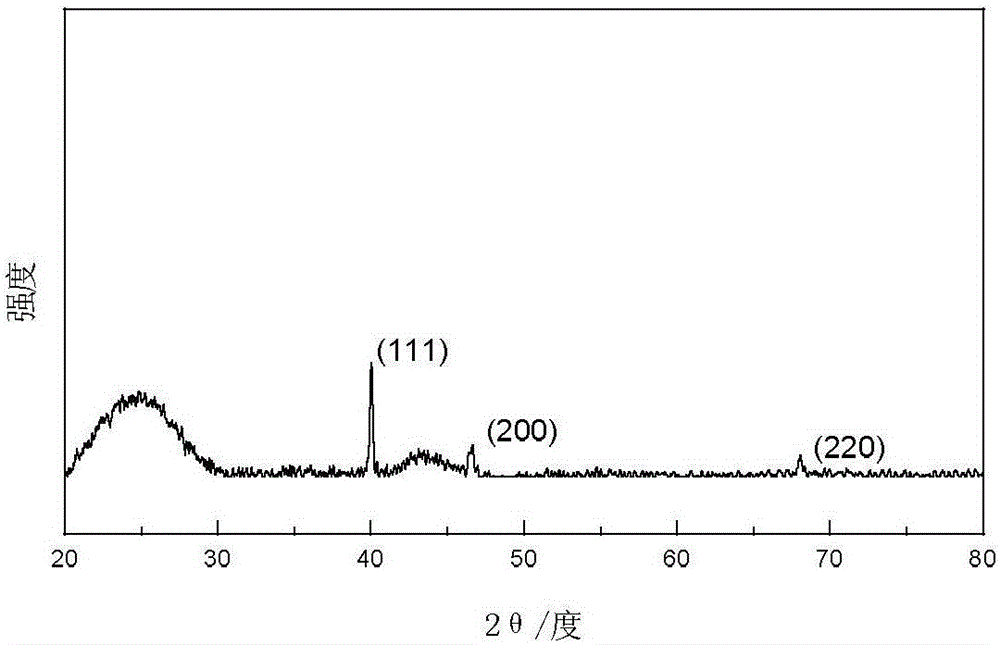

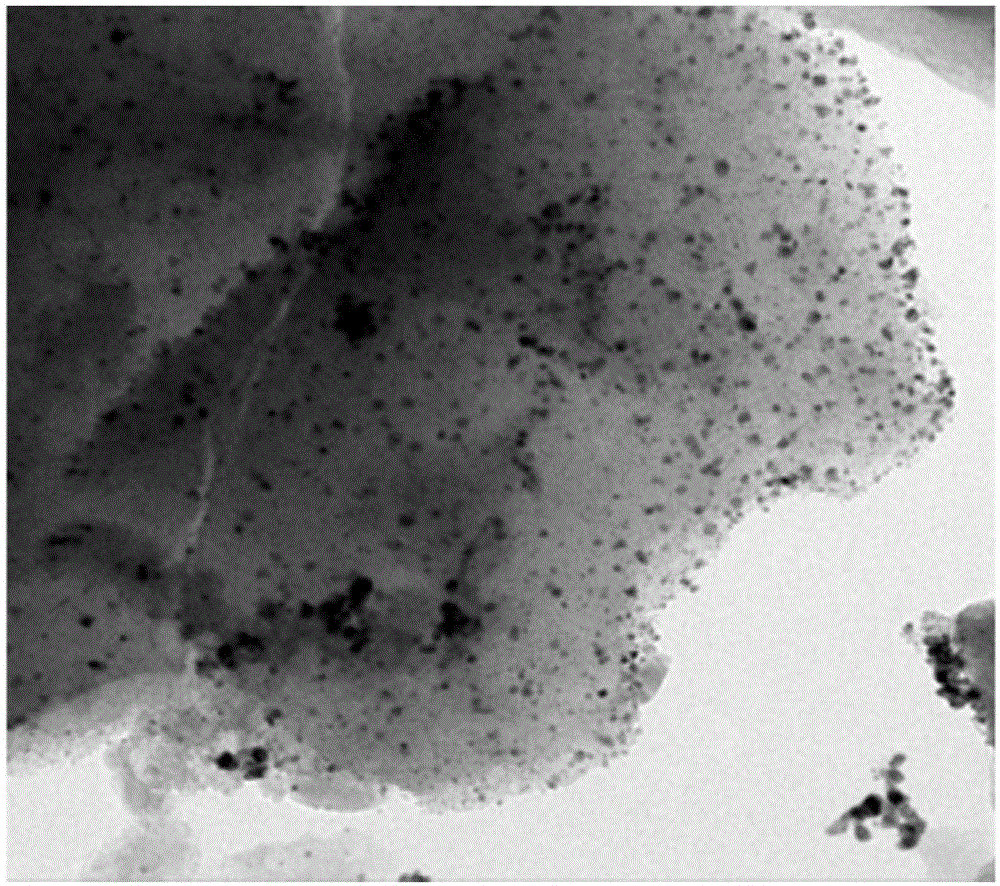

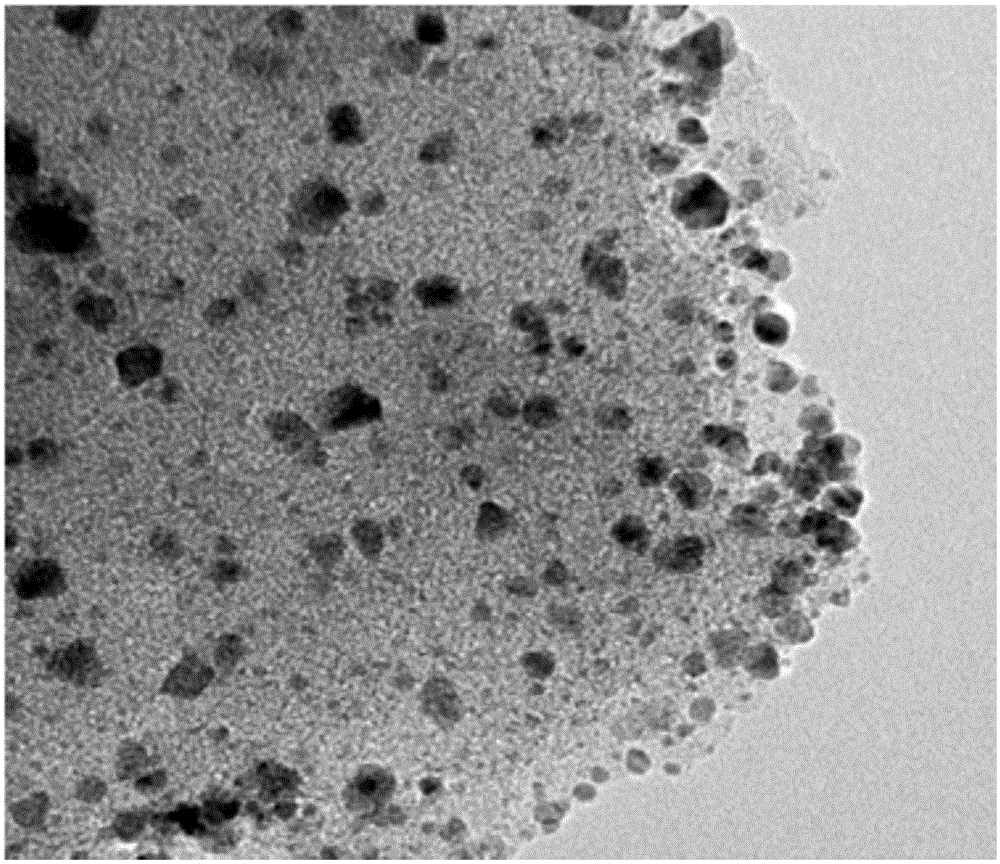

[0014] Specific embodiment one: the preparation method of the loaded palladium nano-catalyst of catalytic Suzuki coupling reaction in the present embodiment is carried out according to the following steps:

[0015] 1. Mix 1g of activated carbon carrier with 2-10ml of 0.0470mol / L Na at room temperature 2 PdCl 4 The solutions were mixed, stirred and impregnated for 12 hours, then centrifuged, and dried at 110°C for 12 hours to obtain a sample;

[0016] 2. Take 0.1g sample evenly spread on the carrier boat, place it in the discharge tube, use the vacuum pump to vacuum the inside of the plasma discharger, and pass it into the N 2 Plasma discharge gas, by adjusting the fine-tuning valve, the gas pressure is kept at 60-120Pa, and high-voltage direct current is applied at both ends of the electrodes, the gas in the discharge tube is broken down, and glow discharge plasma is triggered. The discharge power is 330W-660W, and the discharge time for 5-60min, the Pd 2+ Reduction into a ...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, at room temperature, 1 g of activated carbon carrier and 5 ml of 0.0470mol / L Na 2 PdCl 4 The solution is mixed. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the gas pressure is kept at 70-110 Pa in step 2. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com