A method for preparing graphene from biomass waste

A biomass and graphene technology, applied in the field of graphene preparation, can solve the problems of high raw material cost, low graphene output, and high equipment requirements, and achieve the effects of reducing pollution, low cost, and reducing oxygen-containing groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

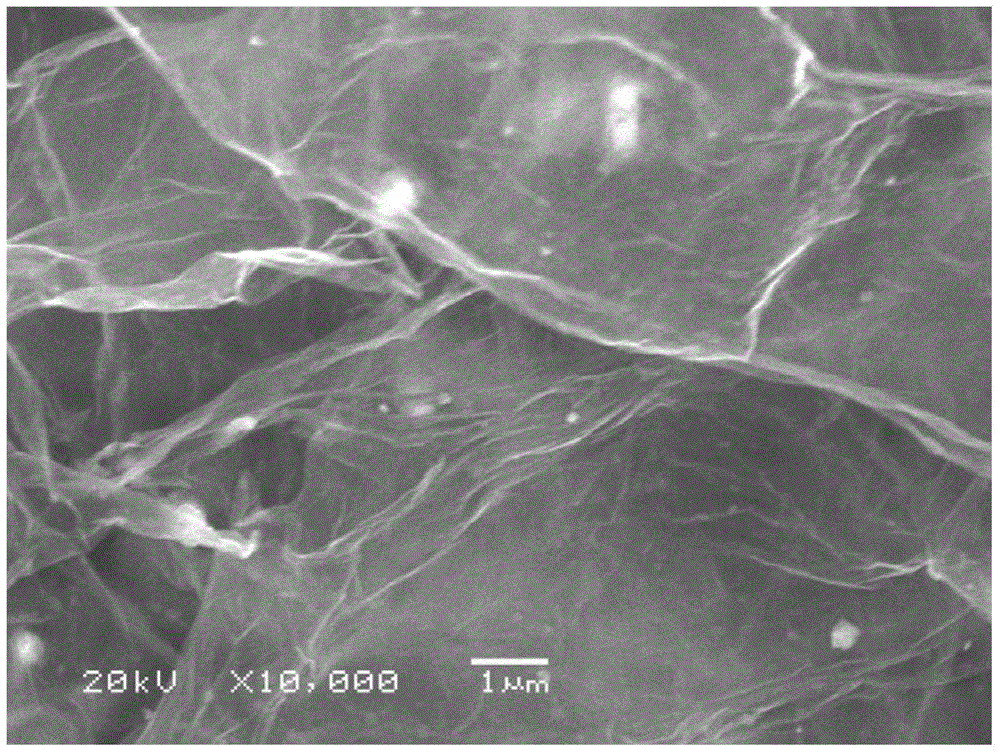

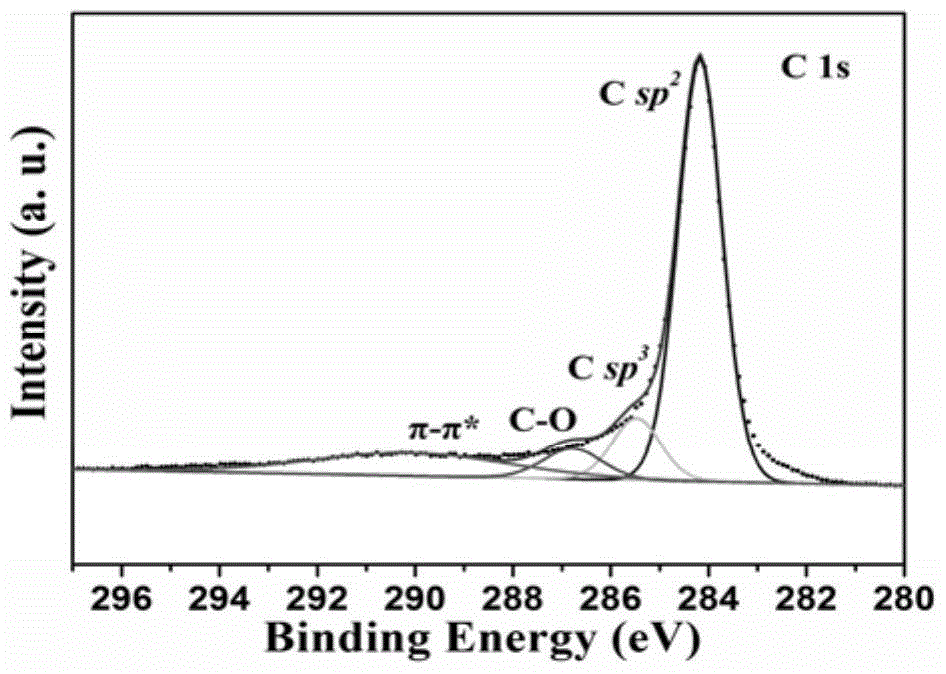

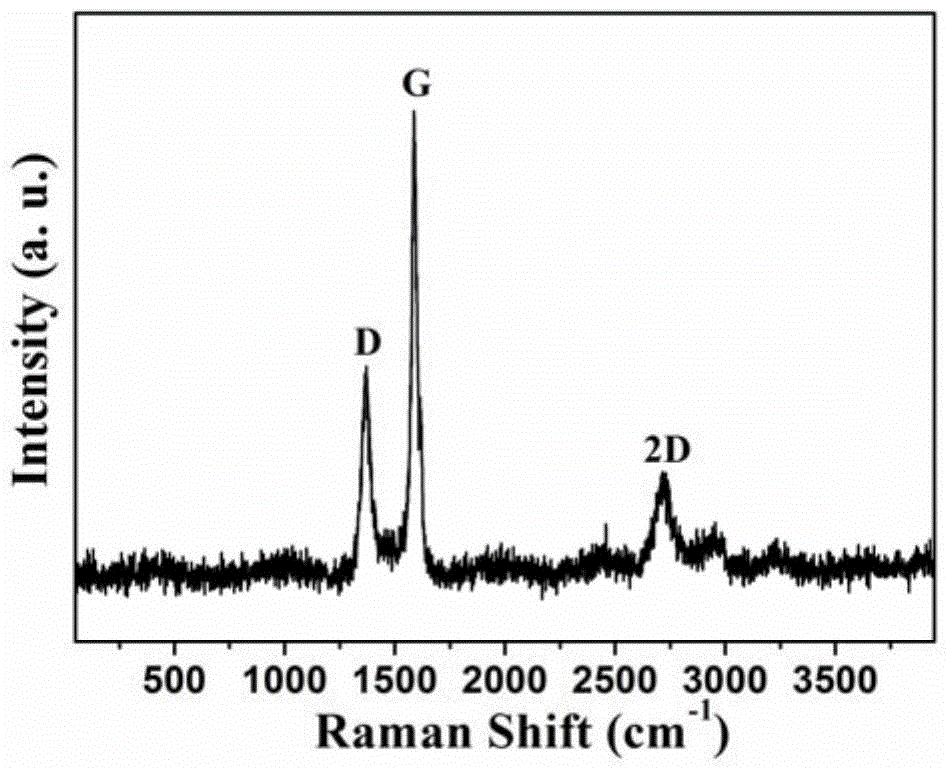

Image

Examples

Embodiment 1

[0066] Embodiment 1: Graphene preparation with rice straw as raw material

[0067] Step 1: Soak 40-80 mesh rice straw in water 8-10 times its mass for 3 days, add slaked lime equivalent to 35% of its mass, stir evenly, then heat to 95-100°C and keep it warm for 3 hours before filtering , to obtain solid residue and yellow viscous liquid.

[0068] In the second step, the solid residue is placed in hydrofluoric acid with a concentration of 25% at a liquid-solid ratio of 3:1, treated at 70°C for 60 minutes, and then the liquid-solid ratio is diluted to 20:1, and treated for 90 minutes under boiling conditions. Filtration to obtain desiliconization hydrolysis residue;

