Double metal hydroxide composite porous bismuth vanadate photoelectrode and preparation method thereof

A hydroxide, bimetal technology, applied in the direction of electrodes, electrode shapes/types, electrolytic components, etc., can solve the problems of high surface reaction energy barrier, weak charge conduction performance of bismuth vanadate, etc., to achieve low cost and improve energy utilization Efficiency, the effect of enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

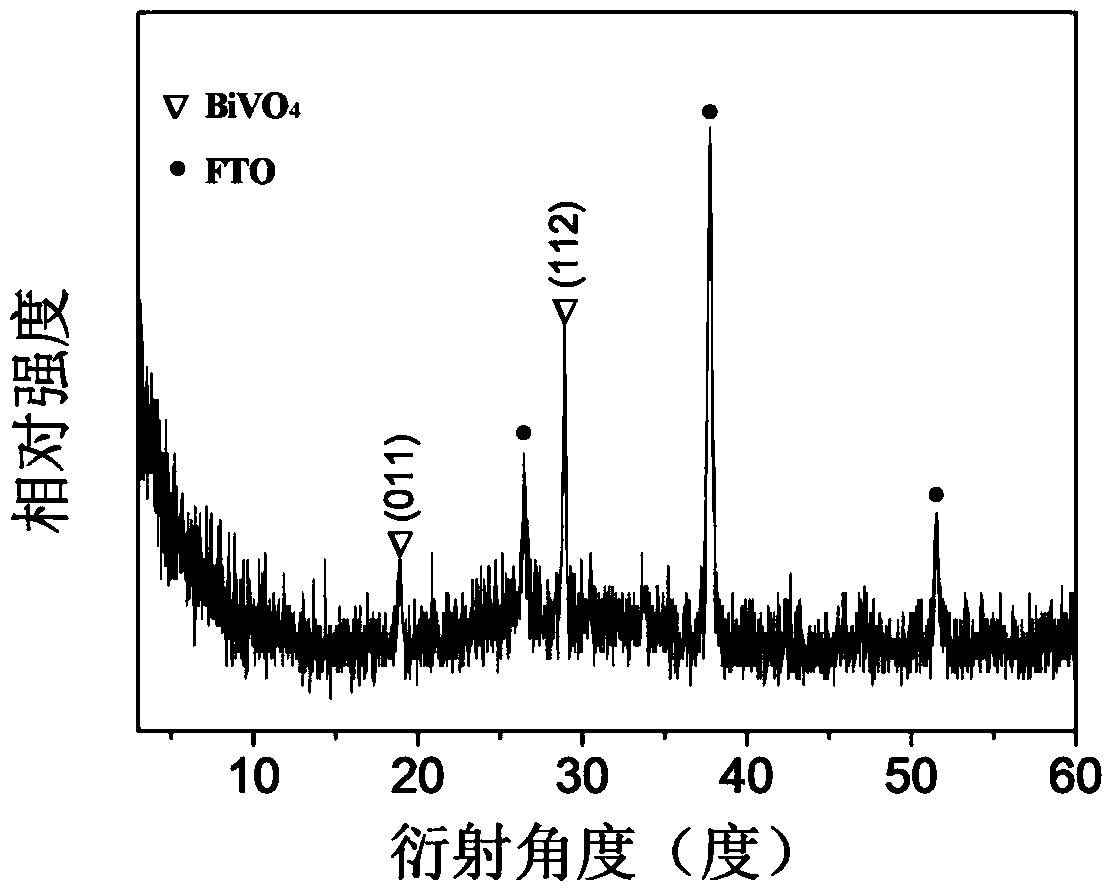

Embodiment 1

[0025] A. Weigh 0.4851g Bi(NO 3 ) 3 ·5H 2 O, 0.8925g Zn(NO 3 ) 2 ·6H 2 O was added to a mixed solution of 50mL deionized water and 100mL ethylene glycol to prepare a mixed salt solution;

