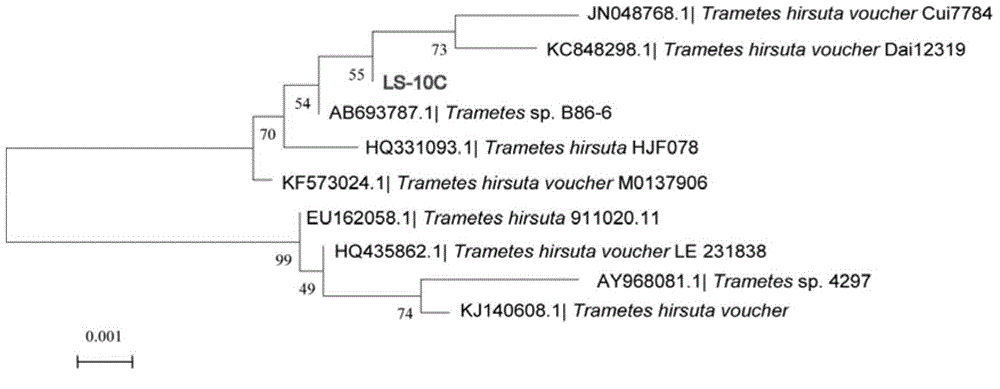

Trametes sp. and application thereof

A technology of Trametes and laccase, applied in Trametes and its application fields, can solve the problems of long fermentation time, high fermentation cost, low fermentation activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

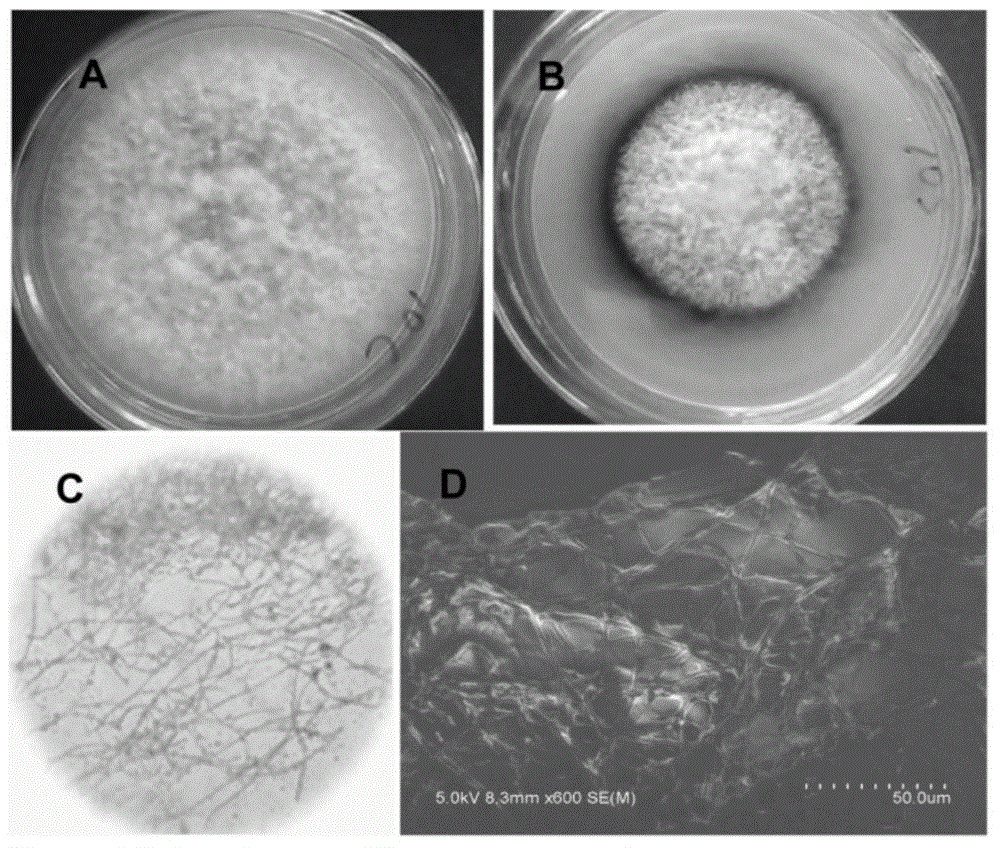

Embodiment 1

[0056] Take the ultra-low temperature (-80°C) glycerol freezing tube of the preserved Trametes trichotillobacter strain and dissolve it at room temperature, draw 0.1mL liquid to coat the PDA plate, incubate at 30°C for 5 days, wash the mycelium with sterile water, and use 5mL sterile water for each plate. Wash with water, absorb 2 mL of the mycelia suspension obtained after washing and insert it into 48 mL of sterile seed culture medium. Culture conditions: the culture temperature is 30°C, the rotation speed of the shaker is 220rpm, and after 48 hours of constant temperature cultivation, it becomes the seed culture solution for shaking flask fermentation to produce enzymes.

