Preparation method of PBS (poly butylenes succinate)

A technology of polybutylene succinate and butanediol, which is applied in the field of preparation of polybutylene succinate, can solve problems affecting product hue, intrinsic viscosity, decarboxylation, and limited applications, and achieve the solution of catalytic The efficiency and selectivity are low, the effect of increasing polycondensation selectivity and improving polycondensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

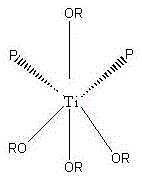

Method used

Image

Examples

Embodiment 1

[0022] A total of 1316g of succinic acid and butanediol was added to the reaction device, wherein the molar ratio of succinic acid to butanediol was 1.3:1, and 0.74g of titanium-phosphorus composite catalyst was added, under a pressure of 78kPaA and a temperature of 155°C Negative pressure esterification reaction was carried out for 3.5 hours, then the temperature was raised to 205° C., and the pressure was reduced to 3 kPaA to carry out polycondensation reaction for 2.5 hours to obtain polybutylene succinate, which can be called PBSA. After testing, the obtained polybutylene succinate had a number average molecular weight of 108,000, a tensile strength of 36.2 MPa, and an elongation at break of 263%.

Embodiment 2、3、4

[0024] Embodiment 2, 3, 4 is on the basis of embodiment 1, the proportioning of succinic acid and butanediol is adjusted, is respectively 1.2:1, 1.8:1, 2.2:1, and raw material and process condition are unchanged , to obtain polybutylene succinate, which can be called PBSB, PBSC, and PBSD respectively.

Embodiment 5

[0026] On the basis of Example 2, the amount of the catalyst was adjusted to 3% of the moles of succinic acid used, the esterification reaction was carried out at a temperature of 135°C and a pressure of 40kPaA for 4 hours, and the polycondensation reaction was carried out at a temperature of 210°C and a pressure of 4kPaA After 2 hours, polybutylene succinate was obtained, which can be called PBSE.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com