[0026] B. Use acetone: isopropanol: water = 1:1:1 volume ratio solution to ultrasonically clean FTO (fluorine-doped SnO 2 conductive glass) conductive glass sheet, and naturally dry the conductive glass sheet; the mixed salt solution of step A is transferred to the three-electrode electrolytic cell, with the conductive glass substrate as the working electrode, wherein the working area of the conductive glass sheet is 2cm 2 . With Ag / AgCl as the reference electrode, platinum wire as the counter electrode, and the electrolytic cell as a single-chamber electrolytic cell, an electrochemical workstation is used to apply a constant negative potential of 0.01V to the working electrode, and the total charge of electrodeposition is -8.35×10 -2 C·cm -2 . Take out the deposited electrode, wa...

Embodiment 2

[0031] A. Weigh 0.4851gBi (NO 3 ) 3 ·5H 2 O, 0.595g Zn(NO 3 ) 2 ·6H 2 O was added to a mixed solution of 50mL deionized water and 100mL ethylene glycol to prepare a mixed salt solution;

[0032] B is the same as embodiment 1, and the difference is that the working area of the conductive glass is 1.5cm 2 , the total deposited charge of electrodeposition is -10×10 -2 C·cm -2

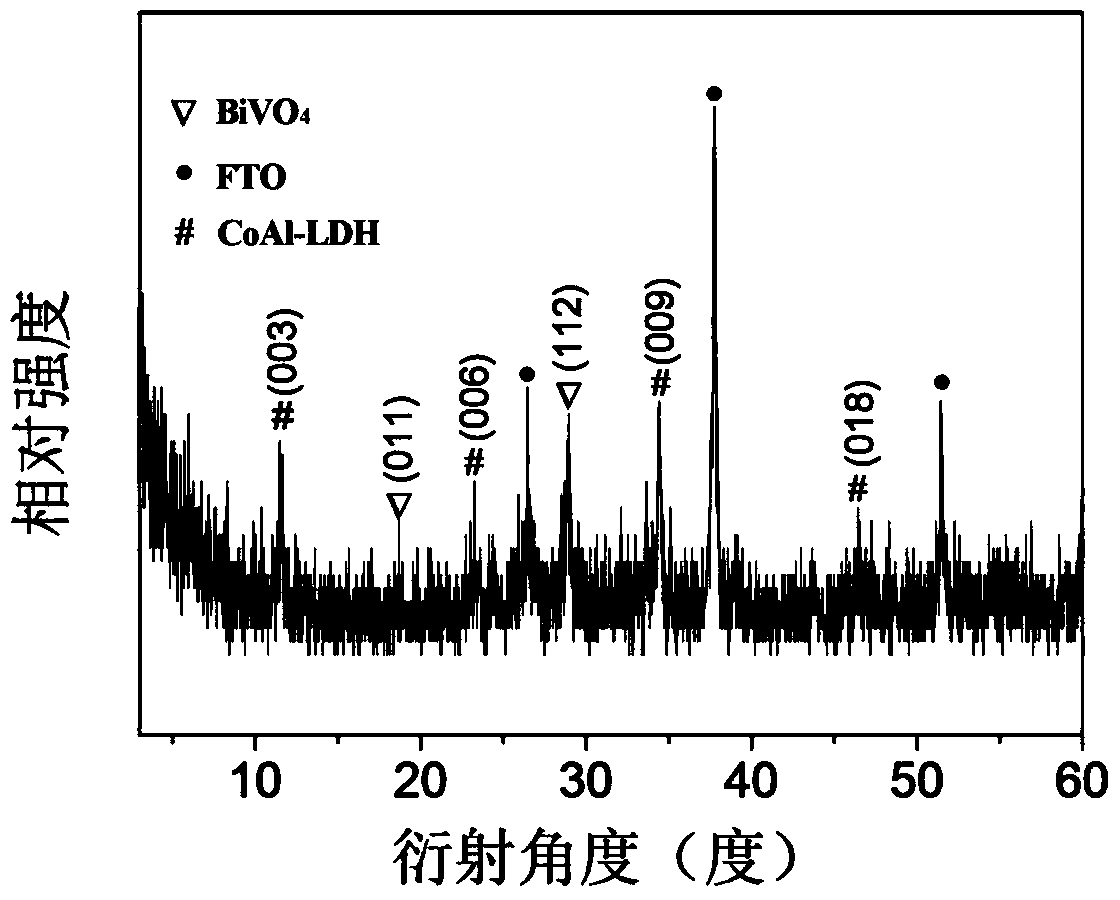

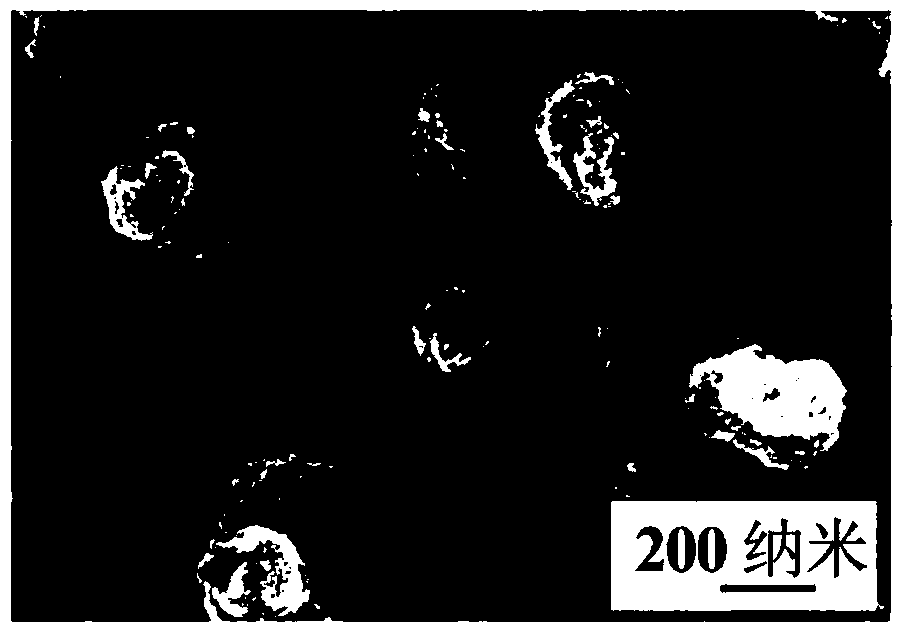

