Feldspar waste material concrete and preparation method thereof

A concrete and waste technology, applied in the field of feldspar waste concrete and its preparation, can solve the problems of waste pollution, less consumption, etc., and achieve the effects of good water resistance, improved compressive performance, and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

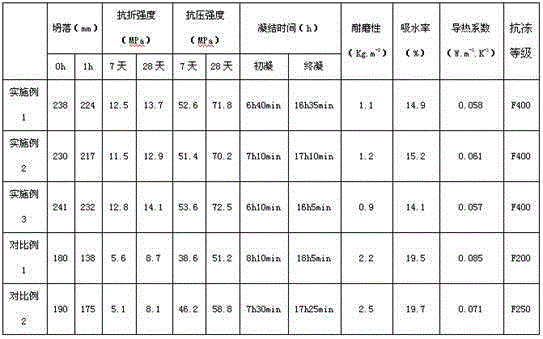

Examples

Embodiment 1

[0023] A kind of feldspar waste concrete of the present invention, each raw material weight part is made up of: feldspar waste 830, clay 165, cement 300, phenolic fiber 40, polyvinylidene chloride fiber 27, water 85 and admixture 5.0, admixture is made of carbonyl coke 7.1 parts of aldehyde superplasticizer, 5.9 parts of sodium metaaluminate accelerator, 9.02 parts of citric acid-chitosan adhesive and 10.0 parts of diatomite powder;

[0024] Preparation method of citric acid-chitosan adhesive: Dissolve citric acid in water at a mass ratio of 1:4, stir until a uniform solution is formed, then add chitosan with 20% mass of citric acid, and stir until chitosan Just dissolve completely, and store in a sealed container at 4-10°C.

[0025] P.O42.5 Ordinary Portland cement, polyvinylidene chloride fiber length is 8-10mm, phenolic fiber length is 3-5mm.

[0026] The preparation steps are:

[0027] (1) Grinding: Weigh the feldspar waste, crush it until the particle size is less than ...

Embodiment 2

[0031] A kind of feldspar waste concrete of the present invention, each raw material weight part is made up of: feldspar waste material 800, clay 150, cement 280, phenolic fiber 35, polyvinylidene chloride fiber 25, water 80 and admixture 4.75, admixture is made of carbonyl coke Composed of 6.7 parts of aldehyde superplasticizer, 5.8 parts of sodium metaaluminate accelerator, 8.45 parts of citric acid-chitosan adhesive and 9.8 parts of diatomaceous earth powder;

[0032] The preparation method of the citric acid-chitosan adhesive is the same as in Example 1, P.O42.5 ordinary Portland cement, the length of the polyvinylidene chloride fiber is 8-10 mm, and the length of the phenolic fiber is 3-5 mm.

[0033] The preparation steps are the same as in Example 1.

Embodiment 3

[0035] A kind of feldspar waste concrete of the present invention, each raw material weight part is made up of: feldspar waste material 850, clay 180, cement 320, phenolic fiber 45, polyvinylidene chloride fiber 30, water 95 and admixture 5.25, admixture is made of carbonyl coke Composed of 7.5 parts of aldehyde superplasticizer, 6.1 parts of sodium metaaluminate accelerator, 9.55 parts of citric acid-chitosan adhesive and 10.2 parts of diatomaceous earth powder;

[0036] The preparation method of the citric acid-chitosan adhesive is the same as in Example 1, P.O42.5 ordinary Portland cement, the length of the polyvinylidene chloride fiber is 8-10 mm, and the length of the phenolic fiber is 3-5 mm.

[0037] The preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com