High-temperature-resistant filtrate reducer and preparation method thereof

A filtrate reducer and anti-high temperature technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as low recovery rate, formaldehyde is easy to pollute the environment, destroy ecological balance, etc., and achieve mild and controllable reaction conditions , The preparation method is simple and easy, and the effect of improving the temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

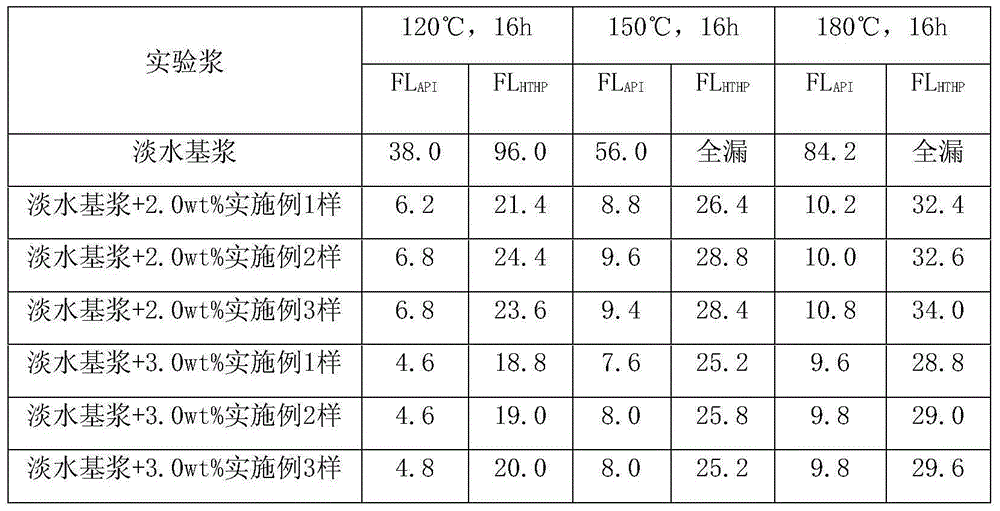

Examples

Embodiment 1

[0021] The anti-high temperature fluid loss reducer provided by the invention is composed of lignin, acrylamide, p-cresol and 2-acrylamido-2-methylpropanesulfonic acid, wherein the consumption of each component is: lignin 25g, 10 g of acrylamide, 5 g of p-cresol, and 10 g of 2-acrylamido-2-methylpropanesulfonic acid.

[0022] The preparation method of the anti-high temperature fluid loss reducer of the present invention, its specific method is as follows:

[0023] The first step is to filter the papermaking black liquor to remove impurities, heat to 75°C, add sulfuric acid to adjust the pH value to 4.0, bake at 60°C for 1.0h until fine reddish-brown precipitates are precipitated, and centrifuge to obtain lignin, vacuum at room temperature Dry to constant weight;

[0024] Take 10g of 2-acrylamido-2-methylpropanesulfonic acid to make a 15.0wt% solution in water, neutralize it with 50.0wt% KOH solution to a pH value of 7.0, and dry it in a vacuum oven until constant Weight, to ...

Embodiment 2

[0029] The anti-high temperature fluid loss reducer provided by the present invention is composed of lignin, acrylamide, p-cresol and 2-acrylamido-2-methylpropanesulfonic acid, wherein the amount of each component is: lignin 115g , 40 g of acrylamide, 15 g of p-cresol, and 60 g of 2-acrylamido-2-methylpropanesulfonic acid.

[0030] The preparation method of the anti-high temperature fluid loss reducer of the present invention, its specific method is as follows:

[0031] The first step is to filter the papermaking black liquor to remove impurities, heat to 75°C, add sulfuric acid to adjust the pH value to 4.0, bake at 60°C for 1.0h until fine reddish-brown precipitates are precipitated, centrifuge to obtain lignin, and vacuum at room temperature Dry to constant weight;

[0032] Take 60g of 2-acrylamido-2-methylpropanesulfonic acid to make a 15.0wt% solution in water, neutralize it with 50.0wt% KOH solution to a pH value of 7.0, and dry it in a vacuum oven until constant Weigh...

Embodiment 3

[0037]The anti-high temperature fluid loss reducer provided by the present invention is composed of lignin, acrylamide, p-cresol and 2-acrylamido-2-methylpropanesulfonic acid, wherein the amount of each component is: lignin 80g , 30 g of acrylamide, 10 g of p-cresol, and 40 g of 2-acrylamido-2-methylpropanesulfonic acid.

[0038] The preparation method of the anti-high temperature fluid loss reducer of the present invention, its specific method is as follows:

[0039] The first step is to filter the papermaking black liquor to remove impurities, heat to 75°C, add sulfuric acid to adjust the pH value to 4.0, bake at 60°C for 1.0h until fine reddish-brown precipitates are precipitated, centrifuge to obtain lignin, and vacuum at room temperature Dry to constant weight;

[0040] After taking 40g of 2-acrylamido-2-methylpropanesulfonic acid and making a 15.0wt% solution in water, neutralize it with 50.0wt% KOH solution to a pH value of 7.0, place it in a vacuum oven and dry it to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com