[0033] C. Weigh 0.1393g vanadium acetylacetonate and dissolve it in 2mL dimethyl sulfoxide, add 150μL of the solution dropwise to the electrode sheet obtained in step B, then calcinate in a muffle furnace at 450°C for 2 hours, and wait until the temperature drops to room temperature Then take it out; weigh 4g NaOH, dissolve it in 100mL deionized water, add the calcined electrode sheet in step C, stir gently for 1 hour, take out the electrode sheet, rinse it with deionized water, and dry it at 70°C for 0.5 hour to get Porous BiVO 4 An electrode with an average particle size of 260nm and a pore s...

Embodiment 3

[0037] A. Weigh 0.4851gBi(NO 3 ) 3 ·5H 2 O, 0.2975g Zn(NO 3 ) 2 ·6H 2 O was added to a mixed solution of 50mL deionized water and 100mL ethylene glycol to prepare a mixed salt solution;

[0038] B is the same as Example 1, except that the constant negative potential used for electrodeposition is-0.18V, and the total deposition charge of electrodeposition is-9×10 -2 C·cm -2

[0039] C. Weigh 0.1393g of vanadium acetylacetonate and dissolve it in 2mL of dimethyl sulfoxide, add 200μL of the solution dropwise to the electrode sheet obtained in step B, then calcinate in a muffle furnace at 450°C for 3 hours, and wait until the temperature drops to room temperature Then take it out; weigh 4g NaOH, dissolve it in 100mL deionized water, add the calcined electrode sheet in step C, stir gently for 1 hour, take out the electrode sheet, rinse it with deionized water, and dry it at 70°C for 0.5 hour to get Porous BiVO 4 An electrode with an average particle size of 236nm and a por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com