Industrial circulating cooling water system

A circulating cooling water, industrial technology, applied in water shower cooler, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of rising cost of raw water, soft texture, and intensified equipment corrosion. , to improve the effect of adsorption and filtration, use time, low application cost, and avoid pipeline blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

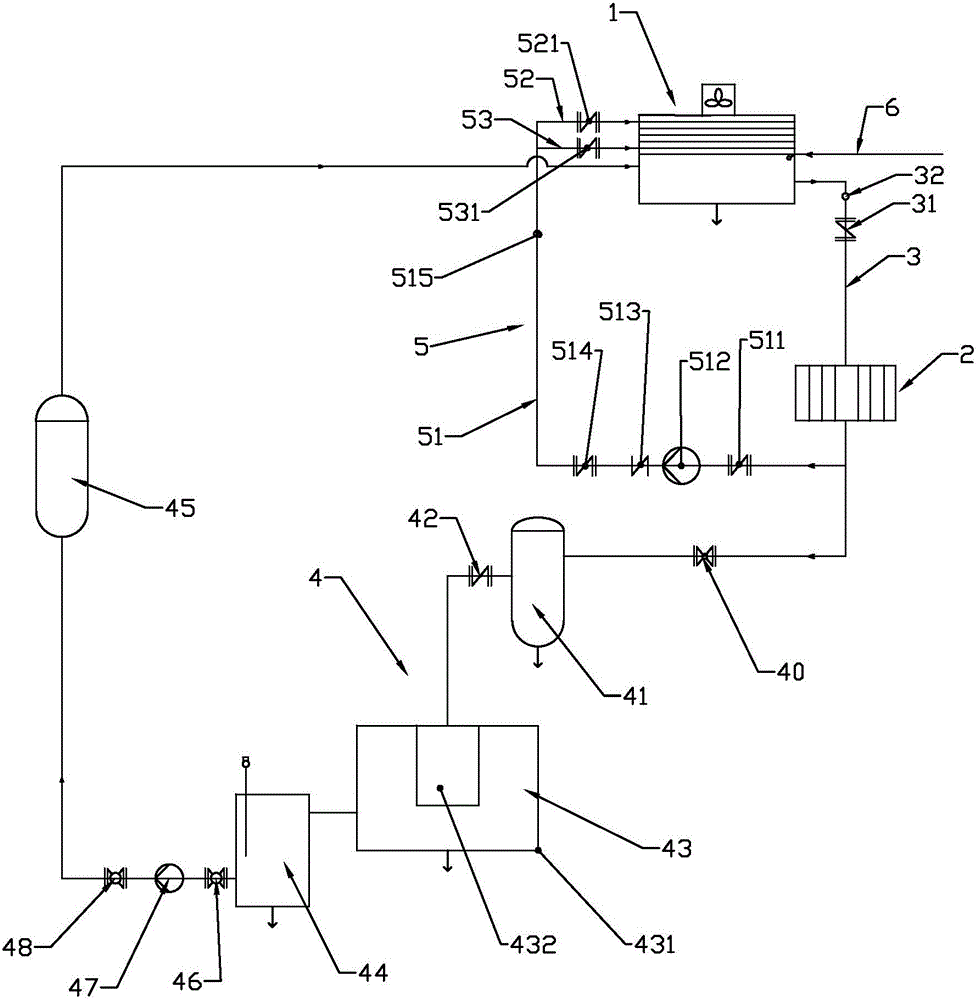

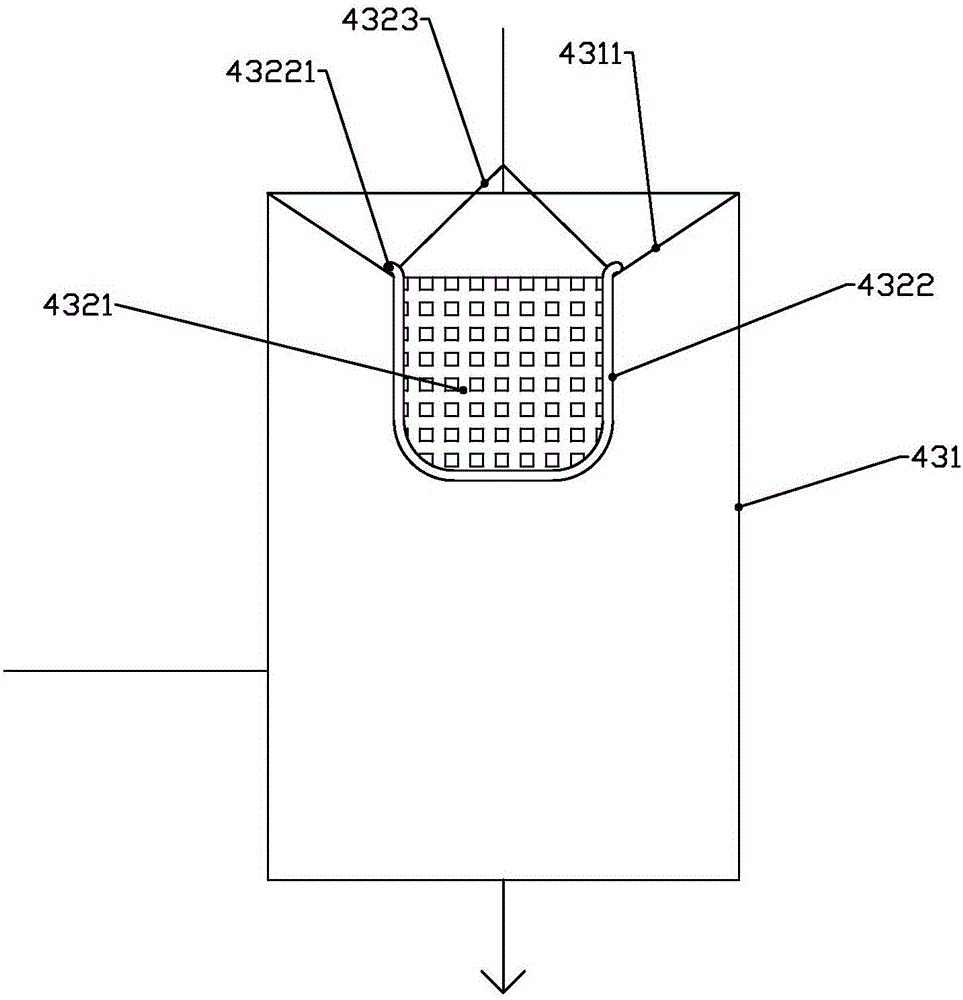

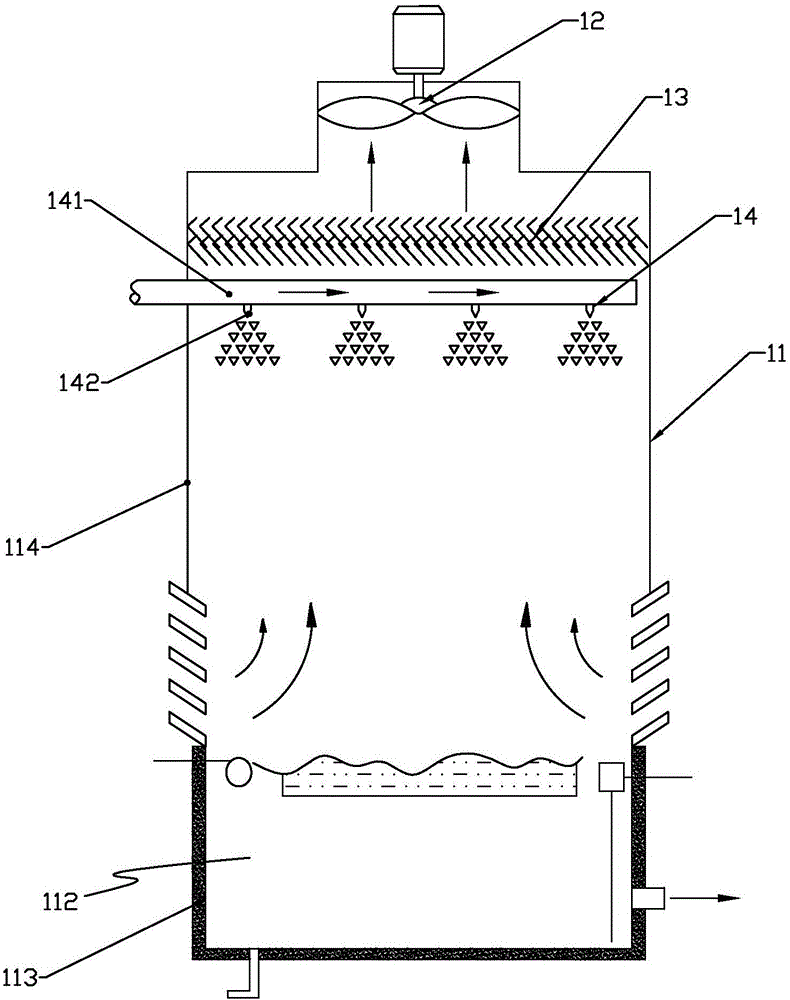

[0036] Such as Figure 1 to Figure 5 As shown, a kind of industrial circulating cooling water system disclosed by the present invention includes a cooling tower 1, a water supply pipeline 3 leading to the water point 2, a filtered water circulation pipeline 4 connecting the water point 2 and the cooling tower 1, and a water supply line 4 leading to the cooling tower 1. The raw water supply pipeline 6 for supplementing the water volume; the water supply pipeline 3 is connected to the water outlet of the cooling tower 1, and the water supply pipeline 3 includes an on-off control valve 31 connected in series to control the on-off of the water supply pipeline, and the on-off control valve 31 is a butterfly valve , the filtered water circulation pipeline 4 comprises a throttle valve 40, a side filter device 41, a water circulation pipeline shut-off valve 42, a bamboo charcoal filter tank 43 with bamboo charcoal as a filter material, a sludge sedimentation tank 44, and a pipeline shu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com