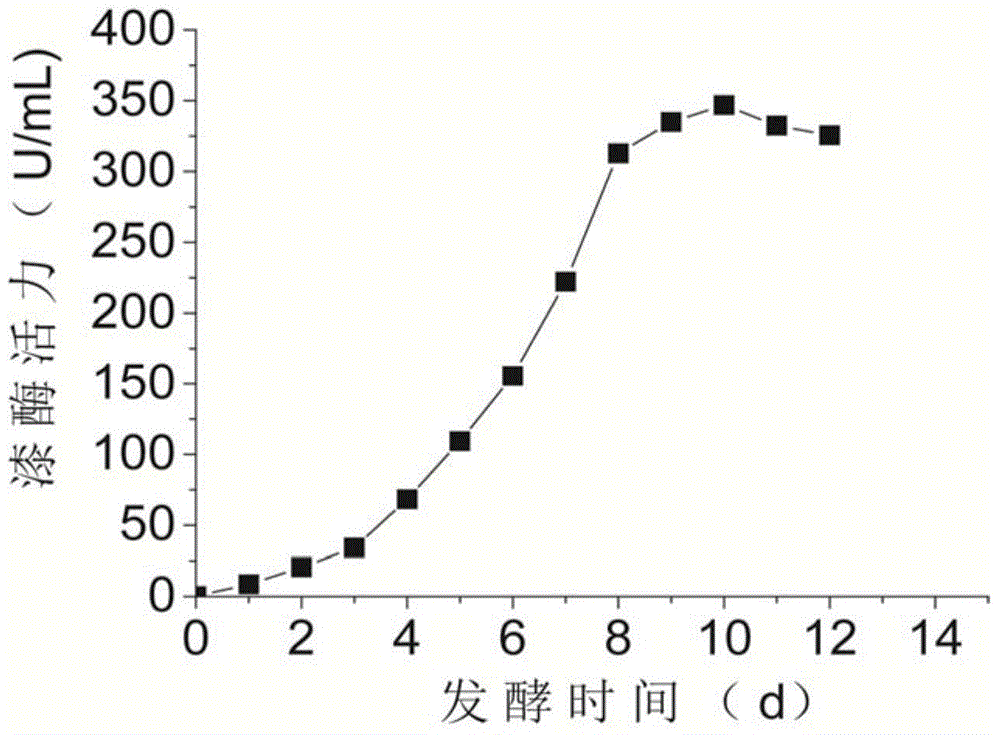

[0057] Put 45mL of enzyme-producing medium in a 250mL Erlenmeyer flask, insert 5mL of seed culture solution, and place in a shaking constant temperature culture for cultivation. Culture conditions: the culture temperature is 30° C., and the rotation speed of the shaker is 220 rpm. Under the above culture...

Embodiment 2

[0060] The seed culture liquid of shaking flask fermentation to produce enzyme is the same as embodiment 1

[0061] Put 45mL of enzyme-producing medium in a 250mL Erlenmeyer flask, insert 5mL of seed culture solution, and place in a shaking constant temperature culture for cultivation. Culture conditions: the culture temperature is 30° C., and the rotation speed of the shaker is 220 rpm. Under the above culture conditions, after 8 days of culture, the laccase activity in the fermentation broth was 304U / mL.

[0062] Each L of enzyme production medium contains: glucose 10g, 10% bran extract juice 100g, soybean meal 7g, yeast powder 2.5g, copper sulfate pentahydrate 0.25g, sodium chloride 1g, potassium dihydrogen phosphate 1g, calcium chloride 0.3g , pH5.5.

Embodiment 3

[0064] The seed culture liquid of shaking flask fermentation to produce enzyme is the same as embodiment 1

[0065] Put 45mL of enzyme-producing medium in a 250mL Erlenmeyer flask, insert 5mL of seed culture solution, and place in a shaking constant temperature culture for cultivation. Culture conditions: the culture temperature is 30° C., and the rotation speed of the shaker is 220 rpm. Under the above culture conditions, after 8 days of culture, the laccase activity in the fermentation broth was 326U / mL.

[0066] Each L of enzyme production medium contains: glucose 20g, 10% bran extract juice 120g, ammonium chloride 10g, yeast powder 3g, copper sulfate pentahydrate 0.25g, sodium chloride 1g, potassium dihydrogen phosphate 1g, calcium chloride 0.3 g, pH5.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com