Graphene oxide reinforced nylon material and its preparation method and application

A graphene and stone oxide technology, which is applied to graphene oxide reinforced nylon material and its preparation method and application field in 3D printing, can solve the problems of poor interfacial bonding force, poor dispersibility, low regional performance, etc. The effect of strong interface bonding, simple raw material formula, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

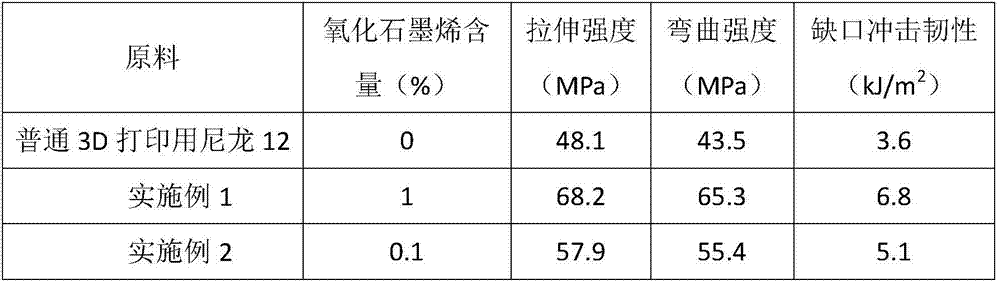

Examples

Embodiment 1

[0037] The graphene oxide reinforced nylon material in this embodiment is composed of the following components and parts by weight: graphene oxide: 0.02 kg, nylon 12: 1.98 kg.

[0038] The preparation method of graphene oxide reinforced nylon material in this embodiment includes the following steps:

[0039] (1) Add 0.02kg of graphene oxide and 0.02kg of cetyltrimethylammonium bromide to 2L of ethanol, and perform ultrasonic oscillation for 3h at an ultrasonic frequency of 20kHz;

[0040] (2) Dry the ultrasonically oscillated solution obtained in step (1) at 50°C for 1 hour to obtain 0.02 kg of modified graphene oxide powder;

[0041] (3) Add 0.02 kg of the modified graphene oxide powder obtained in step (2) and 1.98 kg of nylon 12 into 25L ethanol, place them in a reaction kettle, mix and stir, pour in nitrogen and pressurize to 2.3MPa, and heat to 180°C, Until the nylon is completely dissolved, the mixed solution in the reactor is cooled to 120°C at a rate of 0.6°C / min in the first ...

Embodiment 2

[0046] The graphene oxide reinforced nylon material in this embodiment is composed of the following components and parts by weight: graphene oxide: 0.002 kg, and nylon 12: 1.998 kg.

[0047] The preparation method of graphene oxide reinforced nylon material in this embodiment includes the following steps:

[0048] (1) Add 0.002kg of graphene oxide and 0.1kg of octadecyltrimethylammonium chloride to 2L of acetone, and perform ultrasonic oscillation for 0.5h at an ultrasonic frequency of 100kHz;

[0049] (2) Dry the solution obtained in step (1) after ultrasonic vibration at 50° C. for 0.5 h to obtain 0.002 kg of modified graphene oxide powder;

[0050] (3) Add 0.002kg of the modified graphene oxide powder obtained in step (2) and 1.998kg of nylon 12 into 25L acetone, place them in a reaction kettle, mix and stir, blow in nitrogen, pressurize to 1.2MPa, and heat to 140°C, Until the nylon is completely dissolved, the mixed solution in the reactor is first cooled to 80°C at a rate of 0.3°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com