[0069] The third step is to carbonize the desiliconized hydrolysis slag obtained in the second step. Under the protection of nitrogen at a flow rate of 400 sccm, the temperature was raised to 400° C. at a rate of 5° C. / min, and then kept for 2 hours to obtain a carbonized material.

[0070] Step 4: Treat the car...

Embodiment 2

[0074] Embodiment 2: Graphene preparation with bamboo product processing waste as raw material

[0075] Step 1: soak 40-80 mesh bamboo product processing waste in water 8-10 times its mass for 3 days, add slaked lime equivalent to 35% of its mass, stir evenly, then heat to 95-100°C and keep it warm After 4h, solid residue and yellow viscous liquid were obtained.

[0076] In the second step, the solid residue is placed in hydrofluoric acid with a concentration of 25% at a liquid-solid ratio of 3:1, treated at 70°C for 60 minutes, and then the liquid-solid ratio is diluted to 20:1, and treated for 150 minutes under boiling conditions. Filtration to obtain desiliconization hydrolysis residue;

[0077] The third step is to carbonize the desiliconized hydrolysis slag obtained in the second step. Under the protection of high-purity hydrogen with a flow rate of 400 sccm, the temperature was raised to 600 °C at a rate of 10 °C / min, and then kept for 4 hours to obtain a carbonized ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com